Scanning Electron Microscopy (SEM) for Battery Electrode Analysis

Home » Scanning Electron Microscopy (SEM) for Battery Electrode Analysis

SEM enables failure analysis of aged cells, quality control of manufactured

electrodes, and fundamental research on material degradation mechanisms.

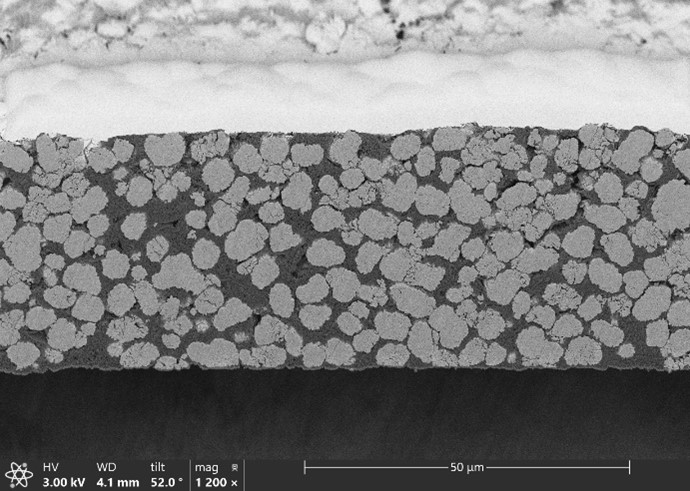

Battery performance, lifetime, and safety are heavily influenced by the morphology and microstructure of the electrode materials. Scanning Electron Microscopy (SEM) provides high-resolution imaging and elemental analysis capabilities, making it a critical tool for evaluating both pristine and cycled battery electrodes.

This application note outlines how SEM can be used to characterize battery electrodes, highlights key preparation methods, imaging techniques, and typical analysis goals.

SEM is used to investigate the following properties of battery electrodes:

- Surface morphology and porosity

- Particle size and shape distribution

- Electrode coating uniformity and thickness

- Interface degradation (e.g., between active material and binder/current collector)

- Formation of surface layers (e.g., SEI on anode)

- Elemental composition using Energy Dispersive X-ray Spectroscopy (EDS/EDX)

- Structural changes after cycling (cracking, delamination, etc.)

Download the application note to learn more.

Would you like to learn more about battery materials analysis?

Contact us today for your battery materials analysis needs. Please complete the form below to have an EAG expert contact you.