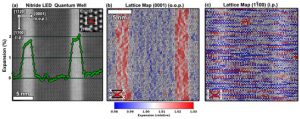

A Picture is Worth a Thousand Words – TEM, STEM and AC-STEM

TEM, STEM and AC-STEM techniques deliver high resolution images providing a detailed view of a material or product.

EAG’s analytical support services for lighting result in production cost savings, improved lot-to-lot product performance and accelerated product development. We provide world-leading support of research, development and fast-response production monitoring for both conventional and LED lighting manufacturing.

EAG has a long history in the field of lighting testing and analysis, supporting both conventional and LED lighting product development. Our experts provide consulting services for lighting products and raw materials, due to our vast knowledge of application conditions and regulations for lighting materials.

WE KNOW HOW to improve your performance.

EAG offers a comprehensive suite of services for the lighting industry, meeting the industry’s exacting standards for tight controls of material properties, composition and chemistry. Here are just a few ways we can help for both conventional and LED applications:

We support LED analysis at all levels:

We offer the following range of services to answer questions and address issues related to all LED product component and materials at different manufacturing stages.

We offer identification and compositional analysis of polymers (e.g. silicones), metals, gases, LED phosphors, quantum dots, ceramics, contaminants and electrical components.

We offer measurement of light technical parameters of a single LED and complete modules before, during and after testing (e.g. color temperature, color point, luminous intensity, radiation pattern, color over angle, etc.).

Our lighting and LED expertise also enables us to successfully address issues in related industries that have components containing similar materials, or where the products may also be exposed to harsh environments, e.g. automotive components, including lighting, photovoltaic/solar cells, thermal/solar concentrators/mirrors, etc.

Our conventional lighting experts have years of experience troubleshooting and testing conventional lighting products, including:

These types of products often require compositional analyses, such as identifying and characterizing such components of conventional lighting materials such as metals, gases, fluorescent powders, emitter, mercury consumption, tungsten electrodes/materials, pre-coats, feed-through materials, ceramics, glass, contaminants

or electrical components.

Examples of quality control and contamination studies for conventional lighting products:

EAG offers surface and thin film characterization to understand composition, surface contamination and surface topography, as well as measuring thin film thickness, defects and optical properties. Our analytical support for LED R&D includes packaging development and contamination analysis, in addition to burn-in and reliability testing to LM-80 standards. EAG scientists are experts in the characterization of epitaxial films for identity, structure, grain size and orientation, composition, dopants and contaminants.

We offer a broad range of analytical services developed exclusively for LED characterization:

We understand the need for first-to-market breakthrough technologies, and EAG can collaborate to provide results-driven solutions to the most complex of analytical investigations. Our experienced experts will work with your team to troubleshoot and choose the right material for your application or improve a manufacturing process.

Contact us today for your LED and lighting analytical needs. Please complete the form below to have an EAG expert contact you.

TEM, STEM and AC-STEM techniques deliver high resolution images providing a detailed view of a material or product.

In this application note, we show the possibility to extract distance information at an atom-column to atom-column basis with picometer level precision.

In the full webinar we introduce MicroLED Analysis for improved understanding of III-nitride material properties and growth/device processes

APT is a nanoscale materials analysis technique that provides 3D spatial imaging and chemical composition measurements with high sensitivity simultaneously.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.