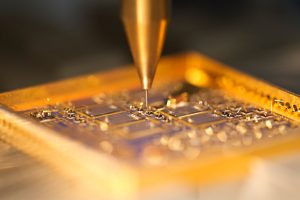

2D and 3D Investigations of Li-Ion Battery Electrodes

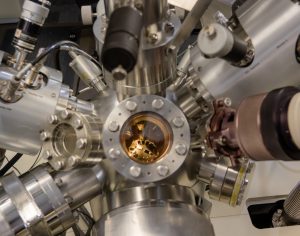

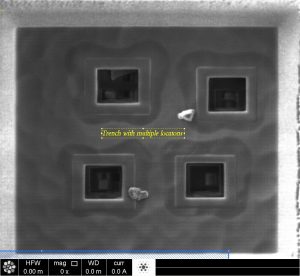

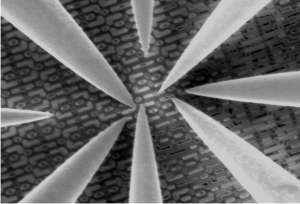

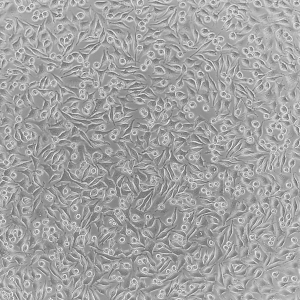

Li-Ion electrodes are more than just energy suppliers; they’re intricate mazes of structures and materials. Their design and intricate layout play pivotal roles in determining a battery’s capacity, discharge rate, and overall lifespan.