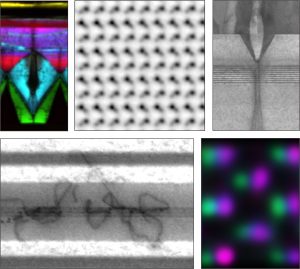

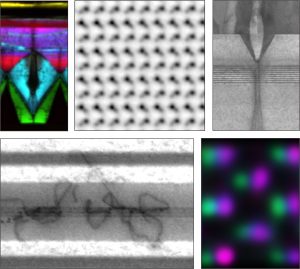

Advanced Microscopy of Compound Semiconductors

In this webinar, we will explore the variety of microscopy techniques available at Eurofins EAG commonly utilized to characterize compound semiconductor materials.

Consumer electronics testing has been an important part of EAG for over 30 years, and we offer the most comprehensive suite of testing techniques for characterization of consumer electronics. We understand the need for first-to-market breakthrough technologies, as well as the challenges of maintaining supply chain quality and efficiency from international providers.

With laboratories located around the world, EAG scientists have supported customers creating products for consumer electronics such as mobile devices, tablets, computers, wearables, and health tracking devices. Over the years, we’ve earned a reputation worldwide for developing new methods to advance consumer electronics product development and for solving materials-related issues. WE KNOW HOW to pursue intense electronics innovation but still ensure consumer product safety and quality.

Eurofins EAG Laboratories offers a comprehensive suite of services for the consumer electronics industry, meeting the industry’s exacting standards for tight controls of material properties, composition and chemistry. Here are just a few examples of how we can help:

EAG Laboratories has a wide range of experience testing wearable technologies such as Augmented Reality (AR), Virtual Reality (VR), and Mixed Reality (VR) for many of our customers. We strive to partner with our customers to support product development, safety, and quality. Our services cover the complete value chain, such as supply chain auditing and quality control by certifying the quality of raw materials supplied, testing of electronic components, investigation of field failures, through to protection of intellectual property.

Additionally, wearable products can come into intimate contact with prolonged consumer exposure. The risk of exposure to chemicals resulting in sensitization and irritation is increased based on the customer experience. We have developed an effective and efficient process for assessing biocompatibility for Consumer Product Safety Commission. Our team of scientists can perform chemical characterization to identify residual chemicals, assess toxicological risk, and provide insight into potential safety issues. We also evaluate the biocompatibility of skin-contacting products sold to consumers using in vitro models to assist clients in the risk management process.

Our labs perform failure analysis on both integrated circuits and devices. The failure analysis services range from Level 1 non-destructive examination to Level 3 fault isolation and root cause identification and characterization.

Investigation of materials-related issues includes organic analysis of plastics/polymers, flux, lubricants and solder masks, as well as elemental analysis of wire bonds, bond pads, leads and lead frames.

We use GC/MS, LC/MS, ICP/MS, and in vitro biocompatibility testing to determine if any transferred chemicals are skin sensitizers with potential for toxic, allergenic or abrasion concerns.

Inspection of raw materials during key phases of manufacturing can aid in the identification and elimination of unwanted impurities in final products.

Microscopy techniques are essential to investigate sample micro-structure, morphology, particle size, particle coatings and defects in thin/thick film or bulk substrate samples.

We compare“good” vs “bad” samples to evaluate chemical changes by applying a variety of analytical and physical testing techniques

EAG solves surface chemistry issues with adhesion and bonding, answering questions regarding surface cleanliness and investigations regarding morphology and topography of materials’ surfaces

Investigation of materials-related issues includes organic analysis of plastics/polymers, flux, lubricants and solder masks, as well as elemental analysis of wire bonds, bond pads, leads and lead frames.

EAG scientists have the expertise to solve difficult challenges with coatings such as paints and adhesives. We provide depth-specific distribution measurements and chemical survey characterizations of coatings.

Our team offers the engineering expertise to design, develop, test, analyze, and debug the most innovative products using ATE, system-level testing, reliability and IC-level failure analysis.

We provide end-to-end EMC/EMI testing solutions to evaluate components for use in extreme conditions to help avoid unexpected electromagnetic interference & compatibility compliance issues.

Litigation support services provide scientific expertise, data interpretation, analytical litigation support, or provide an expert witness testimony.

Download the Consumer Electronics Brochure Today!

EAG can collaborate to provide results-driven solutions to the most complex of analytical investigations. Our experienced experts will work with your team to troubleshoot and choose the right material for your application or improve a manufacturing process.

Contact us today for your consumer product testing needs. Please complete the form below to have an EAG expert contact you.

In this webinar, we will explore the variety of microscopy techniques available at Eurofins EAG commonly utilized to characterize compound semiconductor materials.

In Vitro Diagnostics test and system development support from the materials sciences experts at EAG Laboratories, contact us today!

Analytical testing to support changes in raw materials and processing conditions used in manufacturing memory foam, as well as odor

February 12, 2025

During this live Ask the Expert event, we will answer pre-submitted questions from our audience regarding Silicon Carbide for High Powered Electronics. EAG Laboratories has a vast depth of experience analyzing silicon carbide using both bulk and spatially resolved analytic techniques and is the world-leading materials characterization and engineering resource for semiconductor testing.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.