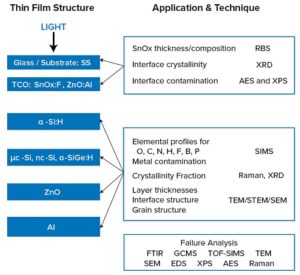

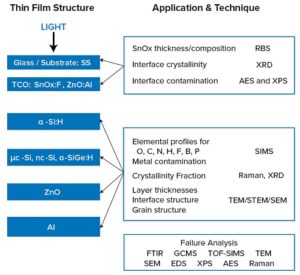

Surface Analysis of α-Si, µc-Si Thin Film PV

Surface analysis lab techniques on α-Si thin film PV, microcrystalline Si, nanocrystalline Si, amorphous SiGe, & microcrystalline SiC

Eurofins EAG Laboratories is active in the energy testing industry, particularly in regards to lithium-ion batteries, photovoltaics, HBLED’s, and fuel cell analysis. Our scientists and engineers help manufacturers to pursue state-of-the-art R&D, and we understand the need for first-to-market breakthrough technologies, as well as the challenges of maintaining supply chain quality and efficiency from international providers.

EAG has worked with the world’s leading HBLED manufacturers to increase efficiency and yield. Lithium-ion batteries are used in a wide range of today’s mobile devices, due to their light weight and high charge density. In recent years, there have been significant technological advances, driven mainly to support electrification of vehicles, which require high power and energy with exceptional safety standards. To achieve these goals, it is essential have a good understanding of electrochemical processes that occur when batteries undergo a charge/discharge cycle. In addition, the quality of the raw materials used for battery manufacturing needs to be carefully controlled to ensure consistent and predictable performance.

WE KNOW HOW to improve your performance.

EAG offers a comprehensive suite of services for the energy industry, meeting the industry’s exacting standards for tight controls of material properties, composition and chemistry. Here are just a few ways we can help:

Inspection of raw materials during key phases of manufacturing can aid in the identification and elimination of unwanted impurities in final products.

Our labs perform failure analysis on both integrated circuits and devices. The failure analysis services range from Level 1 non-destructive examination to Level 3 fault isolation and root cause identification and characterization.

Investigation of materials-related issues includes organic analysis of plastics/polymers, flux, lubricants and solder masks, as well as elemental analysis of wire bonds, bond pads, leads and lead frames.

Microscopy techniques are essential to investigate sample micro-structure, morphology, particle size, particle coatings and defects in thin/thick film or bulk substrate samples.

Compositional analysis can be used to determine the components of an unknown and suspect material and to identify differences between similar materials such as the lithium content of an electrode.

EAG solves surface chemistry issues with adhesion and bonding, questions regarding surface cleanliness and investigations regarding morphology and topography of materials’ surfaces

EAG scientists have the expertise to solve difficult challenges with coatings, such as paints and adhesives. We provide depth-specific distribution measurements and chemical survey characterizations of coatings.

Our team offers the engineering expertise to design, develop, test, analyze, and debug the most innovative products using ATE, system-level testing, reliability and IC-level failure analysis.

EAG provides end-to-end EMC/EMI energy testing solutions to evaluate components for use in extreme conditions to help avoid unexpected electromagnetic interference and compatibility compliance issues.

We provide world-leading support of research, development and fast-response production monitoring for both conventional and LED lighting manufacturing.

We offer the following range of services to answer questions and address issues related to all LED product component and materials at different manufacturing stages.

Our conventional lighting experts have years of experience troubleshooting and testing conventional lighting products, including discharge lamps, fluorescent lamps, UV lamps, and halogen lamps.

Eurofins EAG Laboratories also offers manufacturing consulting and advisory services including expert witness testimony, and intellectual property support.

We understand the need for first-to-market breakthrough technologies, and EAG can collaborate to provide results-driven solutions to the most complex of analytical investigations. Our experienced experts will work with your team to troubleshoot and choose the right material for your application or improve a manufacturing process.

Contact us today for your energy testing needs. Please complete the form below to have an EAG expert contact you.

Surface analysis lab techniques on α-Si thin film PV, microcrystalline Si, nanocrystalline Si, amorphous SiGe, & microcrystalline SiC

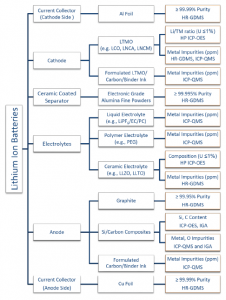

Chemical analysis techniques that can help to evaluate the composition of materials that are used for manufacturing Lithium Ion Batteries

Structural and Chemical Characterization of Li-ion Batteries help to understand why batteries fail leading to safer products and improvements.

Assessing the chemical state of various components of a battery, from the cathode to the current collectors, at different stages of cycling, provides crucial insights into the electrochemical processes that occur during battery operation.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.