Scanning Electron Microscopy Cathodoluminescence (SEM-CL)

Home » Our Techniques » Imaging » SEM-CL

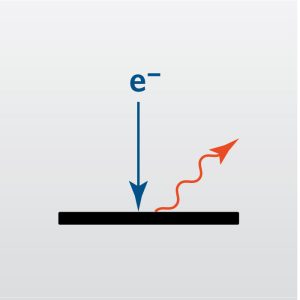

Cathodoluminescence (CL) is electromagnetic radiation, or light, ranging from visible (VIS) to near-infrared (NIR) created by the interaction of high-energy electrons (cathode rays) with a luminescent material. The light that is emitted carries very specific information about the optical and electronic properties of the sample.

Using a specialized Scanning Electron Microscope (SEM) that has visible light collection, corresponding sample structure (SE) and CL emission maps can be acquired simultaneously with sub-micrometer resolution. In some cases, the CL spatial resolution can be as good as 30-50 nm. CL mapping can be performed on both cross-sections (XS) or in plan-view (PV) to characterize a sample’s localized composition, doping, structure and defects, all with very high spatial resolutions.

Ideal Uses of SEM-CL

- Materials characterization – crystalline defects, bandgap determination, intra-bandgap trap states, composition, dopants

- Semiconductor failure analysis – defect localization within devices for deeper failure analysis (FA)

Strengths of Cathodoluminescence

- Provides highly localized information about materials optical and electronic properties

- Does not require electrical connections

Limitations of Cathodoluminescence

- Requires a luminescent material – semiconductors, polymers, insulators, metal photonic structures

- Smaller samples required, no full wafers larger than 1” dia – 3 mm height restriction

- Large amounts of topography, especially non-uniform surface roughness, can make CL collection and contrast interpretation more difficult. Smooth samples are preferred

- Thick (μms) metal contacts on the surface of a device must be removed before analysis. This can be often done by careful chemical etching or in specific regions by Focused Ion Beam (FIB)

- Localized dopant characterization is possible but requires careful choice of standards

SEM-CL Technical Specifications

- Signals Detected: Simultaneous Secondary Electrons (SE) and Cathodoluminescence (CL)

- Wavelengths Detected: 250-1500 nm

- Imaging/Mapping: Yes

- Lateral Resolution: Typically varies from 20-500 nm depending on SEM conditions and sample composition/topology

Related Resources

Would you like to learn more about using SEM-CL?

Contact us today for your Scanning Electron Microscopy Cathodoluminescence needs. Please complete the form below to have an EAG expert contact you.