Effects of Surface Roughness

The roughness of a surface and how it interacts with surrounding materials and elements can have a significant impact on material technology and its functionality.

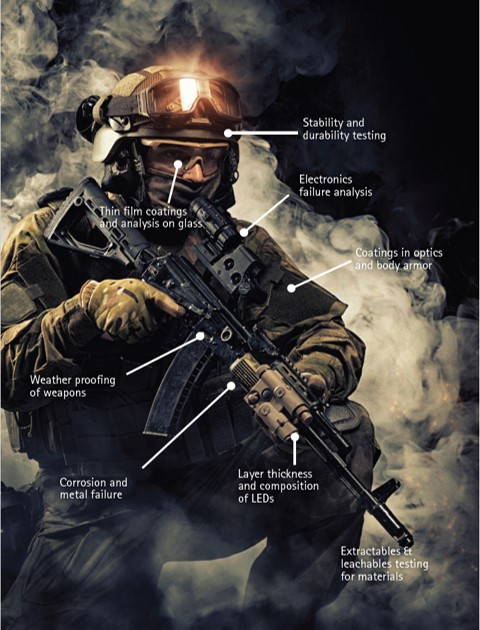

For over 50 years, EAG has performed defense materials testing to characterize high-performance materials and electronics used in combat and defense. EAG offers more specialized imaging and analytical expertise than any commercial contract laboratory in the world. We understand that stringent requirements for military electronics and materials can differ from commercial applications, ranging from operating temperatures to the full life cycle of components.

Our scientists and engineers have contributed to the development of some innovative armor, missiles and munitions through defense materials testing. EAG has a broad set of expertise and equipment to test, qualify, and analyze electronics. We are approved by the Defense Logistics Agency (DLA) to perform testing according to MIL-STD-750 and MIL-STD-883 in our Syracuse, NY laboratory, and our certifications also include ISO 9001:2015, ISO 17025, DSCC. Our US facilities are ITAR- and EAR-compliant and registered with the DDTC for defense-related articles and services.

How do you design for the world’s least-hospitable environments and, at the same time, ensure safety, speed and precision?

Turn to EAG. WE KNOW HOW.

EAG is a highly technical, skilled, and secure laboratory that offers a comprehensive suite of services to evaluate high-performance materials and electronics, meeting the industry’s exacting standards for tight controls of material properties, composition, and chemistry. Here are just a few ways we can help:

EAG can perform failure analysis on both integrated circuits and devices. Services range from Level 1 non-destructive examination to Level 3 fault isolation and root cause identification and characterization.

EAG provides internal gas and water vapor analysis in microelectronic components. We support MIL-STD-883, Method 1018 and MIL-STD-750, Method 10180 and can detect masses up to 140 AMU.

We can determine trace elemental impurities in ingots, manufactured parts, and the raw metal powders that go into nickel base superalloys, titanium alloys, cobalt alloys and other custom or specialized alloys.

Our scientists can provide deep insights into advanced materials, including metals and alloys, ceramics, coatings, plastics and polymers, composites, and porous materials.

EAG provides full structural characterization of CMC materials including chemical composition, impurities, microstructure, and interface chemistry of reinforcement fibers such as SiC, SiCN and carbon fibers.

We offer depth profiling and full chemical survey characterizations of many engineering coatings with a wide range of applications including optical, anti-reflective, environmental barrier, energy conversion, and corrosion resistance.

Our team offers the engineering expertise to design, develop, test, analyze, and debug the most innovative products using ATE, system-level testing, reliability and IC-level failure analysis.

Our sister company, Eurofins E&E, can evaluate components for use in extreme electromagnetic & environmental conditions to identify design flaws and bring equipment from development to production.

We offer monitoring of trace and ultra-trace level concentrations in raw materials using our techniques.

EAG is DLA (Defense Logistics Agency) certified for various MIL-STD testing requirements on materials used in aerospace, commercial, military and government applications.

We offer system-level testing for reliability and failure analysis of component and modules, including selection of tester platform, hardware, and fixture design, as well as ATE test programs in both development and production.

EAG performs failure analysis investigations of fractures to determine the mechanism and characteristics of the fracture, such as: fatigue, slow crack growth mechanisms, brittle and ductile overload, stress, corrosion, oxidation, and hydrogen embrittlement.

We can determine if any materials or equipment exposed directly to the skin contain any chemicals that are skin sensitizers with the potential to cause toxic or allergenic reactions.

Inspection of raw materials during key phases of manufacturing can aid in the identification and elimination of unwanted impurities in final products.

We are approved by the Defense Logistics Agency (DLA) to perform defense materials testing according to many MIL standards. Please add the MIL-STD in your request that you are interested in as we have experience with most including MIL-STD-167-1, MIL-STD-202, MIL-STD- 276, MIL-STD-461, MIL-STD-464, MIL-STD-704, MIL-STD-750, MIL-STD-810, MIL-STD-883, MIL-STD-1275, MIL-STD-1344, MIL-STD-1399, MIL-STD-1580, MIL-STD-1678-3 (3308), MIL-S-901, MIL-C-83522, MIL-DTL-83526, MIL-E-5400, MIL-PRF-24623, MIL-PRF-28800, MIL-PRF-28876, MIL-PRF-29504, MIL-PRF-49291, MIL-PRF-85045, Mil-HDBK-217, and MIL-I-24728. We have also tested to Special NASA DoD standards, and SSQ-25000.

Download the Aerospace and Defense Brochure Today!

Contact us today for your defense materials testing needs. Please complete the form below to have an EAG expert contact you.

The roughness of a surface and how it interacts with surrounding materials and elements can have a significant impact on material technology and its functionality.

XRF is a non-destructive technique that is used to quantify the elemental composition of materials.

17th November 2022

EAG has been approved as a suitable commercial laboratory to provide MIL-STD 883/750 Test Method 1018 Internal Water Vapor Content Testing for hermetically sealed electronic devices.

Aerospace Materials Testing for Tunnel Junction Solar Cells Science has opened many doors in its advancement over the centuries.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.