Amorphous vs. Crystalline Materials

Solids fall under two main categories: amorphous and crystalline. These two types of solids have different properties that may be more beneficial for certain products or applications.

EAG has provided aerospace materials testing services for over 50 years. We have partnered with aerospace customers to reduce weight and improve fuel efficiency by utilizing composite materials, as well as complied with the stringent requirements for military electronics whilst maintaining IP security and ITAR registration.

Eurofins EAG Laboratories (EAG) has been approved as a suitable commercial laboratory to provide MIL-STD 883/750 Test Method 1018 Internal Water Vapor Content Testing for hermetically sealed electronic devices at its Syracuse, NY laboratory. This testing is mandatory for hermetic microelectronic devices routinely used in space, defense, and medical applications.

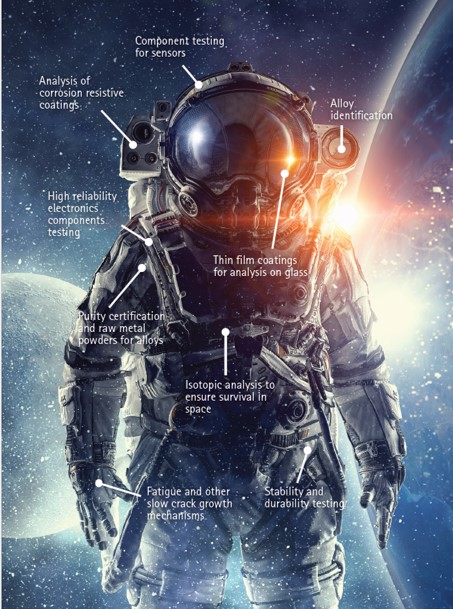

The next generation of lighter and stronger aerospace materials presents challenges of controlling purity and reliability. Using advanced analytical tools and proven methodologies, EAG Laboratories can support all aerospace materials testing from R&D to failure analysis. Our scientists and engineers are experts at translating scientific questions into novel study designs and test systems and have applied advanced analytical methodologies to answer complex engineering and manufacturing questions. We have solved complex failures of components such as aircraft fuselage, landing gears, gears and bearings, high pressure hydraulic hoses and fuel lines, turbine engines (compressor & hot section components), turbine and compressor blades, propellers, hydraulic system/fuel lines, LVDT and temperature sensors and more.

Turn to EAG. WE KNOW HOW.

EAG offers a comprehensive suite of materials testing services for the aerospace industry, meeting the industry’s exacting standards for tight controls of material properties, composition and chemistry. EAG is a certified partner (ISO 9001:2015, ISO 17025, DSCC, ITAR compliant, MIL standards compliant) and offers services to innovate new high-performance materials, test the reliability of aerospace electronic systems and investigate structural and metallurgical failures of aircraft. Here are just a few ways we can help:

EAG provides internal gas and water vapor analysis in microelectronic components. We support MIL-STD-883, Method 1018 and MIL-STD-750, Method 10180 and can detect masses up to 140 AMU.

We can determine trace elemental impurities in ingots, manufactured parts, and the raw metal powders that go into nickel base superalloys, titanium alloys, cobalt alloys and other custom or specialized alloys.

EAG is DLA (Defense Logistics Agency) certified for various MIL-STD testing requirements on materials used in aerospace, commercial, military and government applications.

We offer depth profiling and full chemical survey characterizations of many engineering coatings with a wide range of applications including optical, anti-reflective, environmental barrier, energy conversion, and corrosion resistance.

EAG can perform failure analysis on both integrated circuits and devices. Services range from Level 1 non-destructive examination to Level 3 fault isolation and root cause identification and characterization.

EAG provides full structural characterization of CMC materials including chemical composition, impurities, microstructure, and interface chemistry of reinforcement fibers such as SiC, SiCN and carbon fibers.

Our scientists can provide deep insights into advanced materials, including metals and alloys, ceramics, coatings, plastics and polymers, composites, and porous materials.

EAG performs failure analysis investigations of fractures to determine the mechanism and characteristics of the fracture, such as: fatigue, slow crack growth mechanisms, brittle and ductile overload, stress, corrosion, oxidation and hydrogen embrittlement.

We can determine if any materials or equipment exposed directly to the skin contain any chemicals that are skin sensitizers with the potential to cause toxic or allergenic reactions.

We offer monitoring of trace and ultra-trace level concentrations in raw materials using our techniques.

We offer system-level testing for reliability and failure analysis of component and modules, including selection of tester platform, hardware, and fixture design, as well as ATE test programs in both development and production.

Our sister company, Eurofins E&E, can evaluate components for use in extreme electromagnetic & environmental conditions to identify design flaws and bring equipment from development to production.

Eurofins EAG Laboratories also offers manufacturing consulting and advisory services including expert witness testimony, and intellectual property support.

Download the Aerospace and Defense Brochure Today!

Contact us today for your aerospace materials testing needs. Please complete the form below to have an EAG expert contact you.

Solids fall under two main categories: amorphous and crystalline. These two types of solids have different properties that may be more beneficial for certain products or applications.

RBS is the one technique where we can really say that the composition and concentration are accurately determined for thin films.

17th November 2022

EAG has been approved as a suitable commercial laboratory to provide MIL-STD 883/750 Test Method 1018 Internal Water Vapor Content Testing for hermetically sealed electronic devices.

PFIB differs from traditional FIB in that it uses various gases such as Xe, Ar, oxygen or nitrogen to generate a plasma that is used to remove material from a sample.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.