Meeting Material Purity Requirements with GDMS

Unwanted chemical impurities can be problematic. GDMS is a powerful full survey analysis tool for chemical purity evaluations.

Home » Residual Gas Analysis for Hermetically Sealed Devices

There are a lot of components that make up finished hermetically sealed devices. These components could be placed into finished products such as an instrument, machine, rocket, analyzer, or person’s body. Due to the different harsh environments that these finished devices could possibly encounter, it is important for the engineers of these components to ensure that they are impenetrable – or rather hermetically sealed. To be hermetically sealed essentially means to be airtight so that nothing can come in or get out (i.e., gas, moisture, liquid, etc.). it is impervious to external influence. If the part isn’t hermetically sealed, damaged, or defective seals can allow an ingress of gas inside, which can result in an unwanted chemical reaction that can ultimately lead to product failure.

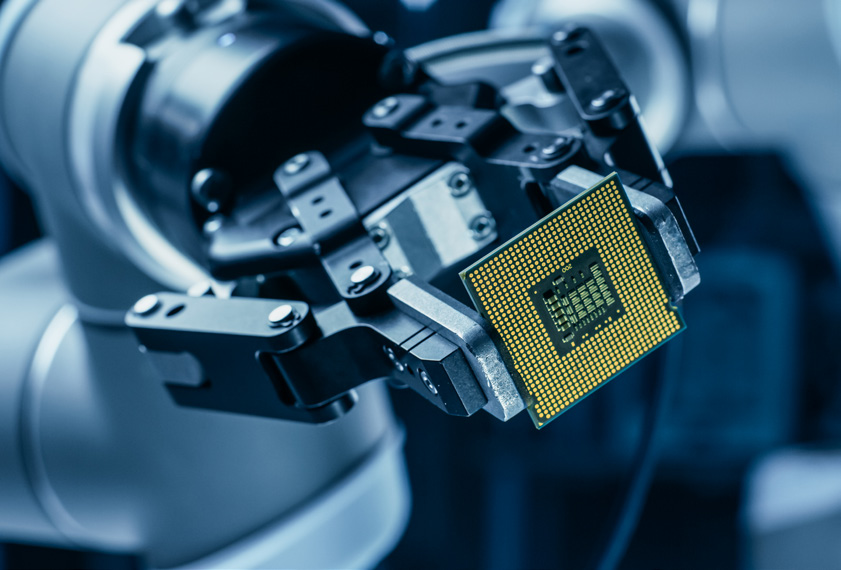

The finished devices that these components help build can be widely found in industries like aerospace and defense, implantable medical electronics, semiconductor, and automotive. Some examples of

hermetically sealed devices include microcircuits, semiconductors, heart pacemakers, cochlear implants, spinal stimulators, computer chips, or high-reliability electronics that go into space. In some instances, these parts need to be able to withstand a wide range of temperatures (i.e., semiconductors) or vacuum pressure (i.e., materials used in space).

To determine the efficacy of these devices there are two types of tests that engineers and scientists can run: a reliability test called Leak Testing and Residual Gas Analysis (RGA).

Eurofins EAG Laboratories (EAG) provides both the Cumulative Helium Leak Detection (CHLD) technique as well as Residual Gas Analysis (RGA).

CHLD is different from the standard leak test as it allows scientists to see much tinier leak rates than a conventional leak detector. This leak testing technique combines the fine and gross leak tests into one single test. CHLD can also be applied to any hermetically sealed device which contains Nitrogen, Helium, Argon, Krypton, Xenon, etc., or any device that can be “bombed” with Helium. The test involves taking parts and pressurizing them with helium and consequently measuring the leakage of helium from the leaking device. The goal is to have as little of a leak as possible. For hybrids/microcircuits MIL-STD-883 Test Method 1014 is typically used, and MIL-STD-750 Test Method 1071 is used for discrete semiconductor devices. These methods are non-destructive where the samples can be reused multiple times.

Residual Gas Analysis (RGA), also referred to as internal vapor analysis (IVA), is a technique used to test the internal gas composition of an electronic device with an emphasis on moisture content. An electronic device, such as a semiconductor, microelectronic, heart pacemaker, or cochlear implant can be fixtured to the RGA instrument. This testing technique is a gold standard of reliability testing for military and aerospace industries following MIL-STD 883 TM 1018. There are only 2 companies in the United States that are certified by the US Defense Logistics Agency (DLA) to perform this test and EAG holds the distinction of being one of the commercial testing services in the world able to perform this analysis.

RGA allows EAG Scientists to see the gas mixture that occurs inside the part. This will help determine if the issue is with something that was placed in the part, if the

moisture is something you want in the part, or if any chemical change happened in your part that you didn’t anticipate. This technique also provides manufacturers an indication of how long their part will last based on the moisture content that is found. Unlike CHLD, this is a one-time analysis as it is destructive, and the sample can only be used one time.

Contact EAG today to learn how we can be your partner for gas analysis of hermetically sealed devices. Working with EAG will bring breadth and depth of testing methodologies and experience, worldwide testing capabilities, consulting experience, and the highest level of customer confidentiality. EAG is the One-stop-shop for all testing and analytical needs.

Unwanted chemical impurities can be problematic. GDMS is a powerful full survey analysis tool for chemical purity evaluations.

EAG scientists are leaders in the lithium-ion batteries recycling arena. EAG is a valuable resource in understanding these materials.

High Depth Resolution Analysis will play a very important role in the electronic device industry as devices become smaller and smaller.

In this webinar we introduce Plasma Focused Ion Beam (P-FIB) which is a instrument that combines a SEM with a plasma-based FIB.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.