FIB Circuit Edit Webinar

In this webinar we introduce FIB Circuit Edit which allows the cutting of connections and placement of new lines in a semiconductor die

Home » Cathodoluminescence Illuminates the SEM with New Capabilities

In our blog, A Picture is Worth a Thousand Words, we discussed three of our high-resolution imaging techniques, TEM, STEM and AC-STEM. What we didn’t touch on is one of the most widely used analytical tools, Scanning Electron Microscopy (SEM). SEM is a great first-look in cases where optical microscopy can’t provide sufficient image resolution or high enough magnification. It can provide detailed surface topography in applications such as failure analysis, dimensional analysis, process characterization, reverse engineering and particle identification.

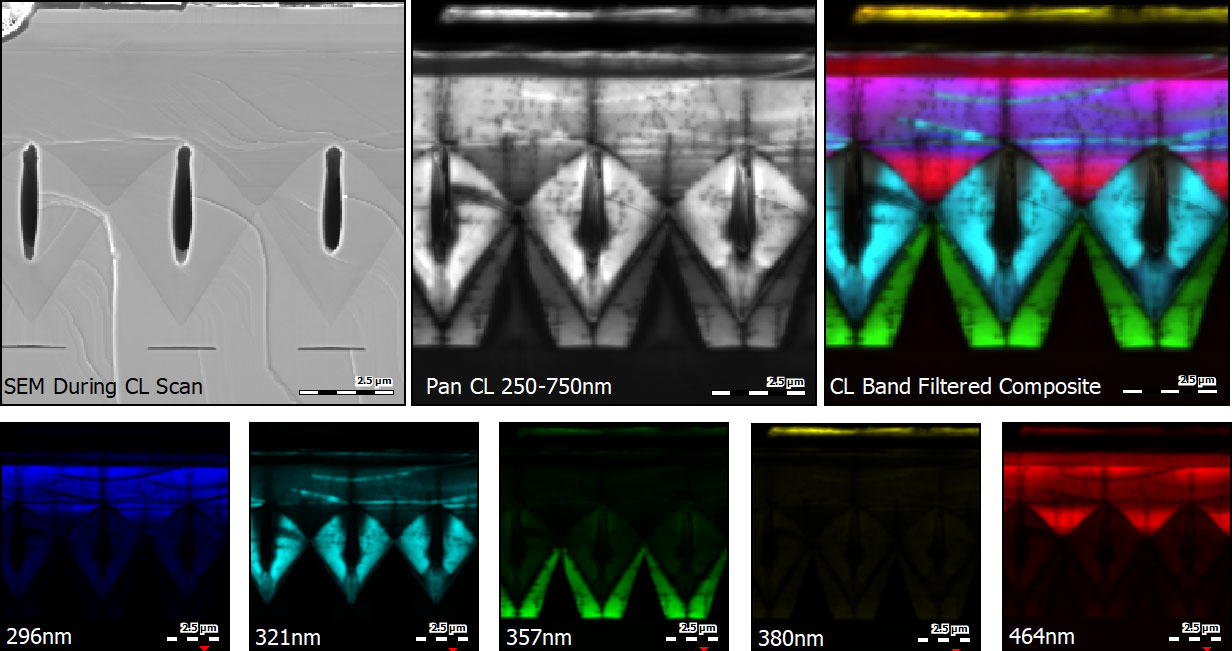

Using a specially designed instrument from Attolight of Switzerland (www.attolight.com), we provide SEM-Cathodoluminescence (SEM-CL) services for a wide variety of luminescent materials and devices. This technique allows for the inspection of optical properties with sub-um spatial resolutions combined with SEM imaging having 3-5nm spatial resolution. While this tool operates in essentially the same manner as a conventional SEM, it has the additional capability of detecting and quantifying the visible to near infrared light (275nm-1400nm) that is emitted from a sample during scanning.

This collected light is put through a sensitive spectrometer, allowing for a complete spectrum to be captured at each pixel (Hyperspectral Imaging) during the scan. Having a complete spectrum at each pixel allows for a wide variety of post-acquisition analyses including wavelength specific mapping as shown in the Figure above of a cleaved FACELO AlGaN laser structure on GaN (courtesy of Adroit – www.adroitmaterials.com). The different wavelengths of light are shown as different colors representing the various compositions of the material with very high sensitivity (better than EDS). This sensitivity is not only good for matrix level composition discrimination, but also for understanding dopant level constituents and their effects on the optical properties (down to 1e16 for Si in GaN). Here the yellow (380nm) shows the Donor Acceptor Pair (DAP) luminescence due to Mg doping in p-GaN region, and the green (357nm) shows changes in the carrier concentration in the n-GaN likely due to differences in the Si and Oxygen content.

SEM-CL analysis is typically used for direct bandgap semiconductors, primarily investigating GaN, InP and GaAs materials, but it can be applied to any type of sample that emits light under electron irradiation. It can help determine differences in composition with III-V materials and examine dopant level constituents. In addition to composition and structural information that the standard SEM offers, it provides insights on electro-optical properties and localization of crystal defects that are difficult to ascertain using any other methods.

The information provided by CL analysis can help guide our clients to modify their processes and improve the performance of their optoelectronic devices, such as lasers and LEDs.

At Eurofins EAG, we are your trusted partner in advanced microscopy analysis. We are one of the few commercial labs with the Attolight tool, offering SEM-CL services. With our years of experience and vast array of complementary analytical techniques, we can help determine the best suited techniques for your project.

Contact us today to learn how we can help you on your next project.

In this webinar we introduce FIB Circuit Edit which allows the cutting of connections and placement of new lines in a semiconductor die

In this webinar we introduce full Survey Chemical Analysis of Materials Used in Energy Storage Devices such as lithium ion batteries

EAG Laboratories pursues quality in all aspects of our work for customers. ISO certifications and ongoing audits serves many market sectors.

In this webinar we introduce Residual Gas Analysis (RGA), Evolved Gas Analysis (EGA), and Cumulative Helium Leak Detection (CHLD)

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.