Advances with Gallium Oxide

Gallium oxide has the potential to replace or substitute gallium nitride for power conversion in electric trains and vehicles.

Home » GDMS

Gallium oxide has the potential to replace or substitute gallium nitride for power conversion in electric trains and vehicles.

Battery materials characterization services includes analysis of raw materials, surface chemistry, composition, morphology and uniformity

One way to combat rising fuel costs in the aerospace industry and improve efficiency is to use new advanced materials such as Ceramic Matrix Composites (CMCs).

Ceramic matrix composites for aerospace materials must be of the highest purity. EAG presents FF-GDMS technique for robust chemical analysis.

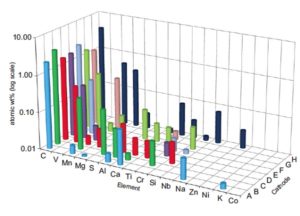

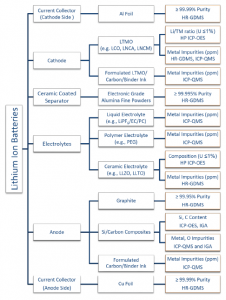

Chemical analysis techniques that can help to evaluate the composition of materials that are used for manufacturing Lithium Ion Batteries

High resolution GDMS is recognized as one of the most versatile direct sampling techniques for survey chemical analysis of solids.

EAG Scientists presented new research about the analysis of hard rock lithium ore at Nordic Conference on Plasma Spectrochemistry in Loen, Norway.

Photovoltaic Element Determinations by GDMS is ideally suited for trace element monitoring of PV grade CdTe/CdS materials.

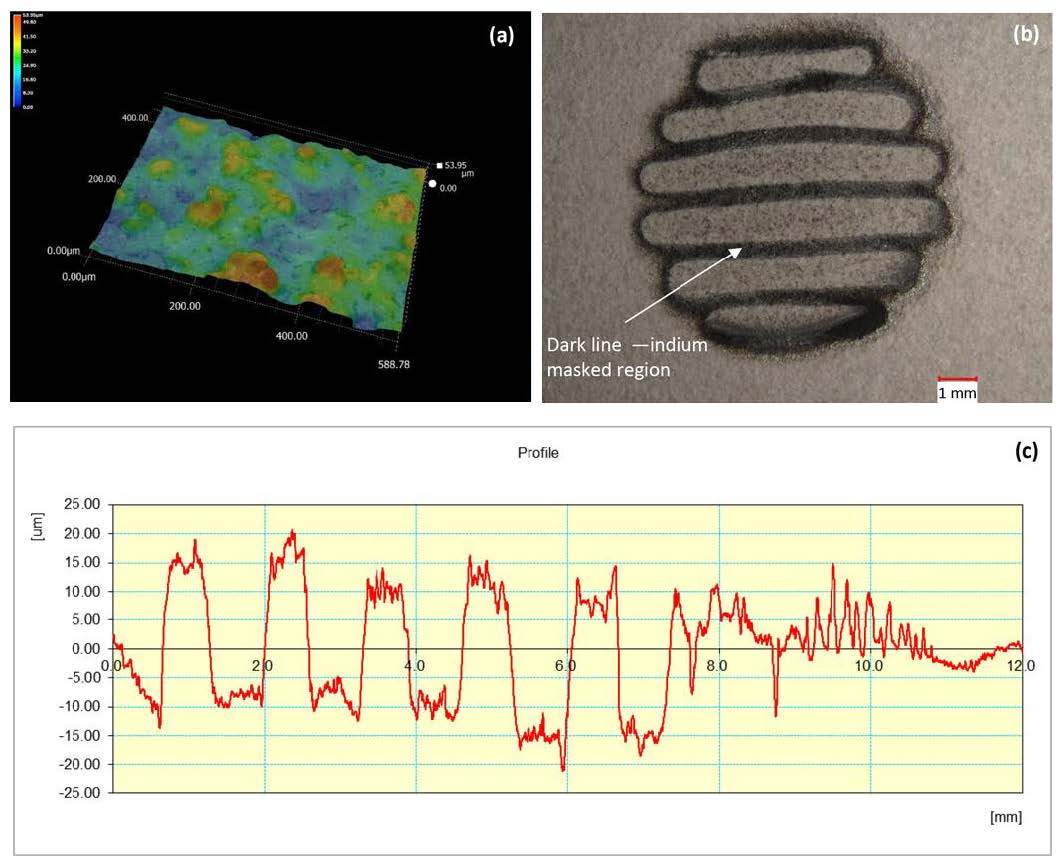

EAG Scientists utilize GDMS analysis to perform Elemental Depth Profiling for chemical purity evaluations for aerospace & defense.

In the full webinar we will focus on full survey chemical analysis using solid sampling high resolution GDMS.

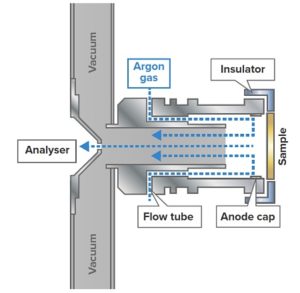

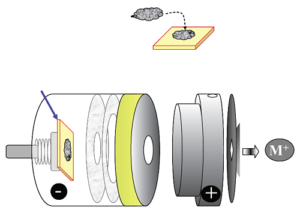

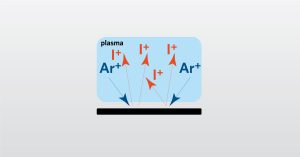

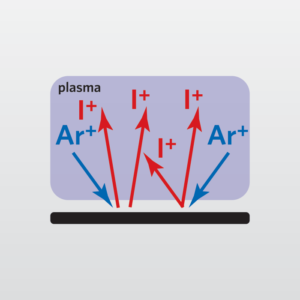

Glow discharge mass spectrometry (GDMS) is a robust analytical technique for direct determinations of elemental compositions of samples.

Your trusted partner in high purity raw materials testing and analytical services

Battery characterization improves lithium-ion battery safety and performance using techniques such as SEM, TEM, XPS, GDMS, FTIR, ICP-OES, Raman and failure analysis

EAG scientists are leaders in the lithium-ion batteries recycling arena. EAG is a valuable resource in understanding these materials.

Eurofins EAG Laboratories stands ready to assist in the analysis of lithium-ion batteries from the raw material supply chain through to the finished product and eventual recycling.

Unwanted chemical impurities can be problematic. GDMS is a powerful full survey analysis tool for chemical purity evaluations.

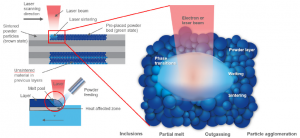

Additive manufacturing produces parts with geometric complexity, material composition gradient control, and lightweight structure design.

Glow discharge mass spectrometry (GDMS) relies on relative sensitivity factors (RSFs) in order to convert ion beam ratios of elements into mass fractions.

The term ‘rare earth elements’ (REEs) is a misnomer and better refers to the relatively rare ores REEs are extracted from; rare earth elements are all around us!

Silicon carbide is increasingly considered a potential replacement for traditional silicon semiconductors due to its superior properties.

Structural and Chemical Characterization of Li-ion Batteries help to understand why batteries fail leading to safer products and improvements.

Superalloys, combine two ore more elements of which one is Ni, Co, or Fe, and provide strength, toughness, and durability at high temps.

Supplier verification can be critical to the long-term success of your product and business. At Eurofins EAG, our technical experts have many years of experience working with battery materials. We are your battery partner to bring your product to market faster and more efficiently.

Graphite is and has been a ubiquitous mineral in our lives, from pencil “lead” and water filters to ancient markings on pottery.

EAG has more than 20 years of experience in purity certification and trace elemental analysis of titanium and alloys following ASTM Test Methods.

In this webinar we introduce Trace Analysis of Advanced Materials by Direct Solid-Sampling and Solution-Based Techniques

Lithium-ion batteries provide high energy density mobile power but come with three challenges: performance, safety and battery life.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.