A Solution for Sensitive Materials – Cryo FIB

Cryo FIB uses a cold sample stage that can be controlled to -135°C making it it more suitable for temperature sensitive materials.

Home » Metals

Cryo FIB uses a cold sample stage that can be controlled to -135°C making it it more suitable for temperature sensitive materials.

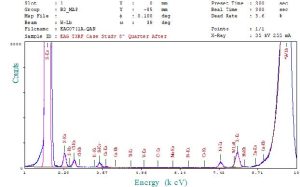

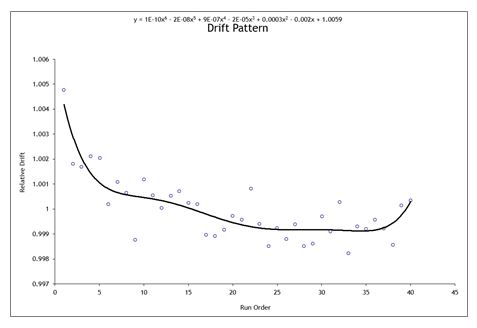

Wavelength Dispersive X-Ray Fluorescence Spectroscopy (WDXRF) is an ideal analytical tool for determining or verifying alloy compositions

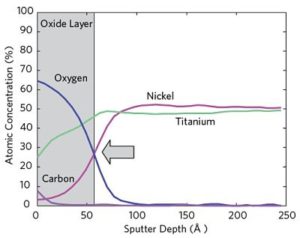

EAG evaluate corrosion and leaching of nickel-rich implanted medical devices including nitinol, stainless steel and MP35N.

Nickel biocompatibility assessments of intravascular stents from EAG includes evaluating corrosion, surfaces and nickel ion release testing.

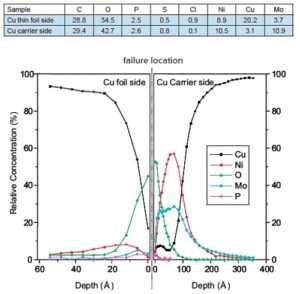

Laminate failure : Multi-layer laminate by analysis by XPS. Investigation details adhesive failure at a Ni2Mo-Cu interface due to monolayer contamination.

Surface Aluminum Characterization highlights advantages of using SurfaceSIMS.XP to determine contamination on processed Si wafers.

To identify and quantify contaminants, utilizing both TXRF and SurfaceSIMS.XP provides surface measurements on semiconductor surfaces.

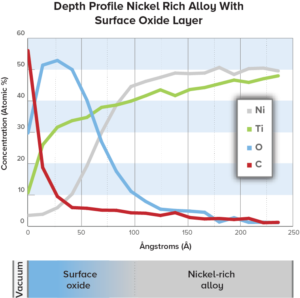

Medical device corrosion resistance optimized by using Auger depth profile & oxide layer thickness for device surface characterization.

This webinar covers FDA regulation of medical devices, the most commonly used test standards, and custom testing at Eurofins EAG Laboratories.

Thin films are widely used in many high-tech devices & consumer products. We discuss the processes used to measure the density of such films.

Evaluating Surface and Oxide Composition of Electropolished Stainless Steel for High-Purity Gas Distribution Systems

TGA with hyphenated technologies such as infrared (IR) and/or mass spectrometry (MS) is investigates the outgassing behavior of materials

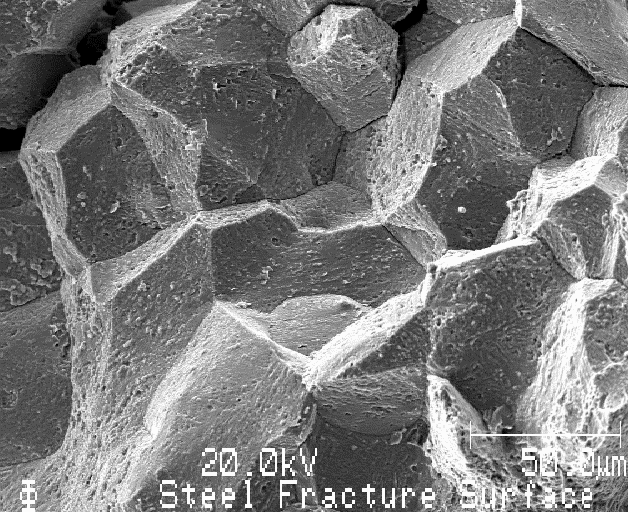

Failure analysis metals, nonmetals and composites for aircraft, aerospace, transportation, construction, consumer products, and electronics.

Failure Analysis and product improvement of metal components is a specialty at EAG Laboratories

Food packaging materials can be made with plastics, paper and board, glass, metal, wax, and printing inks. These packaging materials are directly and indirectly in contact with our food.

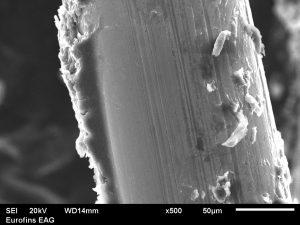

Characterization of metallurgical failures includes identifying segregation of elemental impurities to the surface of grain boundaries.

This paper describes identification of two unknown powders using Raman spectroscopy, combined with two X-ray techniques

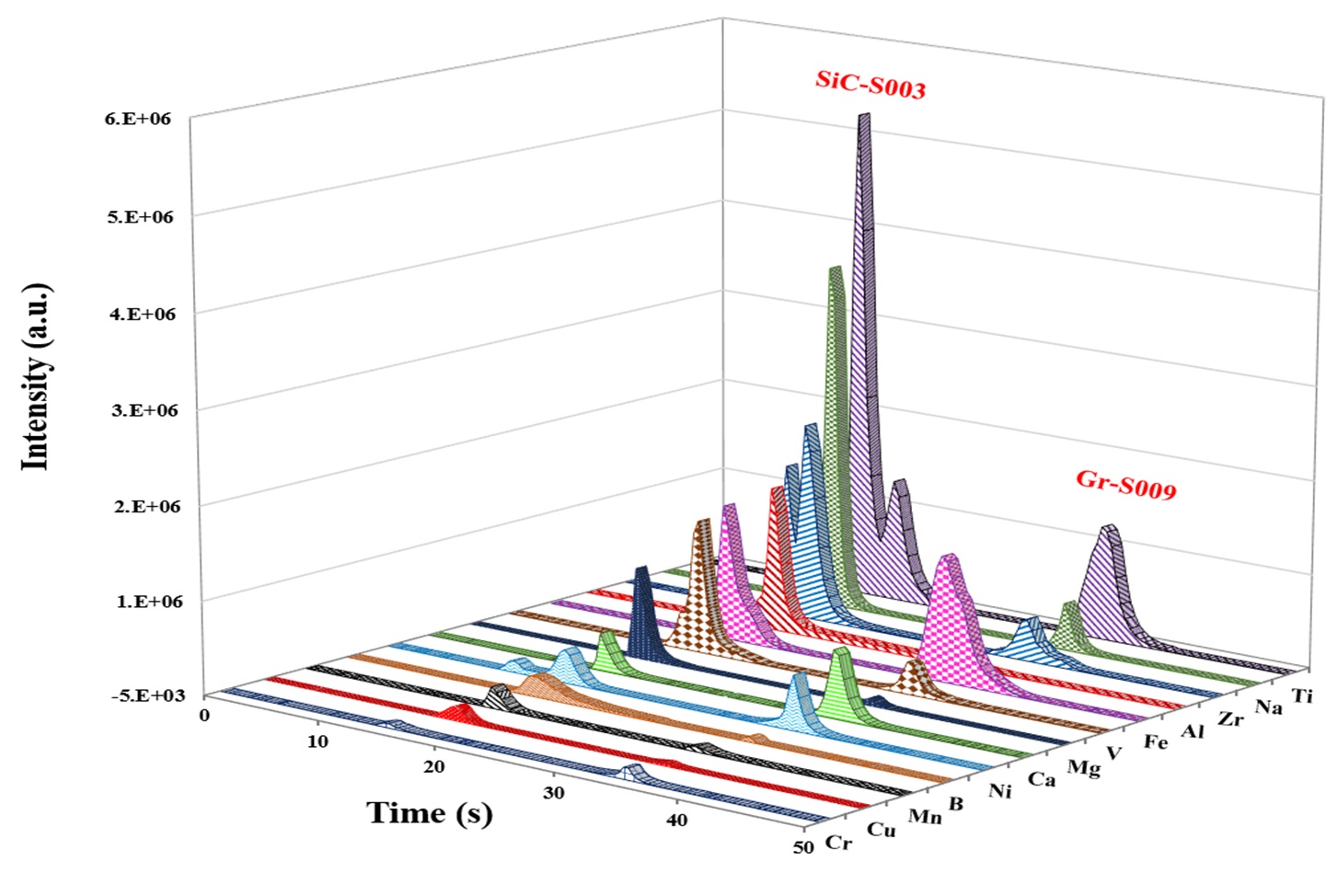

LA-ICP-MS is an analytical technique that uses direct micro-scale sampling to provide high precision elemental and stable isotope analyses of solid maters

Eurofins EAG Laboratories stands ready to assist in the analysis of lithium-ion batteries from the raw material supply chain through to the finished product and eventual recycling.

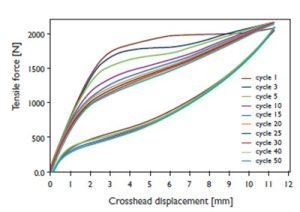

Mechanical testing incorporates the measurement of the material’s mechanical response to an applied force or displacement

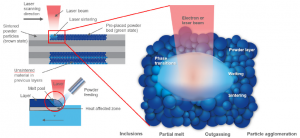

In this webinar we introduce Metal Based Additive Manufacturing Analysis to understand and evaluate many aspects of the metallurgy.

Metallurgical testing lab services from EAG Laboratories includes grain size analysis, Rockwell hardness and image analysis.

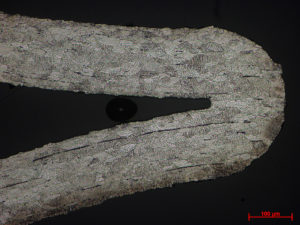

Additive manufacturing produces parts with geometric complexity, material composition gradient control, and lightweight structure design.

Complex oxides in energy storage, catalysis, sensor/actuation, optics, epitaxy substrates, electronics, bioceramics, structural ceramics

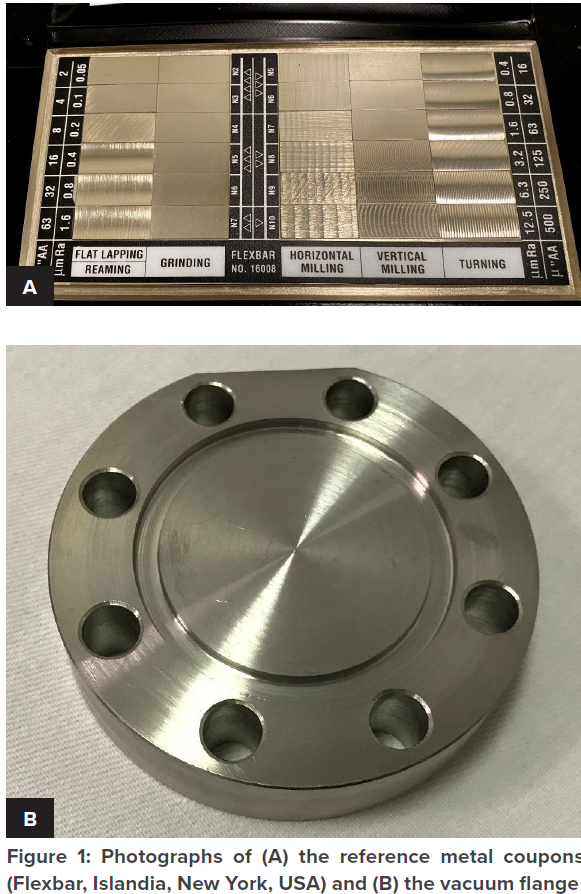

Characterizing surface topography is possible with a technique called Optical Profilometry (OP) also known as White Light Interferometry.

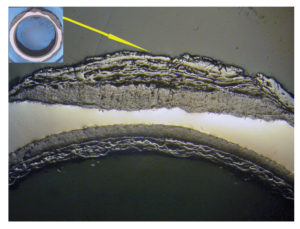

The contact lens market has expanded beyond its original goal of vision correction to include products with decorative qualities.

In this webinar we introduce Multiscale Assessment on the Quality of Metal Powder Feedstocks for Additive Manufacturing

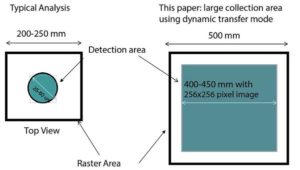

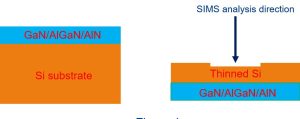

Impurities adversely affect performance of a CIGS solar cell, with varying concentrations – SIMS can help measure representative sampling.

SIMS detects very low concentrations of dopants and impurities. It has been used to study the diffusion of Al and Ga.

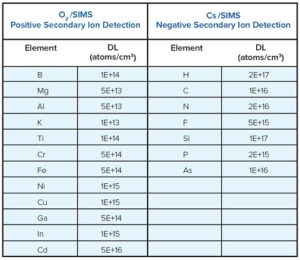

SIMS ZnO detection limits of selected elements under normal depth profiling conditions, showing overlay of SIMS profiles of arsenic implant

Auger Electron Spectroscopy (AES) is effective in determining the quality of passivation layers to prevent corrosion in medical devices.

In this webinar we introduce analytical techniques used by EAG for surface analysis – XPS, Auger and TOF-SIMS

EAG has more than 20 years of experience in purity certification and trace elemental analysis of titanium and alloys following ASTM Test Methods.

Electrothermal vaporization (ETV) coupled with ICP-OES is an exceptionally sensitive solid sampling technique for purity verifications.

ICP-MS is a multi-elemental bulk chemical analysis technique that can determine simultaneously up to 70 elements in a single sample.

When Metal Fails: How Metallurgy Helps Us Understand Bridge Collapses INTRODUCTION Bridges are marvels of human engineering. Many bridges are even famous landmarks. Despite their

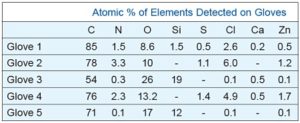

XPS Analysis of Disposable Gloves assesses materials exposed during product manufacturing to make sure contamination is not introduced.

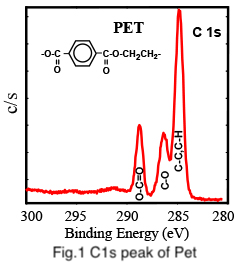

XPS (X-ray photoelectron spectroscopy) is capable of qualitative and quantitative analysis, and it can also determine chemical states.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.