AES Webinar

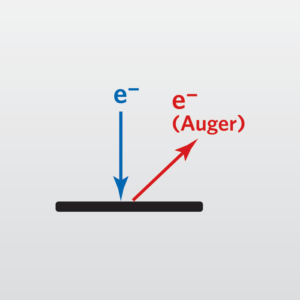

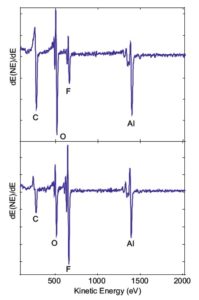

This webinar is an introduction to Auger Electron Spectroscopy. It will include the principles of the technique with examples.

Home » AES

This webinar is an introduction to Auger Electron Spectroscopy. It will include the principles of the technique with examples.

CIGS Thin Film PV performance reliability and uniformity as manufacturing is scaled up, can be optimized using materials characterization.

Surface chemistry affects multiple properties including adhesion, wettability, appearance and cleanliness. Auger, TOF-SIMS and XPS are often used to understand chemistry in the top few nanometers of a sample surface.

Auger Tutorial by EAG, in this instrumentation overview we present the history of Auger, along with details regarding analyzers and detectors

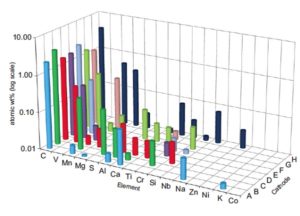

Battery materials characterization services includes analysis of raw materials, surface chemistry, composition, morphology and uniformity

Biomedical surface analysis looks at properties critical to medical and pharmaceutical products, and offer answers to difficult problems.

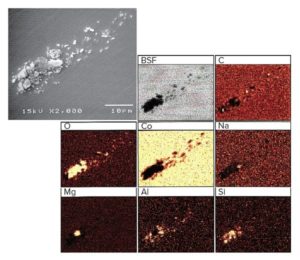

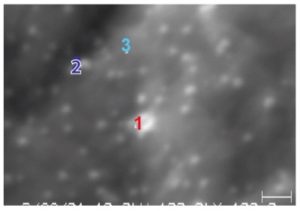

A discussion of EAG’s elemental characterization of defects and contamination on surfaces for failure analysis through EDS, SEM and AES.

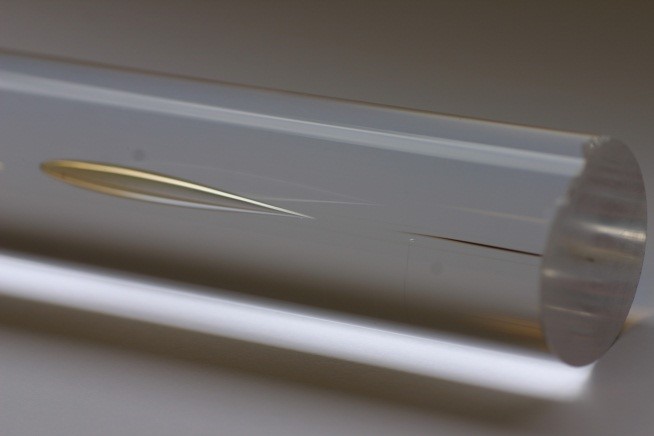

The chemical composition of all kinds of glass defects can be determined by SEM combined with EDS, XRF, Auger, and RGA.

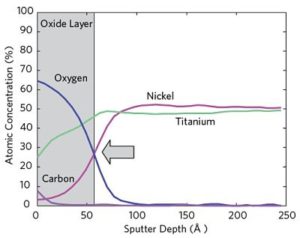

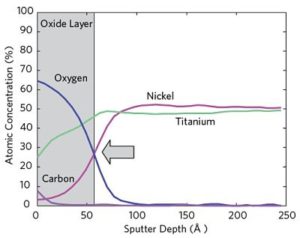

Medical device corrosion resistance optimized by using Auger depth profile & oxide layer thickness for device surface characterization.

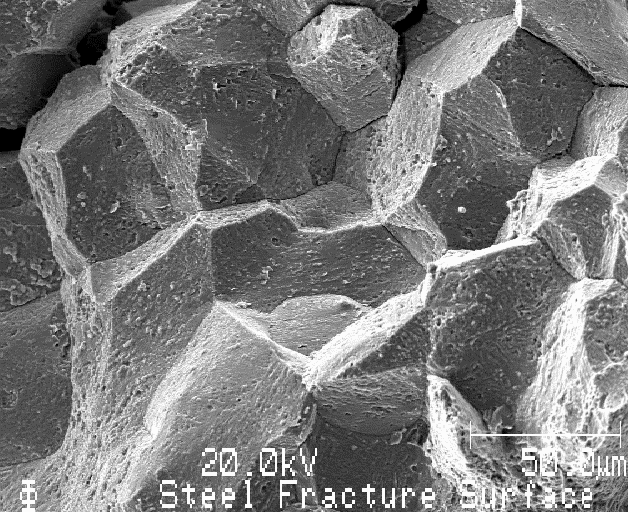

Characterization of metallurgical failures includes identifying segregation of elemental impurities to the surface of grain boundaries.

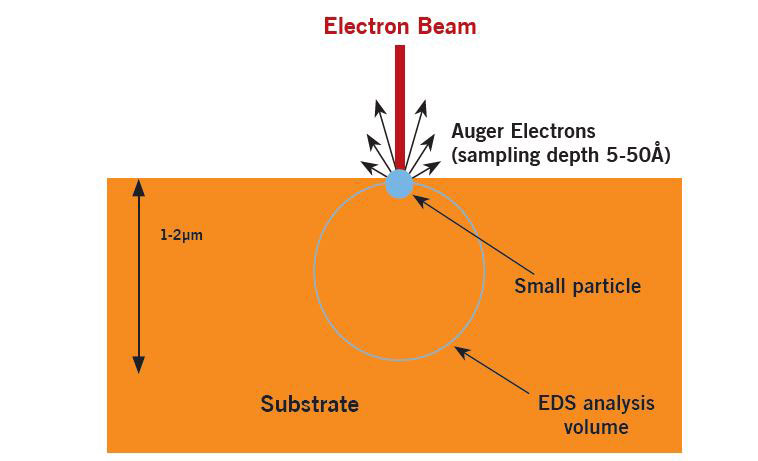

Auger (AES) spectra of small defects of various sizes shows excellent sensitivity is maintained down to a defect size of only 20nm.

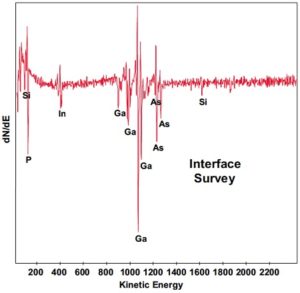

Auger Identification Interface Contamination is discussed regarding the elimination of contaminants for successful semiconductors.

LED characterization, from process control to failure analysis to construction analysis, EAG Laboratories supports your LED analysis needs.

Auger Electron Spectroscopy applied to electronic circuitry problems involving the integrity of wire or ball bonding to metallic bond pads.

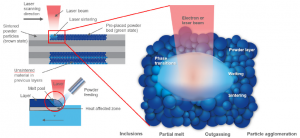

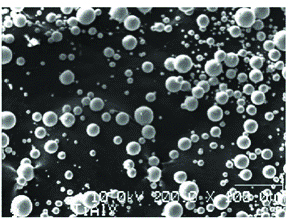

Additive manufacturing produces parts with geometric complexity, material composition gradient control, and lightweight structure design.

One of our surface analysis techniques, TOF-SIMS, can be used to characterize the surface coatings on screens and to compare the thickness of the coatings using depth profiles.

Particle analysis helps with black speck analysis, contamination identification, particulate analysis, identification of unknown materials.

Auger Electron Spectroscopy (AES) is effective in determining the quality of passivation layers to prevent corrosion in medical devices.

In this webinar we introduce analytical techniques used by EAG for surface analysis – XPS, Auger and TOF-SIMS

There is still so much to learn about batteries, including challenges such as energy density, cycle life, fast charge, and safety. In this blog, we’ll be focusing on energy density.

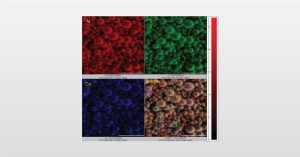

Both Auger Electron Spectroscopy (AES) and Energy Dispersive X-ray Spectroscopy (EDX / EDS) are used for elemental analysis.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.