Fracture Analysis of Metal Grain Boundary Segregation by Auger

Home » Fracture Analysis of Metal Grain Boundary Segregation by Auger

Characterization of metallurgical failures may include the need to identify segregation of elemental impurities to the surface of grain boundaries of the metal alloy. This surface segregation, which can be a layer of impurities thinner than 5nm or sub-micron precipitates, can result in brittleness of the material. The difficulty in characterizing this elemental segregation lies in maintaining the cleanliness of the fracture surface for subsequent analysis.

Breaking the metal alloy in atmosphere will contaminate the fracture surface, making positive identification of any segregates difficult to impossible. The alternative solution is to break the metal under high vacuum conditions (10 -10 torr) that will maintain a pristine fracture surface for an extended period of time and allow subsequent analysis of the exposed grain boundaries. This type of analysis is possible with Auger Electron Spectroscopy (AES).

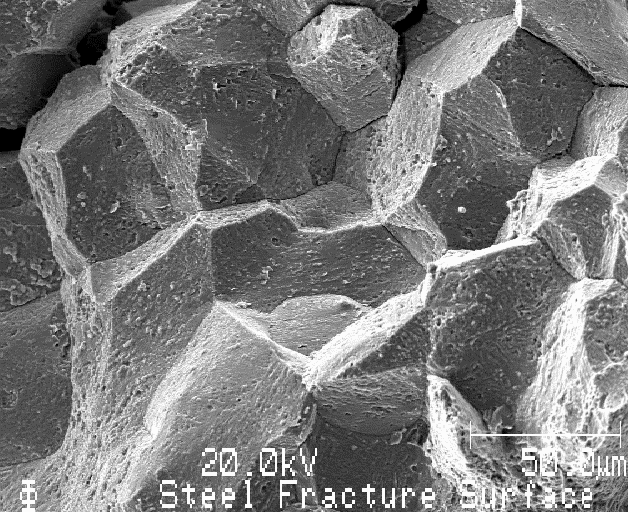

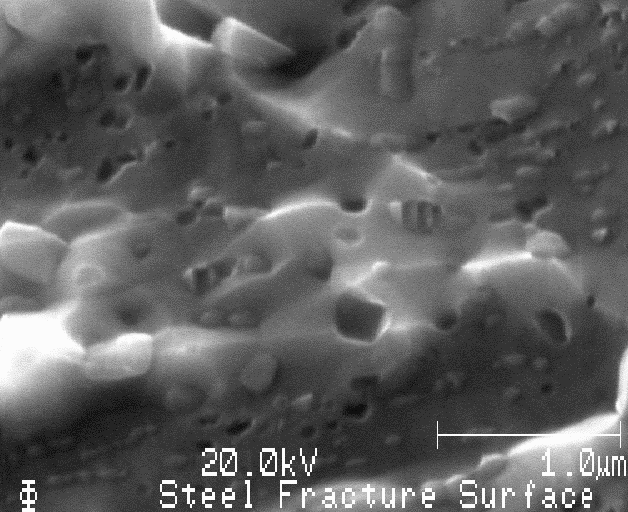

The sample analyzed is a forged low alloy steel sample that failed after years of service at high temperatures. Examination of the failure surface showed brittle intergranular failure. A section of the sample was machined to size for subsequent in-situ vacuum fracture and analysis in an AES instrument.

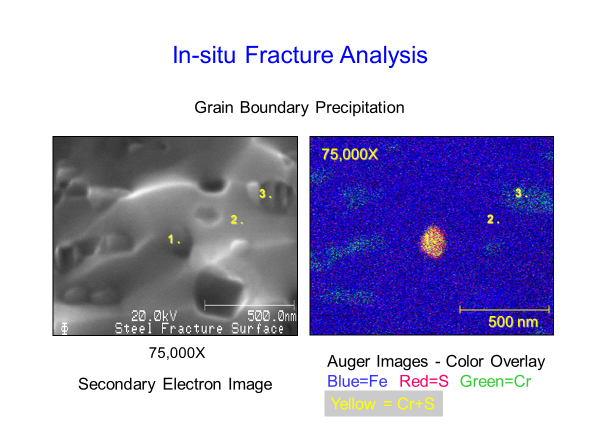

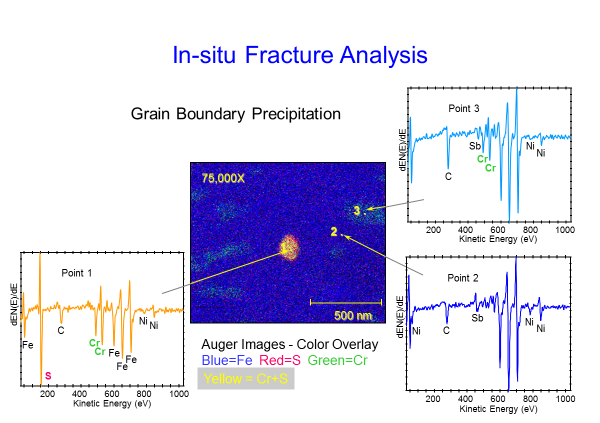

Grain boundaries were readily evident in the SEM images taken on the instrument. The area analyzed at 75,000X shows both inclusions and the adjacent exposed grain face. Elemental maps and survey scans show the nodules are identified as Cr-sulfide and Cr-carbide while the exposed grain face shows the presence of Sb. Antimony is a known embrittlement agent in alloy steels.

Analysis of grain boundaries in metal alloys can provide insight into the structural integrity of the material. If impurities are found at the grain faces, this may lead to embrittlement and failure of the product. Whenever investigation of metal process development or metal failure is needed, EAG’s AES instruments can provide valuable information.

Would you like to learn more about In-Situ Fracture Analysis?

Contact us today for your in-situ fracture analysis needs. Please complete the form below to have an EAG expert contact you.