Mechanical Testing

Home » Mechanical Testing

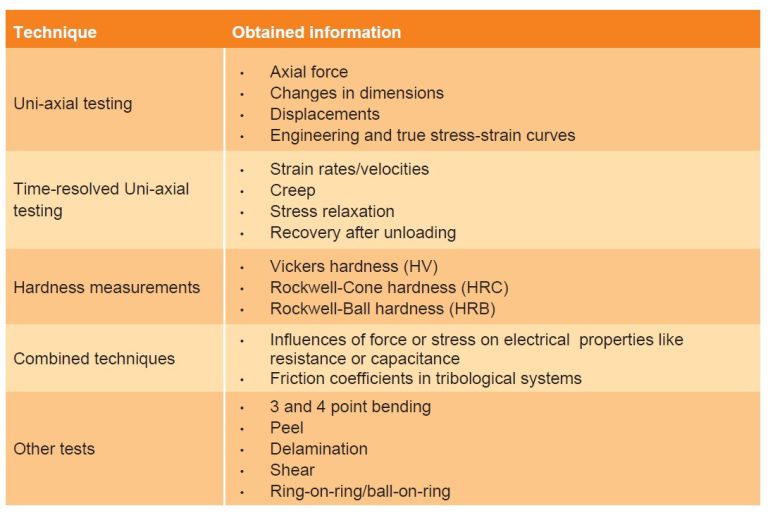

Mechanical testing incorporates the measurement of the material’s mechanical response to an applied force or displacement. Our large portfolio of testing facilities enables determination of many mechanical properties (Table 1, next page). Depending on the information required, dedicated tests can be performed. Numerous projects are supplied with mechanical data that are used as input for modeling activities, materials selection, problem solving, and virtual prototyping.

Applications

- Verification of mechanical properties of an ordered batch of material.

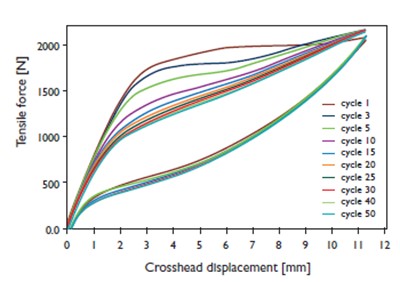

- Mechanical characterization of uncommon materials (like super alloys and membranes, see also Figure 1).

- Electrical resistance measurements of flexible displays or stretchable electronics.

- Compliance measurements of springs.

- Determination of the degree of hysteresis damping of polymeric and elastomeric foils.

- Determination of the fracture tough-ness of laminated polymeric foils for medical devices.

- Delamination studies of ICs and their compounds.

- Strength measurements of welds.

- Fracture path studies in adhesively bonded materials.

- Determination of the ratio of the adhesive fracture surface to cohesive fracture surface of an adhesive bond in a tensile test (after fracture).

- Edge quality determination of diced Si-wafers by 4-point bending.

- Calibration (or verification) of load cells.

- Generally, measurements of forces, dimensions, and displacements. If required, these parameters can be measured as a function of time.

Characteristics

Information:

- Mechanical properties.

Sample type:

- Solid materials and combinations of materials (metals, polymers, elastomers, ceramics, composites, bonds, welds), within temperature limits (-80ºC to +250ºC).

- Structures and assemblies within temperature, dimension, and mass limits.

Sample quantity:

- Dimensions in the order of cm or dm.

- Minimum layer thickness of 5 µm in cross-section for Vickers micro-hardness measurements.

Detection limits:

- Force measurements: N – 20 000 N.

- Calibrated force range: 0.4 N – 20 kN.

- Minimal (longitudinal and transversal) displacement: 1 µm (also contactless).

- Time-resolved measurements: 10 Hz.

- Vickers (micro-)hardness: 05 gf to 30 kgf.

Accuracy & Precision

- Dependent on technique and apparatus used.

Test standards

- The tests can be performed according to quality standards like ASTM, ISO, EN, DIN, NEN, BS, JIS, Philips (UN) and AFNOR.

- Custom-made tests.

Would you like to learn more about Mechanical Testing?

Contact us today for your mechanical testing needs. Please complete the form below to have an EAG expert contact you.