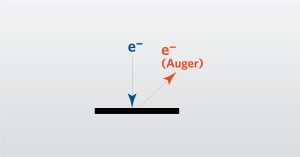

Ask the Experts: Materials Characterization of GaN Power Transistors

Demand for compound semiconductors has rapidly grown recently. During this live event we answered questions surrounding the Materials Characterization of GaN HEMT power transistors.