A Deep Dive into High Powered Electronics

High Powered Electronics are used in a wide suite of applications, from consumer electronics and electric vehicles to railways and power plants and even artificial intelligence.

Home » Understanding Lithium-Ion Batteries and Why They Fail

As consumers we consume products every day not knowing exactly how they’re made, how they function or how they’re powered. For consumer electronics (i.e., cell phones, laptops, implanted heart monitors, etc.) and the ever-growing electric vehicles (EV) market, Lithium-ion batteries provide lightweight and efficient power. While these batteries are great because they offer a higher energy density than lead-acid or nickel-metal hydride (NiMH) batteries, there are three critical issues with them that need to be addressed: performance, cycling lifetime and safety, all depending on “clean” manufacturing.1

If you watched the commercials for Superbowl LVI most of the auto advertisements were advertising for electric vehicles – the new evolution of how we get around is here. For EV applications, battery performance is of particular importance because the operating life and battery deterioration over time could hurt the market.

The EV range has improved over time but is still limited and charging stations are not always readily available. In addition, over time the battery performance degrades (for multiple reasons) despite needing to last for 8-10 years.

A few companies have been in the news headlines for issues and challenges related to their lithium-ion batteries. These incidents were dangerous and brought the safety concerns to a forefront. This further emphasizes the importance of designing batteries with the end product and usage in mind. With all the safety issues come legal concerns for manufacturers which amounts to immense business costs and loss of business opportunities due to product recalls, delay, and supply chain disruption. Lastly, quality inconsistencies, caused by impurities, are hard to control and lead to a lack of “clean” manufacturing.

EAG understands the challenges and needs within the market and has continuously accommodated the industry by developing better sampling and testing methods and updating instrument for sensitive detection of trace impurities which can cause issues in a battery. Unexpected and unaddressed contamination can have a dramatic impact on manufacturing processes; therefore, it is critical to make sure these unaddressed issues are understood and controlled quickly. EAG makes sure that impurities are controlled in spec which significantly reduces the possibility of fire explosion because of how clean the material is. In addition, doing a comprehensive Failure Analysis of a material helps manufacturers answer questions pertaining to the failure of their product.

Glow Discharge Mass Spectrometry (GDMS), Inductively Coupled Plasma Mass Spectrometry (ICP-MS), Inductively Coupled Plasma Optimal Emission Spectroscopy (ICP-OES), etc., are some of the techniques used to determine whether or not there was a composition change, if there is a contamination bulk level change, and overall where it went wrong.Proper characterization is important for improving lithium-ion battery performance and addressing safety concerns. EAG is a valuable resource and partner to the battery supply chain to help achieve clean and consistent manufacturing. We would love to work with you to discover your challenges related to Lithium-ion batteries. Contact us today to learn more about our capabilities with Lithium-ion batteries.

High Powered Electronics are used in a wide suite of applications, from consumer electronics and electric vehicles to railways and power plants and even artificial intelligence.

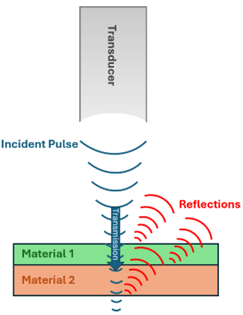

Complementary Techniques: X-Ray & SAM X-ray imaging is a great non-destructive technique that is used in many industries to help visualize internal construction. Scanning acoustic microscopy (SAM) is another non-destructive

Wednesday, May 14, 2025

This webinar will cover the chemical characterization of consumer products using extractable/leachable studies. Register to reserve your spot today!

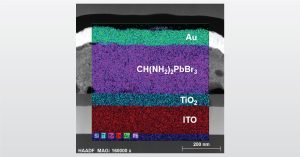

In the full webinar we will discuss Thin Film Analysis that looks at film composition, thickness, and uniformity.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.