Ask The Expert – All About SIMS Webinar

In the full webinar we answer pre-submitted questions from our audience about Secondary Ion Mass Spectrometry

Home » Elemental Depth Profiling Analysis for the Aerospace & Defense Industry

Do you ever wonder how airplanes are made to survive the different elements in the sky? Or, how a space craft can sustain such high heat during launch and then the extremely cold temperatures while in orbit? What is it that manufacturers of these aircrafts use in order to make sure their products are reliable in extreme temperatures? Among others, they achieve this using protective coatings. In aircraft engines, for instance, conversion coatings of airfoils have the function of protecting the base alloys (nickel-, iron-, and cobalt-based alloys) to prevent against corrosion at high operating temperatures. For manufacturers of these aircraft and their parts, it is critical to ensure that the materials will not fail. Here at Eurofins EAG Laboratories (EAG) we are skilled in the testing of these materials using Elemental Depth Profiling.

Elemental depth profiling is a chemical purity evaluation of a wide variety of solid samples such as multi-layered films or coatings on

metals and alloys, manufactured carbons or ceramics. It can evaluate the surface from sub-micron down to 100’s of microns depth and it can evaluate if the sample is protected against harsh environmental (i.e. oxygen, sulfur, chemical vapors, etc.) elements. Fast-flow is Glow Discharge Mass Spectrometry (GDMS) the technique most commonly used for depth profiling measurements on aerospace materials. GDMS is a high-resolution mass spectrometric technique, which is based on glow discharge atomization/ionization sources combined with sector-file mass analyzer. Depth specific distributions can be evaluated with very high sensitivity if measurements are conducted in flat sampling geometry. It is a technique that is capable of providing trace-level elemental quantification for a wide range of solid and powder materials.

Complementary techniques include Inductively Coupled Plasma Optical Emission (ICP-OES) or Mass Spectrometry (ICP-MS), X-ray Fluorescence (XRF), Instrumental Gas Analysis (IGA), and Secondary Ion Mass Spectrometry (SIMS). The ICP techniques are commonly solution based and require sample dissolution. XRF can be used as a survey technique that offers the advantages of high precision, higher spatial resolution, and being nondestructive; however, XRF has higher detection limits and spectral interferences that can limit sensitivities with some element combinations. SIMS has similar or better sensitivity than GDMS, but it requires very good reference materials. It is complementary to GDMS in that it can achieve excellent detection limits for atmospheric species (C, O, and H) for which GDMS has limitations. GDMS has greatly reduced matrix affects, however, SIMS has significantly better depth resolution. IGA is complementary to GDMS for atmospheric species (H, C, N, O and S).

EAG’s scientists are especially equipped to analyze samples directly using flat sampling – analyzing for one side of a sample that is constantly corroding. Measurements are then based on industry standards, such as ASTM, ISO Nadcap to ensure the highest level of reliability for our clients. GDMS has the ability to scan up to 75 elements with low sensitivity and can run solid inorganic materials. It’s a purity test that tests solid materials from different parts of the supply chain. Some strengths of this technique are that it can run a full survey of all stable isotopes (except H), has parts per billion sensitivity, limited matrix effects, linear calibration, and robustness.

EAG is the industry leader for Glow Discharge Mass Spectrometry (GDMS) analytical services with the largest number and variety of GDMS instruments installed. Our depth and breadth of experience and dedication to innovative analytical methods is unrivaled. The GDMS instruments consist of a balanced mix of low-pressure type and fast flow type instruments, allowing coverage for a great range of applications. EAG offers the best detection sensitivity along with accurate mass fraction determinations in bulk solids and thick coatings. Contact us today to discuss how we can assist you with your depth profiling needs.

In the full webinar we answer pre-submitted questions from our audience about Secondary Ion Mass Spectrometry

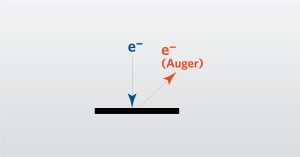

This webinar is an introduction to Auger Electron Spectroscopy. It will include the principles of the technique with examples.

In this webinar we will focus on Dynamic Secondary Ion Mass Spectrometry which used to investigate the elemental structure of materials.

In vitro biocompatibility testing is a powerful tool in the risk assessment of wearable devices. View our webinar to learn more!

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.