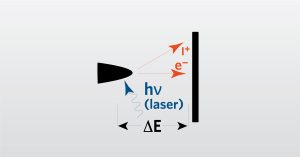

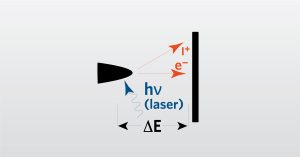

APT Webinar

In this webinar we introduce Atom Probe Tomography (APT) which is a technique that provides three-dimensional (3D) chemical and spatial maps.

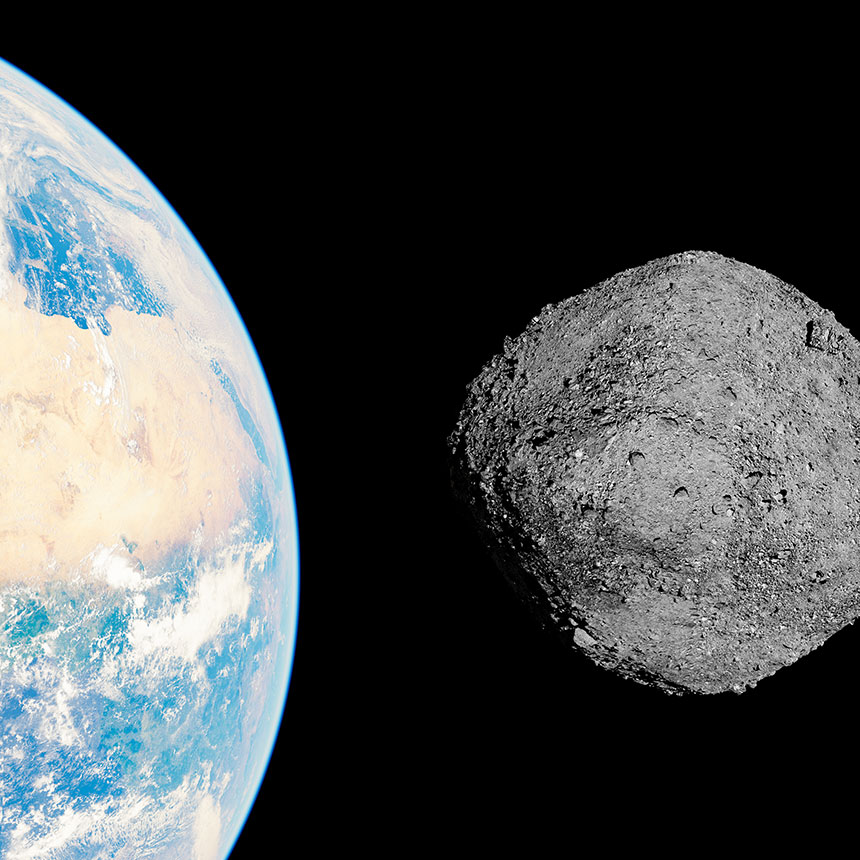

Home » A First Look at Bennu

I’m sure you’ve heard in recent news about the 4.5 billion year old asteroid, Bennu. Bennu was discovered by the Lincoln Near-Earth Asteroid Research (LINEAR) project back in 1999. NASA launched the OSIRIS-REx mission in September 2016 to collect and return samples of Bennu to Earth. Seven years later on September 24th, 2023, a capsule containing the asteroid sample returned and landed back on Earth.

Of course, the next question is… what’s in the sample? This is where materials analysis plays a major role. It’s cool to know that some of the analytical techniques available at EAG, such as scanning electron microscopy (SEM) and X-ray diffraction (XRD), are being used to analyze a sample from space! How awesome is that?

A recent article stated, “The quick-look research will utilize various instruments, including a scanning electron microscope (SEM), infrared measurements, and X-ray diffraction (XRD), to gain a better understanding of the sample. The SEM will offer a chemical and morphological analysis, while the infrared measurements should provide information on whether the sample contains hydrated

minerals and organic-rich particles. The X-ray diffraction is sensitive to the different minerals in a sample and will give an inventory of the minerals and perhaps an indication of their proportions.”1

At Eurofins EAG, our experts utilize SEM analysis to produce high resolution images as a great ‘first-look’ at a sample for various industries, such as semiconductors, compound semiconductors and batteries. SEM provides high-resolution and high-depth-of-field images of the sample surface and near-surface and is one of the most widely used analytical tools, due to the extremely detailed images it can quickly provide.

After the initial studies, it was discovered that the Bennu sample did contain carbon and water. Another article stated, “Within the first two weeks, scientists performed “quick-look” analyses of that initial material, collecting images from a scanning electron microscope, infrared measurements, X-ray diffraction, and chemical element analysis. X-ray computed tomography was also used to produce a 3D computer model of one of the particles, highlighting its diverse interior. This early glimpse provided the evidence of abundant carbon and water in the sample.2

Eurofins EAG uses XRD to provide information on phase identification, semi quantitative analysis and percent crystallinity. For years, we’ve used this analysis on all types of materials, including semiconductor thin films, ceramics, metals,

carbon for battery anodes, pharmaceuticals and much more. Another great thing about the technique is that it is nondestructive, which gives an opportunity for subsequent analysis.

At Eurofins EAG, we are your trusted partner in materials and advanced microscopy analysis. Our technical experts have many years of experience working with a multitude of materials and industries. Contact us today to learn how we can help you on your next project.

In this webinar we introduce Atom Probe Tomography (APT) which is a technique that provides three-dimensional (3D) chemical and spatial maps.

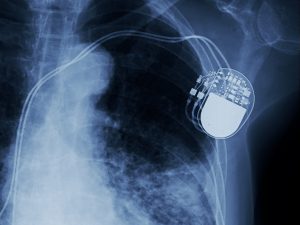

In this webinar we introduce evaluating wearable safety including product recall, lawsuits, and regulatory agency inquiries.

As medical devices become more complex, there are many more opportunities for things to go awry. Identifying, diagnosing, and remedying failures becomes dramatically more challenging. We can help.

High Depth Resolution Analysis will play a very important role in the electronic device industry as devices become smaller and smaller.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.