Ask the Expert: Surface Contact and Optical Metrology

During this live Ask the Expert event, we will answer pre-submitted questions from our audience regarding materials analysis with various surface contact and optical analytical techniques.

Home » 2D and 3D Investigations of Li-Ion Battery Electrodes

Have you ever paused to marvel at how your laptop, electric car, or smartphone springs to life with a simple button’s press? Deep within these devices lies the heart of their operation: Li-Ion battery electrodes. These intricate components are the unsung heroes, ensuring your devices power up efficiently and safely.

Li-Ion electrodes are more than just energy suppliers; they’re intricate mazes of structures and materials. Their design and intricate layout play pivotal roles in determining a battery’s capacity, discharge rate, and overall lifespan. By delving deep into their composition, we can innovate and design even better energy storage solutions for tomorrow.

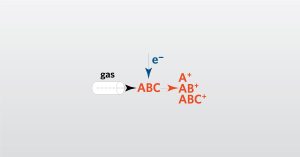

A clean surface or a slice of the sample needs to be polished/extracted before analysis by Electron Microscopy. Broad beam or Focused Ion Beam (FIB)/Scanning Electron Microscopy (SEM) polish could provide a clean cross section for further analysis including SEM/Energy Dispersive X-ray Spectroscopy (EDS). Transmission Electron Microscopy (TEM) based techniques using a thin lamella to understand more details of the battery materials.

Broad Beam Polish Techniques: These provide a bird’s-eye view, helping us understand the large-area layout of the electrodes. We gain insights into the composition and arrangement combining with SEM/EDS, crucial for improving energy storage capacity.

TEM-based Techniques & EDX/EELS: Delving deeper, these tools allow us to visualize the crystal structures and detailed compositions. From grain orientations to understanding chemical compositions, these techniques ensure we don’t miss a detail.

With one layer understood, it’s time to journey within. Our 3D investigative techniques provide a holistic understanding of the 3D structure and composition, from macro structures down to the atomic scale.

FIB SEM Tomography: This is our window to the larger grain distributions within the electrode at µm to hundreds of µm level. It helps identify cracks, fissures, and other anomalies which could impact battery performance.

Atom Probe Tomography: Taking precision to the next level (tens of nm to hundreds of nm), this tool breaks down the electrode atom by atom. By understanding the sequence and arrangement of these atoms, we gain unparalleled insights into the battery’s performance metrics.

A customer approached us with a concern: their battery’s capacity had significantly diminished after numerous cycles. They sought to understand the underlying cause of this issue. To address this, our technical experts focused on examining the battery’s cathode, a crucial component affecting its overall performance. Our analysis was aimed at verifying the cathode’s composition post-cycling.

We discovered that the cathode grain had undergone degradation, coupled with a change in its chemistry. This degradation was identified as a critical factor contributing to the capacity loss. The alteration in the cathode’s structure and chemical composition impeded its ability to efficiently store and release energy, leading to a decreased capacity.

This case highlights the importance of material integrity in battery performance, particularly under extensive use. Understanding these changes at a chemical and structural level is essential for enhancing battery life and reliability. At Eurofins EAG, our technical experts have many years of experience working with battery materials. Contact us today to learn how we can help on your next battery project.

During this live Ask the Expert event, we will answer pre-submitted questions from our audience regarding materials analysis with various surface contact and optical analytical techniques.

In this webinar we will focus on Gas Chromatography-Mass Spectrometry (GC-MS) which allows for the identification of specific molecules

As the list of restricted substances grows, testing demands customized methods to identify issues early. This is a complex issue that requires a strategic approach.

Contamination control and defect reduction are critical issues in the manufacturing process of compound semiconductor devices which can impact the performance of the end product. We can provide valuable insights to identify contaminants and characterize materials throughout the product lifecycle.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.