Analytical Investigations of Plastics & Polymers Webinar

In this webinar we introduce Analytical Investigations of Plastics and Polymers to tackle failure issues quickly and effectively

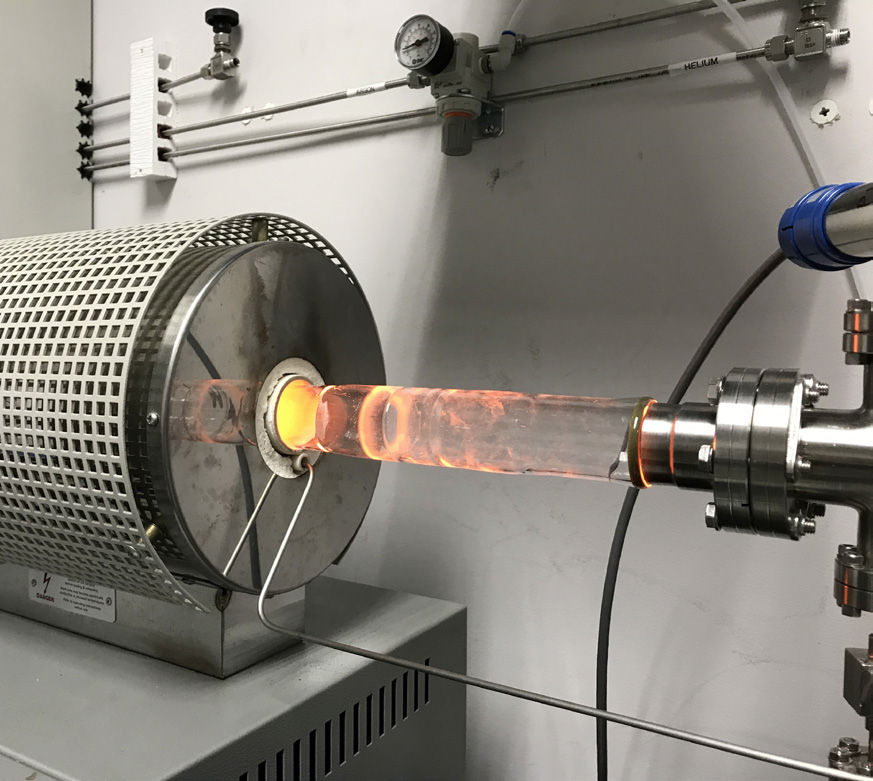

Home » Evolved Gas Analysis for Material Outgassing Characterization

There’s a lot that occurs during product development that the typical consumer is not aware of. There are various tests to identify suitable raw materials, considerations for design aspects, quality control tests, failure analyses, modifications & updates, and so much more to make a product market worthy, safe, and ready for store shelves. The average person might be surprised to discover that every material that we use has trapped gasses inside. These gasses may evolve during the operation of a particular product and can become a problem for the functionality of the product or could cause health hazards for end users. For example, moisture content above a certain level in the tiny chip inside your electronic device can result in the malfunction of the device. Similarly, the presence of certain gasses could result in rapid disintegration of a battery in your electric vehicle. This also includes harmful and toxic gasses like Fluorine (F), Chlorine (Cl), and Hydrogen Fluoride (HF). Any material can have trapped gasses and when sealed inside a hermetic device the gasses will evolve with time. For example, a pacemaker or cochlear implant (or rather any implantable medical device) contains complicated electronic parts inside of it. Over time these can get filled with trapped gasses that could fail or be lethal inside the human body. Therefore, it is critical to characterize the outgassing of any material that is part of the final product. At EAG, we have developed tools that can perform outgassing studies using a proprietary technique called Evolved Gas Analysis (EGA).

Gas molecules evolve/outgas from surfaces, solids, and/or powders when heated above room temperature. If the outgassing is performed in an ultra-high vacuum (UHV) condition, the evolved gasses can be identified without contamination from gasses from an ambient environment (mostly air and moisture) environment. Evolved Gas Analysis (EGA) is a method for monitoring trace amounts of gas molecules that can evolve from samples when heated in an UHV condition above room temperature. This analysis can be primarily used to determine: (1) the composition of the evolved gases (2) the concentration of evolved gases (3) and, the evolution profile with respect to heating temperature. This information is vital for quality control, failure analysis or establishing protocol for a manufacturing process. For example, Evolved Gas Analysis (EGA) can determine how long a part should be pre-baked to make it moisture-free before sealing it inside the final product. The other use of this technique could be finding the part that is responsible for releasing moisture above the allowed limit. This is an effective technique for a comparative study (good vs. bad), direct gas analysis, outgassing rates, and component level failure analysis for hermetic electronic components. It can also perform an experimental thermal simulation that a product can experience while under use. The released gasses can be analyzed and collected on a specially designed device. The collected gas can then be analyzed utilizing other independent techniques such as Gas Chromatography Mass Spectrometry (GCMS) or Fourier Transform Infrared Spectroscopy (FTIR), mainly to compliment Evolved Gas Analysis (EGA) results.

EAG scientists are adept at providing innovative solutions for the challenges faced by their customers during a product’s development. The Evolved Gas Analysis (EGA) technique is one of those solutions where EAG pushed the technical limit by building equipment to meet a need. This technique was specially commissioned to help a customer trying to understand what gasses were being released from their product when heated to a certain temperature. Our scientists worked with the customer and simulated the exact heating process in laboratory to survey gas species in their product. This is now a technique used routinely to profile the gas release with respect to temperature, perform failure analysis for hermetic packages, determine outgassing rates for metals, and to investigate material worthiness for use under UHV conditions. Our lab offers flexible sampling fixtures to accommodate various types of samples (solids, powders, and gas). Contact our team today for more information about utilizing the Evolved Gas Analysis (EGA) technique with your sample.

In this webinar we introduce Analytical Investigations of Plastics and Polymers to tackle failure issues quickly and effectively

December 5

During this Ask the Expert webinar, our team of battery materials experts will address your pre-submitted questions during the event, as well as present about our new battery lab’s capabilities.

In this webinar we will focus on SEM Cathodoluminescence (SEM-CL) Analyses for Materials such as compound semiconductors

In this webinar we introduce Residual Gas Analysis (RGA), Evolved Gas Analysis (EGA), and Cumulative Helium Leak Detection (CHLD)

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.