XRF Webinar

In this webinar we introduce X-ray Fluorescence Spectroscopy (XRF) which is a analytical technique used for elemental analysis of materials.

Home » Certified Testing for Aerospace and Defense Government Suppliers

The Aerospace and Defense industry has stringent certification requirements for manufacturers looking to supply this industry. This is to ensure that the product/application will not fail and to protect the lives of those who operate the finished products. These certifications are managed through The Defense Logistics Agency (DLA). DLA is the nation’s logistic support agency. The DLA manages the end-to-end global defense supply chain from raw materials to end-user disposition for the five military services, 11 combatant commands, other federal, state, and local agencies, and partner and allied nationals (DLA).1 To be a supplier to the DLA, a manufacturer must meet or exceed the Military Standards put in place for the industry of the product or service. DLA’s qualification program requires manufacturers and/or distributors to pre-qualify through an assessment of the provider’s process controls and products. The

main objective of this program is to confirm that the products supplied by manufacturers and/or distributors conform to the specification and requirements and can provide maximum assurance.

Eurofins EAG Laboratories (EAG) is certified by the DLA to perform the following test methods at its various locations: MIL-STD-883 TM 1005.11 Steady-State Life 1, MIL-STD-883 TM 1006 Intermittent Life 1, MIL-STD-883 TM 1008 2 Stabilization Bake, MIL-STD-883 TM 1010.9 Temperature Cycling, MIL-STD-883 TM 1011.9 Thermal Shock 1, MIL-STD-883 TM 1015.12 Burn-In Test 1, MIL-STD-883 TM 1018.10 Internal Gas Analysis, MIL-STD-883 Method 2023.2 Ultrasonic Inspection of Die Attach, MIL-STD-883-3 TM 3015.9 Electrostatic Discharge Sensitivity Classification, MIL-STD-883-3 Method 3023.2 Static Latch-Up Measurements for Digital CMOS Microelectronic Devices, JS-001, JS-002, JESD22-A110, and JESD22-A118.

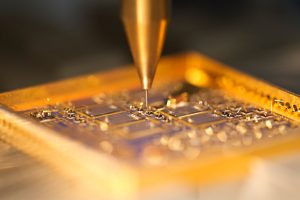

An aerospace supplier wanted to run final reliability tests on its microelectronics built to go into space. Knowing that EAG is a suitable commercial laboratory providing MIL-STD 883 TM 1018 testing they reached out for analysis. After speaking with the client, EAG analysts determined that the best technique for analysis would be Residual Gas Analysis (RGA). RGA can determine moisture content as well as an entire spectrum of gasses in the component. The RGA test showed that the parts had hermetic issues. There was a higher level of moisture with traces of Fluorocarbon. Fluorocarbon can get into a part during the gross leak test and plug the leak path; causing a part to escape detection during leak testing.

Since the RGA test shows the full spectrum, EAG scientists concluded that there was a problem with the clients sealing process. In addition to RGA, EAG’s experts identified the origin of the “problem” internal gasses and provided corrective action to the customer. As a full-service solution provider, EAG wanted to ensure that they identified all possible issues and provided solutions to eradicate them.

In 2022, EAG was approved as a suitable commercial laboratory to provide MIL-STD 883/750 TM 1018 Internal Water Vapor Content Testing for hermetically sealed electronic devices. The MIL-STD 883/750 Test Method 1018 is part of the assessment and mandatory for the hermetic devices supplied by qualified suppliers. The MIL-STD 883 standard establishes uniform methods, controls, and procedures for testing microelectronic devices suitable for use within Military and Aerospace electronic systems including basic environmental tests to determine resistance to deleterious effects of natural elements and conditions surrounding military and space operations; mechanical and electrical tests; workmanship and training procedures; and such other controls and constraints as have been deemed necessary to ensure a uniform level of quality and reliability suitable to the intended applications of those devices.

Aerospace and defense government suppliers can have confidence in EAG’s credibility in providing accurate and high-quality testing services. Contact EAG today to learn how we can be your partner with DLA-suitable testing. Working with EAG will bring breadth and depth of testing methodologies and experience, worldwide testing capabilities, consulting experience, and the highest level of customer confidentiality. EAG is the One-stop-shop for all testing and analytical needs.

In this webinar we introduce X-ray Fluorescence Spectroscopy (XRF) which is a analytical technique used for elemental analysis of materials.

DPA in the aerospace industry is essential for maintaining high levels of reliability, ensuring compliance with standards, conducting thorough quality control, and analyzing failures.

Measuring the chemical state of the battery components such as the cathode, anode, separator, electrolyte, contact layers and additives, at various stages of cycling, provides vital information about the electrochemical processes that occur during battery use.

Cracks were observed in transparent thermoformed plastic packaging during visual quality checks. Failures occured in specific material lots.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.