Utilizing High Depth Resolution for Measuring Layers at an Atomic Level

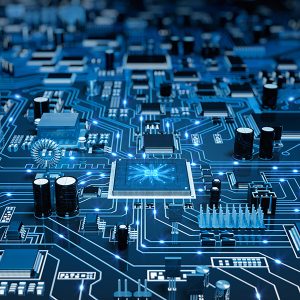

High Depth Resolution Analysis will play a very important role in the electronic device industry as devices become smaller and smaller.

Home » Glass as a Critical Player in the Pharmaceutical Industry

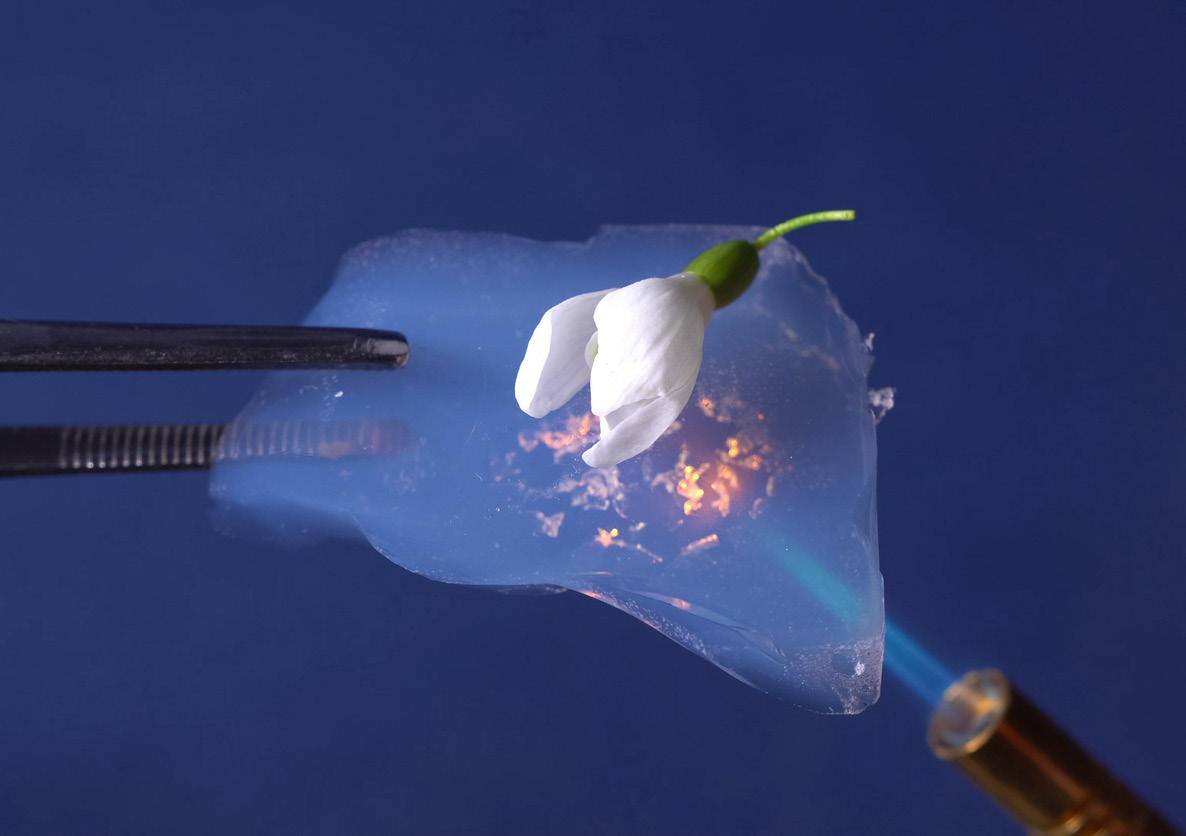

Glass is everywhere. We see it every day via our cell phone screens, through our television/computer screens, looking out a window at home, work, or while driving our car, or out a cup we may drink our favorite beverage from. Glass is a material that is frequently utilized in our everyday lives as it is a crucial element to numerous applications. Many decorative items have been created from glass over the centuries such as Egyptian glass beads, mosaic glass, and fine tableware. One critical glass creation lies within the pharmaceutical industry – specifically, in glass vials used for storing drugs.

Glass is an inorganic solid material that is usually transparent or translucent as well as hard, brittle, and impervious to the natural elements (Britannica). It is made by cooling molten ingredients such as silica sand with sufficient rapidity to prevent the formation of visible crystals. The varieties of glass differ widely in chemical composition and in physical qualities

Commercial glasses may be divided into soda-lime-silica glass or special glass – where the highest level of productions comes from soda-lime-silica glass. Such glasses are created from three main materials: sand (silicon dioxide, or SiO2), limestone (calcium carbonate, or CaCO3), and sodium carbonate (Na2Co3) (Britannica).

For the Pharmaceutical Industry, glass plays a vital role in drug storage/transport. It is pertinent that a drug’s chemistry does not change if stored in a glass vial over a period of time. For a given container at different locations the surface chemistry is different which could lead to degradation (or glass corrosion). Sometimes, if the surface is not ideal, the glass vial can react with the drug so badly that small glass particles can flake off and float into the drug which can then float into one’s bloodstream intravenously. For this very reason glass manufacturers take care to develop different compositions of glass so that they do not react to the drug solution.

For over 40 years, EAG has been involved in the entire glass value chain, from raw starting material to final products. EAG scientists investigate the composition and quality of raw materials and production glass, give research and development support to glass factories during process optimization, glass tank wear-out studies, verification tests and failure analysis investigations. But also, in the field of surface modification, delamination and corrosion of coatings, EAG has unmatched expertise. Specifically related to the pharmaceutical industry, EAG utilizes Secondary Ion Mass Spectrometry (SIMS) to examine the changes in composition at different locations within the vial structure.

For assistance in determining if your product has the correct composition, please contact us to speak with someone from our team.

Britannica, The Editors of Encyclopedia. Glass. 14 June 2023. 7 August 2023. <https://www.britannica.com/technology/glass>.

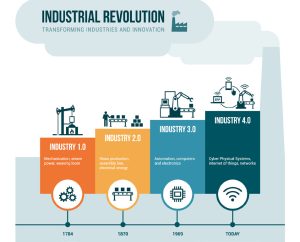

High Depth Resolution Analysis will play a very important role in the electronic device industry as devices become smaller and smaller.

Developing a reliable product has many challenges due to the desire for increased capability, reduction in formfactor, and managing the supply chain.

The Versatility and Usefulness of Aerogels Thermal resistance and its complement, thermal conductance, are fundamental concepts in thermodynamics, thermal engineering, and heat transfer. They describe the ability of a material

In sectors like the automotive industry, ATE plays a pivotal role in verifying the proper and reliable operation of critical systems.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.