Particle Characterization Webinar

In this webinar we introduce Particle Characterization by analyzing and reducing particulate matter and contamination

Home » FTIR and Raman – Composition and Contamination Analysis

What is that material? Where does that material come from? Just like a young child full of curiosity, we as adults sometimes wonder what our everyday products are made of. Or in other words… how durable they are and how long they’ll last? Products are designed and manufactured using specific materials and properties in mind. These materials and properties are typically dependent on industry standards or the end-use of that product.

Sometimes we discover that a contaminant or residue is causing a product to fail and the same questions arise… what is that contaminant and where did it come from? Fourier Transform Infrared Spectroscopy (FTIR) and Raman Spectroscopy can help answer these questions.

FTIR and Raman have many common applications as well as common industries they serve such as medical devices, consumer electronics, semiconductors, pharmaceuticals, aerospace/defense and others. Both FTIR and Raman are spectroscopy techniques that provide molecular information from various types of materials. An accurate identification of a specific compound can be determined, which is useful to characterize materials and trace back potential sources of residues and contaminants.

With all the similarities between the two techniques, how would you determine which technique to use? One of the key differences is the size of the analysis area. FTIR has a minimum sample size of ~50 to100 microns while Raman can analyze down to ~1 to 2 microns. In addition to the size limitations, the type of material can affect the choice of technique.

FTIR is preferred for organic analysis on materials such as plastics and polymers. There are much more extensive libraries for FTIR spectra of over 300k materials, which offers a significantly better chance of identifying unknown materials, while Raman only has about 55k reference spectra.

Raman is the better choice for possible inorganic materials such as metal oxides and ceramics because of the wider range of diagnostic bands it shows compared to FTIR where inorganic materials produce fewer signature vibrational bands useful for unique identification.

A very unique and powerful application that Raman provides is for carbon analysis.

Raman can identify and characterize the C-C bonding (i.e., sp2 vs sp3) in many different types of carbon allotropes such as graphite, diamond, graphene, carbon nanotubes and DLC (diamond-like carbon). The type and percentage of sp2 vs sp3 bonding in the carbon materials can strongly affect their physical properties and performance in the end application. For example, deposition conditions and parameters used for DLC film fabrication can change the bonding chemistry in the film which further affect its properties. Compositional information obtained from Raman analysis can provide guidance on fine-tuning the process and deposition parameters to achieve quality control over the film properties. In the battery industry, Raman can determine the graphite chemistry as well as grain size in the electrode materials helping to better understand their performance in battery applications.

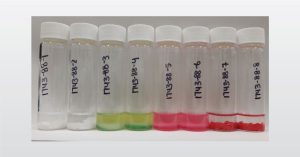

We also offer mapping capabilities with our Raman analysis to provide either 2D mapping to study distribution of different materials as well as depth profiles to study change of material composition as a function of depth. This is widely used in the pharmaceutical industry to determine if there is a homogenous distribution of the active and inactive ingredients of a pill which can help determine the effectiveness of the release of an ingredient.

Although both are spectroscopic techniques, FTIR and Raman provide complementary information under a lot of circumstances as the scientific principle behind the two techniques is different, giving them their unique strengths for material characterization. Therefore, a combination of FTIR and Raman analyses is often recommended especially for unknown material characterization so that a more comprehensive understanding of the identity and composition can be achieved.

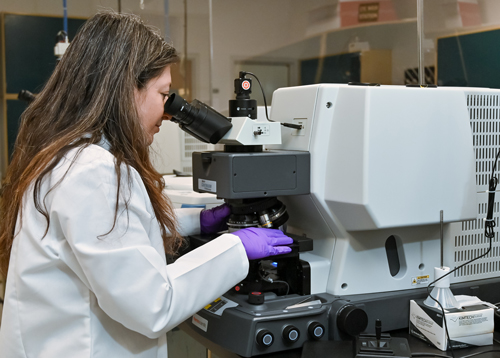

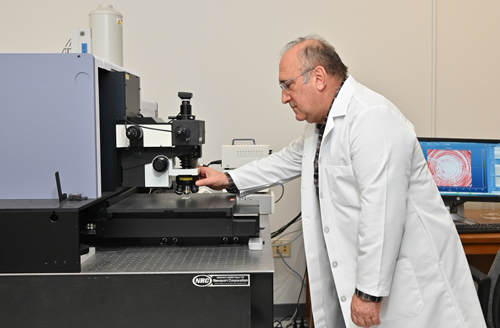

At Eurofins EAG, our FTIR and Raman experts are highly experienced leaders in the analysis of a wide range of materials, especially complex mixtures. We pride ourselves in skillful sample preparation, knowledgeable spectral interpretation and extensive experience with materials for various applications. We provide accurate data, complete written reports, fast turnaround times, and direct person-to-person service.

Contact us today to learn how we can help you on your next project.

In this webinar we introduce Particle Characterization by analyzing and reducing particulate matter and contamination

In this webinar we introduce the analytical approaches for solving food and beverage challenges including contamination.

VCSELs have several advantages, such as a higher modulation speed, which make them great for technological innovations.

EAG scientists are leaders in the lithium-ion batteries recycling arena. EAG is a valuable resource in understanding these materials.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.