Liquid Particle Counter (LPC)

Home » Our Techniques » Liquid Particle Counter (LPC)

EAG laboratories offers a full portfolio of particulate matter testing using several measurement techniques. Techniques like liquid particle counter (LPC), light microscopy, FTIR and SEM-EDX are available for particle counting, sizing, and identification.

The liquid particle counter is an analytical technique used to quantify particulate contamination suspended in liquid by detecting and sizing particles using light obscuration. In the case that the cleanliness of material or a product should be examined, particles should be extracted from the surface into a clean liquid, usually water. Sample handling is typically done in a controlled environment to avoid external contamination.

- The LS-20 uses a laser-diode light source and collection optics to detect particles as they pass through a flow cell. Particles block light from the laser, and the duration of this blockage is used to count and size them. Sizing is performed across eight calibrated channels, detecting particles from 1.0 to 50 microns.

- The LS-60 is based on light scattering, enabling detection of smaller sized particles, ranging from 0.2-2 microns, by measuring the light deflected as particles pass through the laser beam. It is commonly used in the semiconductor industry.

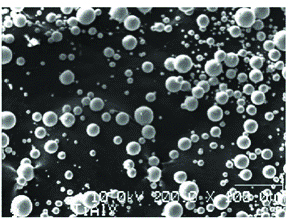

Particle identification can be achieved by extracting the particulate contamination from suspension onto a filter, followed by surface analysis using Fourier Transform Infrared spectroscopy (FTIR) for organic compounds and scanning electron microscopy with energy-dispersive X-ray spectroscopy (SEM-EDX) for inorganic materials. In case of SEM, the morphology of the particles can be studied as well. The liquid particle counter is predominantly used for quality control and contamination monitoring, with more specific applications in the medical industry (such as, catheters, stents, needles, etc.), dental tools, plastic components, and more. Moreover, LPC instruments play a role in cleanliness assessments and process optimalization in manufacturing environments, helping to ensure compliance with industry standards such as USP788.

Ideal Uses of LPC

- Compliance testing of medical devices and dental products

- USP788 testing

- Assessing the effectiveness of cleaning procedures

- Evaluation of the impact of materials or processes on particle contamination

Strengths

- Quantitative

- Widely applicable

- Fast

- Compliance with regulatory standards

Limitations

- Sensitive to sample preparation. Incorrect handling can significantly increase the number of particulates measured

- A relatively large sample size is required for proper particle number evaluation

- No possibility to determine the nature of the particles

Would you like to learn more about using Liquid Particle Counter (LPC)?

Contact us today for your Liquid Particle Counter (LPC) needs. Please complete the form below to have an EAG expert contact you.