Additive Manufacturing: Analysis Along the Entire Value Chain

Home » Additive Manufacturing: Analysis Along the Entire Value Chain

Additive Manufacturing, also referred to as 3D printing, has become an established manufacturing process that enables the creation of a variety of products with freedom in design and choice of material (polymers, metals, ceramics).

After enabling the production of customized consumer products, Additive Manufacturing has entered the medical, aerospace, and automotive industries. The high demands on product quality in these sectors has substantiated the need for advanced materials characterization, often according to standards.

Analyzing the Value Chain

To ensure a reproducible production process, and optimal product performance and lifetime, analysis is required along the entire value chain: From concept and research to prototype design and process verification to post-market surveillance.

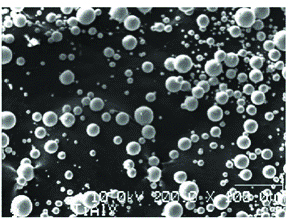

- Raw materials (feedstock) – The properties of the raw material have a strong influence on the quality of the final product. Characterizing the chemical composition, purity, particle size, morphology, batch-to-batch variation, homogeneity, etc. will contribute to the production of reproducible, high-quality parts and products.

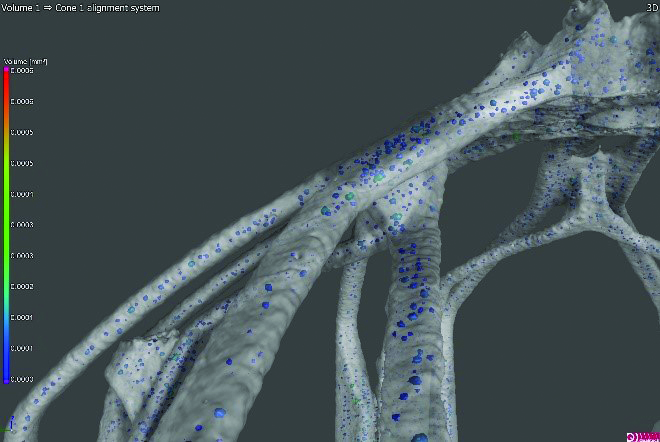

- Process optimization – Correlating process parameters and their variance to product properties is crucial for process optimization. By characterizing processed parts and products, the defect density, porosity and roughness can be minimized, and the compositional homogeneity and mechanical properties can be optimized.

- Finished parts/products – Assessing the quality and reliability of produced parts and products.

- Aging – Accelerated lifetime studies to gain insight into degradation mechanisms.

- Failure analysis – What if the final part breaks or does not reach the required specifications? What is the root cause? How can we learn from it, anticipating for the future?

Would you like to learn more about Additive Manufacturing?

Contact us today for your Additive Manufacturing needs. Please complete the form below to have an EAG expert contact you.