Analysis of refractory materials

Home » Analysis of refractory materials

Corrosion of the inner walls of glass tank furnaces is a well-known source of defects in glass. Refractory materials that are typically used in glass tank furnaces are zirconia, alumina and silica-based bricks. Other oxides of magnesium or calcium might be applied as well. The materials should have high mechanical strength, excellent thermal shock stability and good corrosion resistance to liquid glass and gaseous reaction products. Temperature and chemical corrosion and mechanical erosion issues can however occur in time, resulting in an increase in the number of glass faults or defects.

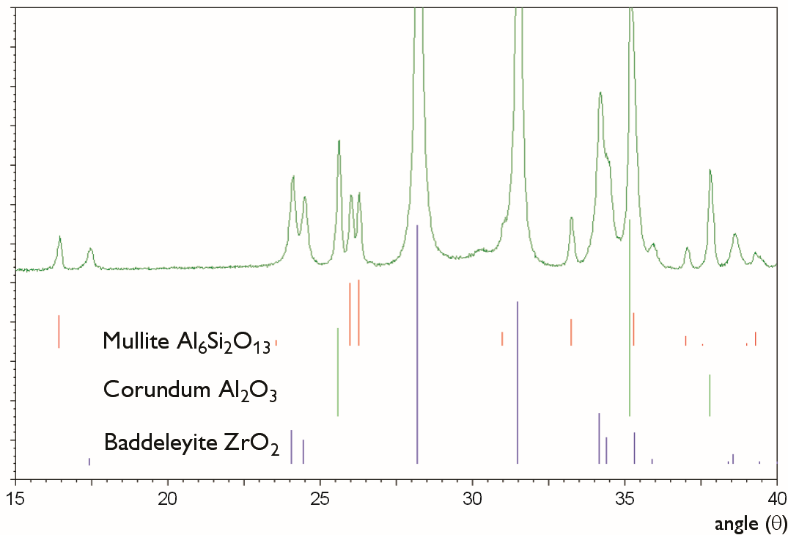

Crystallographic phase identification using X-ray diffraction

In an X-ray diffraction (XRD) pattern the position and intensity of the maxima are characteristic for the crystallographic structure and the atomic composition of the material. In case of a multi-phase composition, the resulting pattern is a combination of the patterns of all structures present. Phase identification can be done by matching the XRD pattern with reference patterns of pure substances.

Common applications:

- Phase identification of refractory material

- Identification of (heavy) minerals

- Crystallographic data of large stones

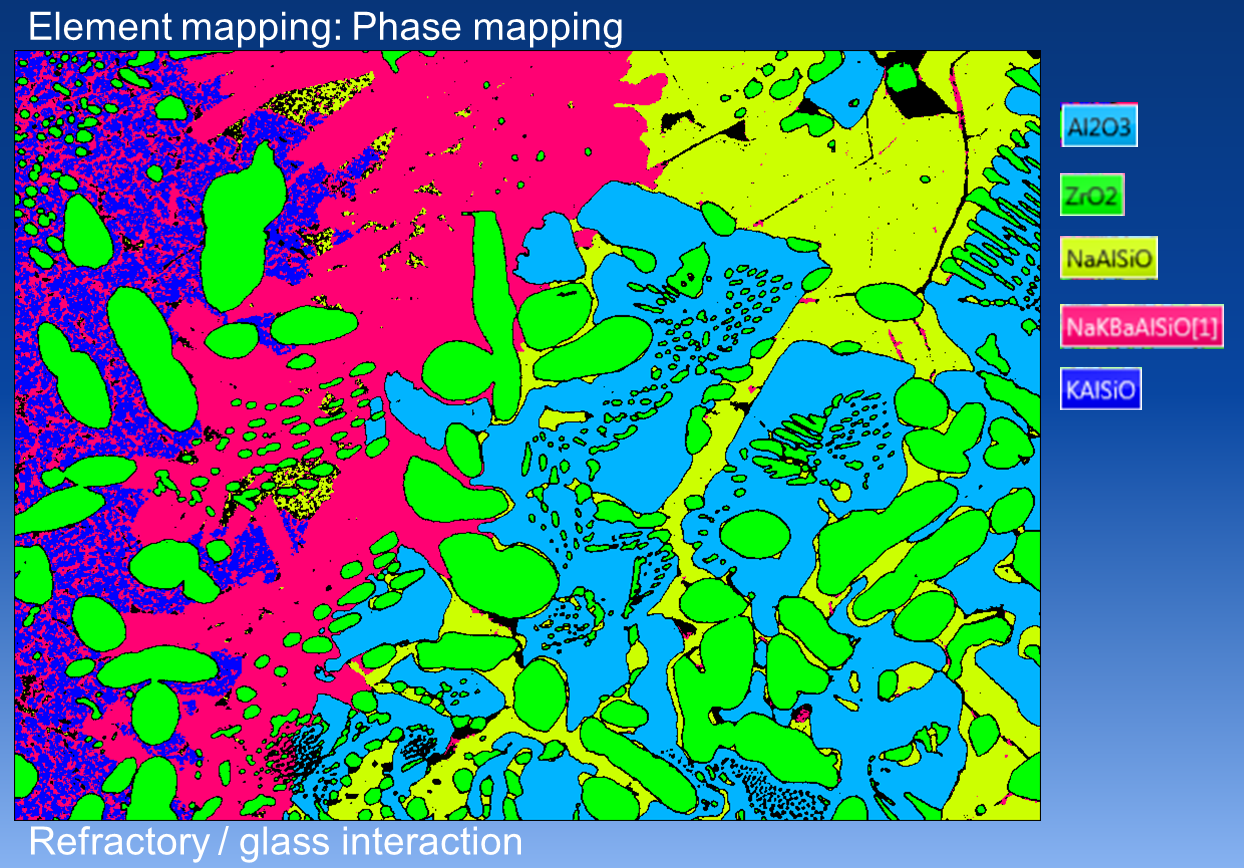

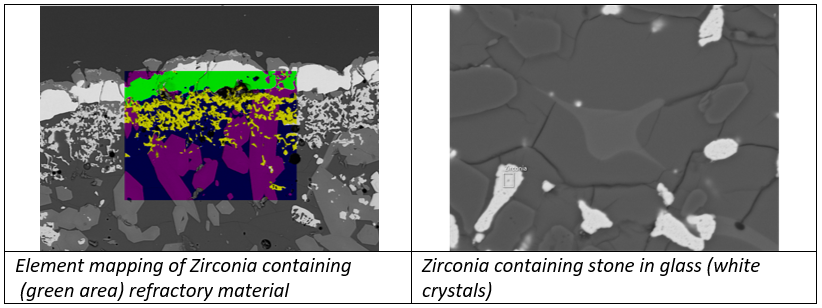

Electron microscopy studies of the microstructure

In order to gain more understanding on the source of the inclusions found in the glass products, a detailed inspection of the refractory materials is essential. Scanning Electron Microscopy (SEM) combined with Energy Dispersive X-ray Spectroscopy (EDX, or EDS) provides insight into the interface reactions between the furnace walls and the glass.

Would you like to learn more about analysis of refractory materials?

Contact us today for your analysis of refractory materials needs. Please complete the form below to have an EAG expert contact you.