Biomedical Applications of AFM: Imaging Hydrogel Coatings

Home » Biomedical Applications of AFM: Imaging Hydrogel Coatings

Materials used in medical devices must not only have appropriate structural and mechanical properties, but cannot provoke severe bodily reactions and ideally should promote a healing response. Medical device designers use various surface treatments, including the use of bonded coatings, to meet the need for functionality and biocompatibility. The application of coatings to the surface of medical devices can enhance or modify properties such as lubricity, hydrophobicity/hydrophilicity, and biocompatibility. For instance, medical device designers are exploring the use of coatings such as heparin on coronary stents to reduce the occurrence of thrombosis and restinosis. Many catheters are coated with hydrogels. Hydrogel coatings make catheters lubricious when moistened, easing insertion without making pre-insertion handling difficult.

It is important for the manufacturer to understand how the coating behaves when applied to a surface. Techniques such as conventional electron microscopy have difficulty imaging thin coatings on non-conducting samples. Also, since electron microscopy is normally a high vacuum technique, the sample must be completely dry. Since water is the main constituent (>80%) of hydrogels, working in a vacuum presents serious obstacles. On the other hand, Atomic Force Microscopy (AFM) works equally well on insulators or conductors, and can image both dry and wet samples. AFM imaging analysis generates high-resolution topographic information not readily available from other techniques.

AFM RESULTS

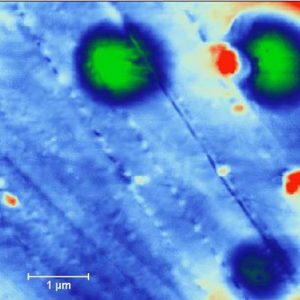

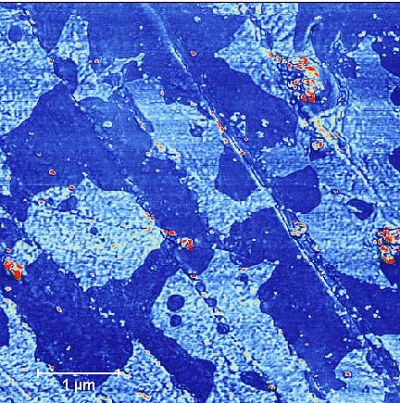

Figure 1 shows the surface topography of a 5µm x 5µm area of a polyurethane tube coated with a lubricious hydrogel. The colors indicate the height of the surface — dark blue being low, red being high. The height (Z) range is 100 nanometers. Figure 2 is a phase image of the same area and was acquired simultaneously with Figure 1. Phase images display the phase lag of the oscillating cantilever relative to the driving force as a function of lateral position. The phase lag is sensitive to differences in the material properties within a sample. In this case, the image shows that the coating has areas with different physical characteristics. These different areas are not readily apparent in the height image of the tube.

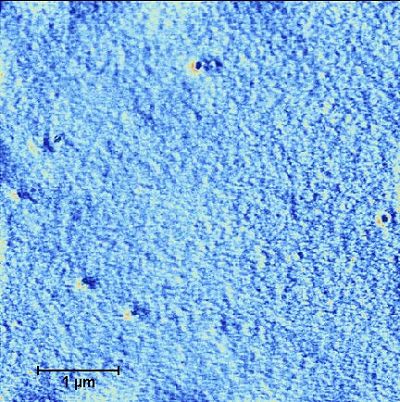

After the tube has been moistened; however, the surface of the tube becomes quite uniform, as seen in Figure 3. This indicates that the addition of water has dramatically changed the characteristics of the coating. While this image of the moistened tube was made under ambient conditions, the sample could also be imaged while under fluid. AFM is unique among analytical techniques in its abilities to:

- Produce extremely high-resolution images

- Provide information on both topography and physical properties

- Image non-conducting samples

- Image under ambient or controlled conditions

- Require no sample preparation

Would you like to learn more about Biomedical Applications of AFM?

Contact us today for your biomedical application of AFM needs. Please complete the form below to have an EAG expert contact you.