Chemical Decapsulation Services (Decap)

Home » Chemical Decapsulation

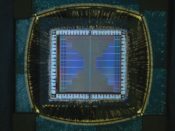

Chemical Decapsulation (Decap) is the creation of a cavity on the package surface of an electronic component such as a DIP, BGA, QFN or other types of packages to expose the die underneath for inspection.

This can be achieved by using a chemical etcher or by creating a shallow cavity on the package surface with a laser etcher and manually dropping acid on the package over a hot plate.

Decap services at EAG involve wet chemical etches to remove the plastic encapsulant on devices to allow inspection of the die. These involve precavitation by laser followed by the use of various acid solutions. Devices with aluminum or gold bond wires are standard and those with copper wires require a more involved process. Devices may be decapped individually or while mounted on a PCB.

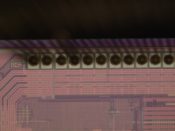

Normal Decap with Gold Wires

Normal Decap with Copper Wires

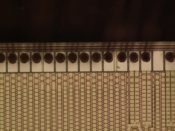

Decap with the Lead Fingers Exposed

Note: Laser is used to expose the lead fingers after the die is exposed by acid.

Non-ideal Decap Results

Would you like to learn more about Chemical Decapsulation?

Contact us today for your chemical decapsulation needs. Please complete the form below to have an EAG expert contact you.