Particle Size Characterization

Home » Particle Size Characterization

Particle size is an important parameter for many industrial processes. The chemical, optical and mechanical properties, the mixing behavior and the bio-distribution of many raw materials and end-products are affected by the size and shape of their particles. Therefore, monitoring particle dimensions is an important step in product optimization.

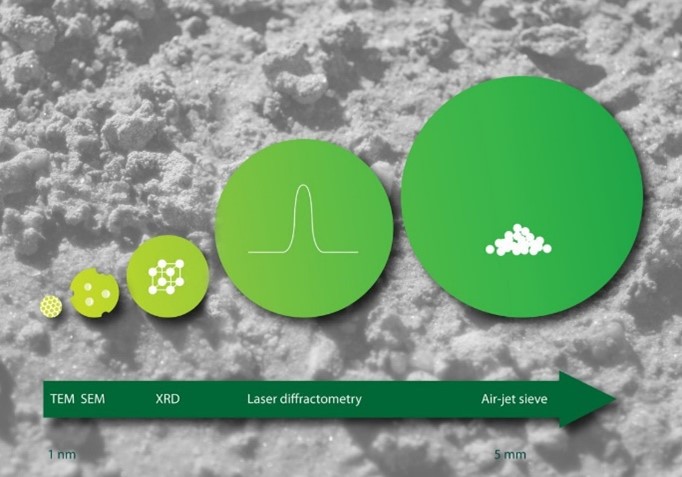

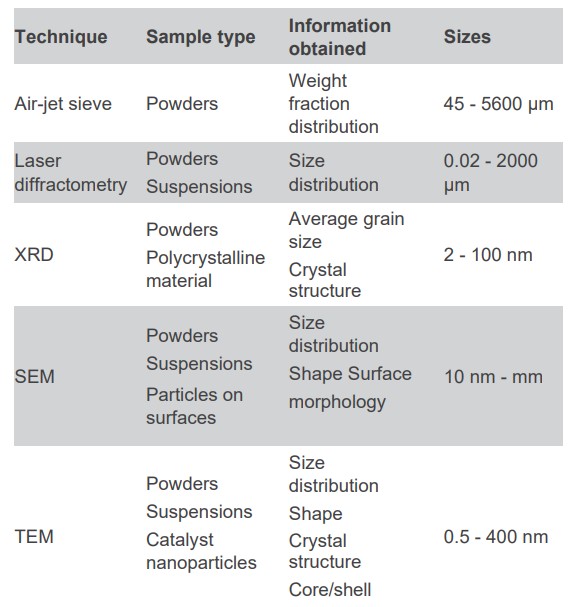

Portfolio of Analytical Techniques for Particle Size Characterization

Eurofins EAG Laboratories offers a full portfolio of particle size measurement techniques, as presented in Table 1. Together, the techniques cover a range of more than six orders of magnitude in particle dimensions. Here, you can learn more about the five different techniques that are applied to span the entire range of particle sizes.

Air-Jet Sieve Analysis

Dry powders are placed on a sieve. This sieve is mounted in an airtight container. Air is blown upwards through the sieve from a rotating nozzle to fluidize the sample. The exit airflow carries undersized particles downward through the sieve. Starting with the finest sieve, the amount of material passing is determined by weighing. The retained sample is transferred to the next larger sieve size, and the procedure is repeated until sieving has been done on all required sieves in succession.

Laser Diffractometry

A suspension is pumped through a measuring cell and illuminated by a laser beam. When particles of different sizes pass a laser beam, they cause the laser light to be scattered at angles that are inversely proportional to the particle size. The angular scattering intensity data is analyzed to calculate the size of the particles, using the Mie scattering or Fraunhofer diffraction theory. The analysis technique is applicable to both suspensions and powders.

X-ray Diffraction (XRD)

When X-rays are directed on a material of which the atoms are regularly arranged, the radiation is diffracted in specific directions. XRD uses this phenomenon to study the crystal structure and microstructure of crystalline solids. The limited sizes of crystallites in a powder or polycrystalline material broaden the peaks in the diffraction profile. This effect can be used to determine the size of small (< 100 nm) crystallites, i.e. the size of single- crystalline domains within a particle or bulk material.

Scanning Electron Microscopy (SEM)

SEM is an imaging and analysis technique based on the detection of electrons and X-rays that are emitted from a material when irradiated by a scanning electron beam. Both topographical and compositional information can be obtained with high spatial resolution. Imaging allows us to distinguish between primary particle and agglomerate sizes. Dedicated software allows for automated image analysis, e.g. to determine particle size distributions.

Transmission Electron Microscopy (TEM)

TEM is a microscopy technique that allows for high resolution imaging as well as for chemical and structural studies on an atomic scale. An image is formed by electrons that have passed through the sample. Suspensions can either be studied after drying on a supporting film or can be quench-frozen, allowing for inspection of particle properties in the aqueous state. Using our high-end, probe- corrected TEM, particle sizes down to single atoms can be imaged in case of e.g. Pt catalysts on support materials.

Applications

- Powders (e.g. phosphors, ceramics, raw materials for glass production)

- Suspensions of ceramic materials

- Colloidal suspensions (e.g. nanoparticles for bio-applications)

- Poly-crystalline material

- Particles on surfaces

- Catalyst nanoparticles

Would you like to learn more about Particle Size Characterization?

Contact us today for your particle size characterization needs. Please complete the form below to have an EAG expert contact you.