Surface Characterization of Antibacterial Coated Sutures

Home » Surface Characterization of Antibacterial Coated Sutures

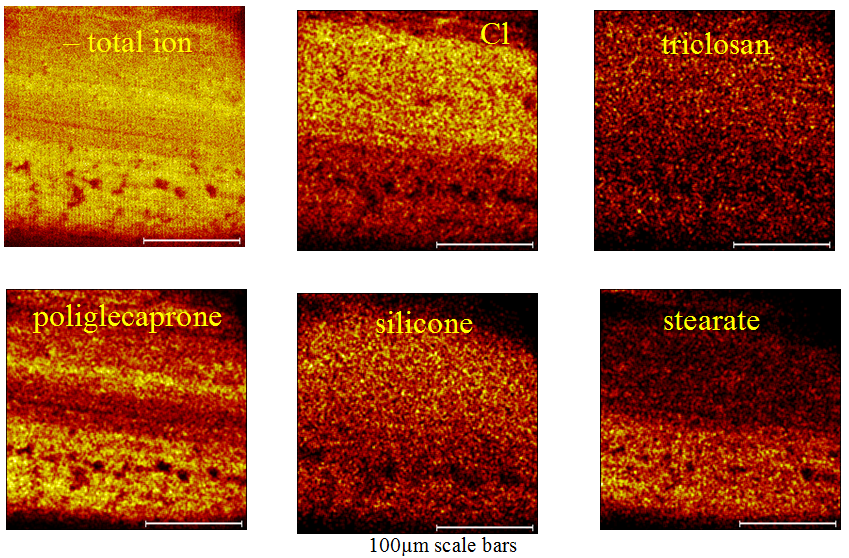

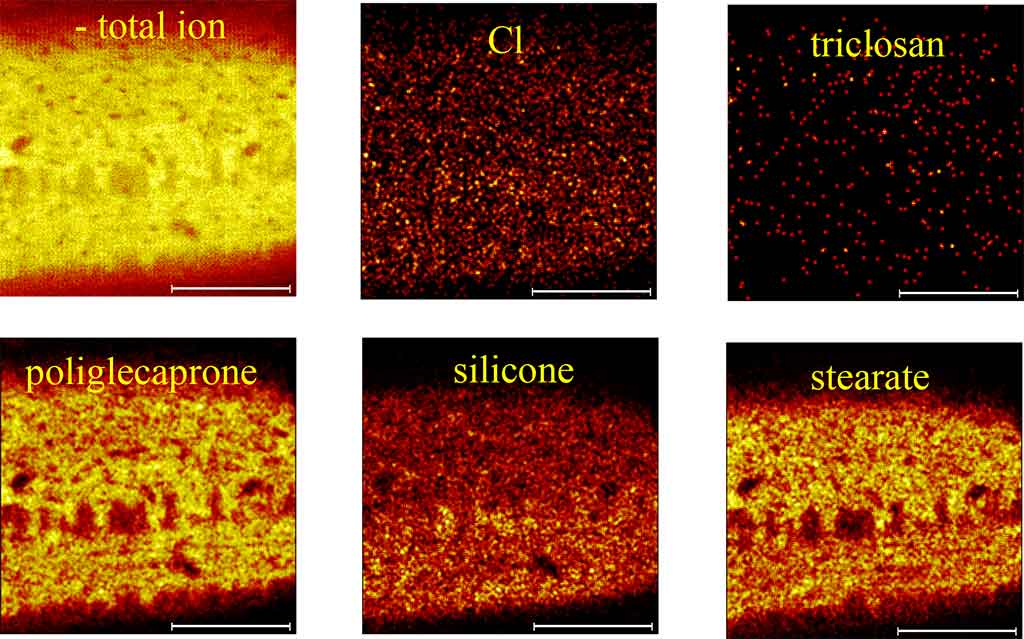

Antibacterial coated sutures have been developed to reduce the occurrence of surgical site infections. Triclosan has been used in coatings on poliglecaprone based sutures. Understanding the surfaces of suture coatings is important for failure analysis and quality control.

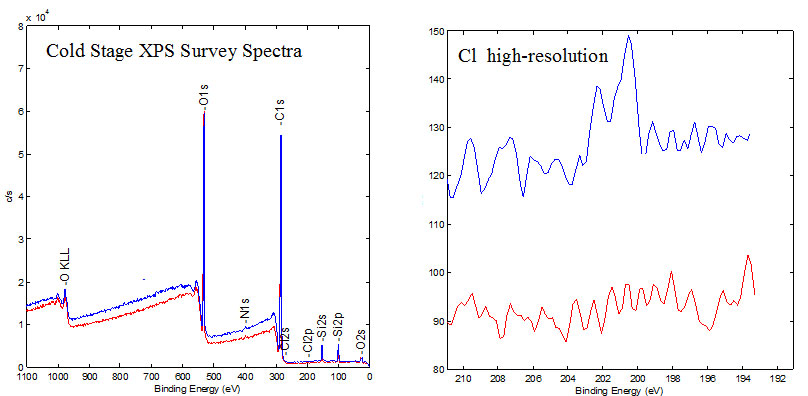

Analysis of the triclosan itself is difficult because of its volatility in the UHV vacuum systems used for instruments sampling the top few angstroms of a surface, such as Time-of-Flight Secondary Ion Mass Spectrometry (TOF-SIMS) and X-ray Photoelectron Spectroscopy (XPS).

Cold stage analysis has been shown to be effective for samples that are not solids at room temperature or that have components that are volatile in a vacuum system – such as the sutures. Samples are cooled to near liquid nitrogen temperatures outside the vacuum system and then pumped down to UHV pressures for analysis. Cold stage options are available for TOF-SIMS and XPS at EAG Laboratories.

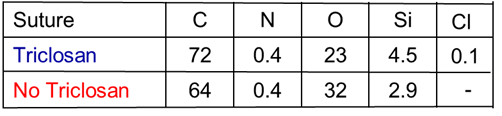

In the cold stage XPS analysis of the suture, Cl from the triclosan was detected. The spectra were compared to a suture having no triclosan coating. While the levels are low, the Cl 2p doublet is clearly present – best illustrated in the high resolution spectra.

XPS provides a semi-quantitative measurement of the triclosan while TOF-SIMS is only relatively quantitative but is more chemically specific. These techniques are often combined for a fuller understanding of the chemistry of a sample surface.

Would you like to learn more about Surface Characterization of Sutures?

Contact us today for your surface characterization of antibacterial coated sutures. Please complete the form below to have an EAG expert contact you.