XPS Analysis of Surface Modified Polymers

Home » XPS Analysis of Surface Modified Polymers

Polymer materials are ubiquitous in medical devices, automobiles, electronics, food packaging and in a wide range of industrial and consumer products. 1,2 The surfaces of these materials can be modified for a variety of reasons: to harden the surface, to reduce or increase the surface reactivity, to alter the surface roughness, etc.3,4

One of the common methods involves using a plasma to etch the surface or to introduce custom functionality to the surface.5,6 The modification needs to be the one specifically desired and be free from contamination. The ability to check the results of the treatment is key is successful method development.

Plasma alteration of surfaces is a well-known process. The high energy in a plasma creates energetic species which can react with the polymer surface and create volatile compounds that leave the surface, thereby etching the surface, or make nonvolatile compounds which either create a thin barrier which stops further reaction or reduces further penetration into the material.

X-ray Photoelectron Spectroscopy (XPS) is a well-established surface analysis tool .7,8 XPS is used to examine the surface elemental and chemical composition, providing atomic composition (excluding H and He) with detection limits in the 0.1 to 1% range. The surface is probed with X-rays which force electrons from the sample to be ejected. Electrons from the top 50-100 Å can escape the surface and their kinetic energies can be measured. Spectra are often displayed on a ‘binding energy’ scale which is basically the kinetic energy of the emitted electrons subtracted from the energy of the impinging X-rays. The carbon bonding states are determined by use of high-resolution scans.

Sample preparation

Extruded sheets of polypropylene (PP) and polycarbonate (PC) are investigated before and after exposure to O2 and F-containing plasmas (a total of six samples). The surfaces of each sample are analyzed as received (cleaned by IPA wipe) and after O2 or F plasma treatment (20 min at 100W with a partial pressure of 45 mTorr). The chamber is cleaned between each plasma exposure and the samples are run together in each plasma treatment process.

Data

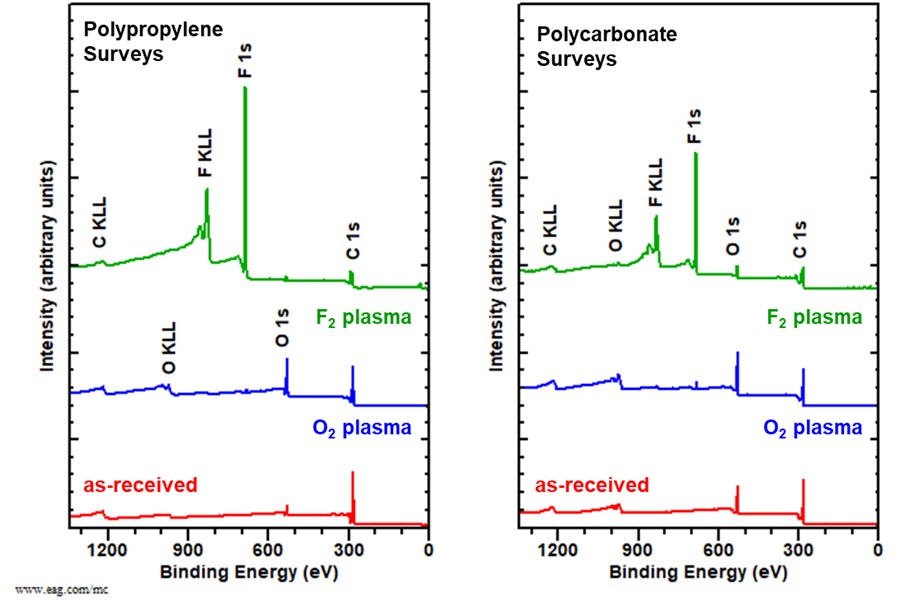

The XPS data is collected with a monochromatic source of Al K Alpha. Survey spectra for all six samples are shown in Figure 1.

The relatively low energy resolution of the survey spectra is perfectly adequate for determining the atomic composition of surfaces, but high energy resolution scans are needed to identify functional groups and/or oxidation states.9,10

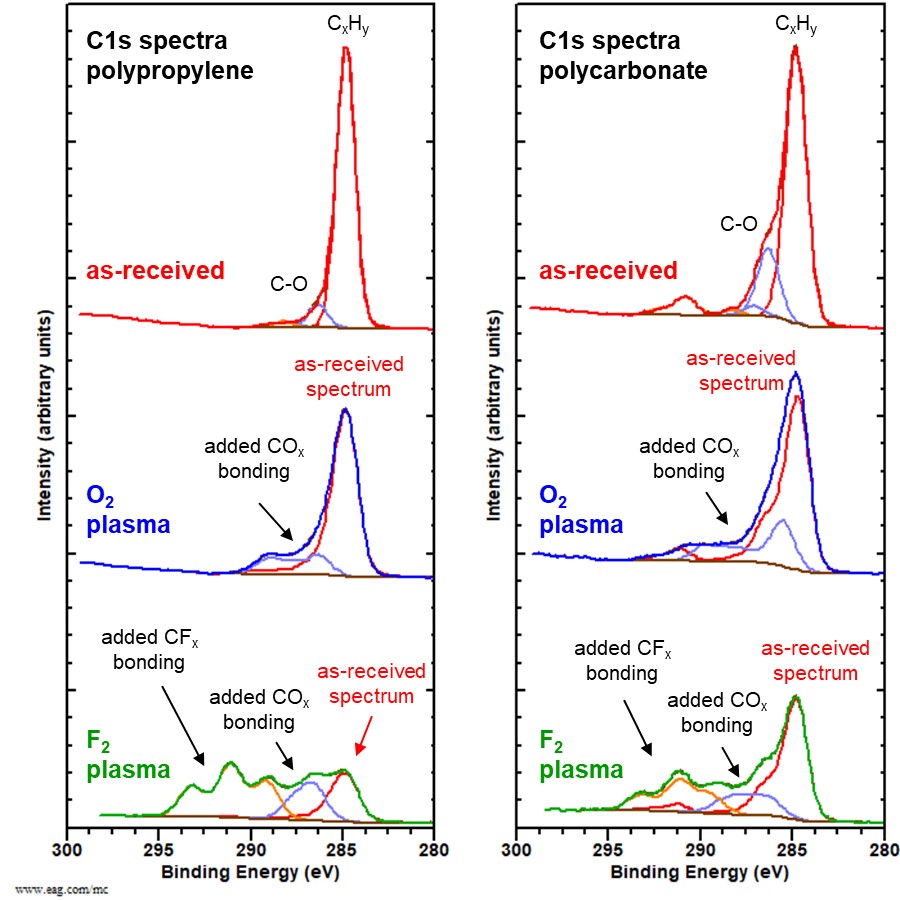

The high-resolution spectra of the C (1s) peaks are shown in Figure 2. All contain the C-C hydrocarbon bond at 284.8 eV. The carbon-oxygen functionalities in polycarbonate can be seen in the shoulder between 286-289 eV and the p →p* transition indicative of aromaticity is observed at 291 eV. The O2 plasma samples show an increase in carbon-oxygen functionalities relative to the as-received samples. This is seen in the increase in the intensities of the peaks at higher binding energies.

The samples exposed to the F-containing plasma show a substantial reduction in the C-C peak indicating a high amount of surface reactions. The peaks above 291 eV are attributable to multiple forms of CFx bonding. Some of the carbon-oxygen functionalities have also been shifted to higher binding energies due to their nearest-neighbor proximity to F atoms.

Discussion

The alteration of the surface composition: an2 increase in O due to O2 plasma and F due to F plasma treatments is clearly shown. The addition of high resolutions scans enables further information on the chemical bonding at the surface to be obtained. The as received C(1s) spectra contain hydrocarbon and multiple carbon-oxygen bonding forms.

After the O2 plasma treatment the relative amount of C-O, and C=O species increases. After the F plasma exposure, the CF, CF2, and CF3 species are observed from both samples.

The plasma treatments affect the two polymer materials differently, but similar surface functionalities were introduced.

Summary

In this study, it was demonstrated that XPS is a useful tool for evaluating the surface composition (elemental and chemical state information) of two polymer types (polycarbonate and polypropylene) before and after plasma treatment. The alteration of the surfaces by plasma treatment is clearly discerned and the detailed changes in chemical bonding are seen in the survey and high-resolution spectra. With some work, the relative intensities of the C/O or C/F peaks may be used to determine the depth of the altered surface chemistry if less than ~ 100 Å.

Other complimentary techniques can be used to investigate the effect of surface modification on topology (AFM), surface tension (contact angle), and molecular chemistry (FTIR and TOF-SIMS).

Would you like to learn more about XPS Analysis of Surface Modified Polymers?

Contact us today for your XPS analysis of surface modified polymer needs. Please complete the form below to have an EAG expert contact you.