The Power of SEM-EDS in Imaging and Elemental Analysis

SEM equipped with EDS can capture detailed images and identify elements simultaneously on the surface of samples.

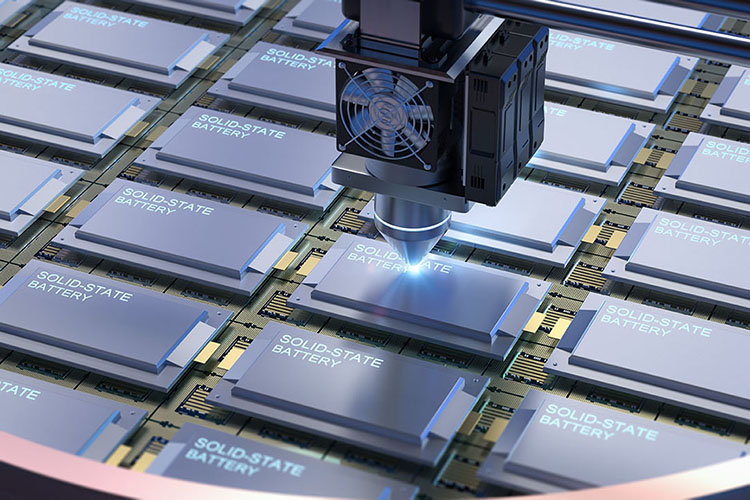

Home » Solid-State Batteries: Powering the Next Generation of Energy Storage

From the phone in your hand to the car in your driveway, lithium-ion batteries (LIBs) power nearly every corner of modern life. While demand for more power, faster charging, and longer life continue to surge, traditional liquid electrolyte-based batteries are reaching their limits. The next leap forward lies in solid-state batteries (SSBs), a technology that replaces flammable liquid electrolytes with stable, solid materials capable of unlocking higher energy density and enhanced safety.

But transforming these batteries from lab prototypes into mass-produced commercially available products require not only innovative materials but also precise and accurate characterization of those materials. This is where Eurofins EAG Laboratories provides world-class support to customers throughout the battery supply chain and life cycle

It was once fairly straightforward to categorize battery electrolytes by composition and structure, but battery chemistry has grown more complex in the last twenty years as new tweaks to existing electrolytes blur the lines between different families of materials. Each type of solid electrolyte brings unique strengths and challenges. Here we provide a high-level overview of the properties and recent developments for five of the most prominent groupings of SSEs.

Instead of relying on liquid electrolytes to move lithium ions, SSBs use a solid electrolyte to shuttle ions between electrodes. The electrolyte may be an amorphous glass, glass-ceramic, polycrystalline ceramic, polymer, or composite material. The SSE replaces both the flammable liquid electrolyte and the now unnecessary separator, allowing for higher energy density and potentially more compact batteries.

1. Sulfide-Based Electrolytes: Fast and Flexible

Sulfides like Li₁₀GeP₂S₁₂ (LGPS) are known for their exceptional ionic conductivity, rivaling liquid electrolytes. They’re soft and form excellent contact with electrodes, a major advantage for transfer efficiency.

However, sulfides are moisture-sensitive and can release hydrogen sulfide gas when exposed to air. To address this, researchers are turning to composite sulfides, blending them with polymers or binders to create thin, flexible films that retain performance while improving manufacturability and stability. Other approaches to mitigating this issue are under investigation, such as the use of inorganic H2S absorption additives in the electrolyte, coating the exterior of the electrolyte with a permanent Li ion-conductive superhydrophobic protection layer, and coating the electrolyte with a removable, ultrathin layer of organic amphipathic molecules.

2. Oxide-Based Electrolytes: Strong and Stable

Oxide electrolytes such as LLZO (lithium lanthanum zirconium oxide) and LAGP (lithium aluminum germanium phosphate) are prized for their thermal stability and chemical robustness. They perform well with lithium metal anodes, paving the way for higher energy densities.

Their main drawback is brittleness, which can make achieving seamless interfaces difficult. Researchers often rely on precision polishing, surface coatings, or interlayers to reduce resistance and prevent cracks, all of which depend on advanced imaging and surface characterization to ensure consistent quality

3. Halide-Based Electrolytes: The Air-Stable Contenders

A newer class, halide electrolytes such as Li3YCl6 and Li2ZrCI6, are gaining momentum thanks to their air stability and resistance to oxidation. Their crystal structures allow lithium ions to move efficiently, while being easier to process than sulfides or oxides.

An exciting discovery in the broader class of halide electrolytes is the ternary oxychloride NaCl–TaCl5–Ta2O5 first announced in 2024. Composed of NaCl and Ta2O5 particles in a Na–Ta–Cl–O amorphous matrix, this new electrolyte is claimed to exhibit high conductivity at room temperature with improved chemical and mechanical stability relative to conventional chloride electrolytes.

Halides show strong potential for high-voltage cathode compatibility and manufacturing scalability, making them a serious contender for next-generation solid-state EV batteries.

4. NASICONs and LISICONs: The Structural Innovators

An example of a classic NASICON (sodium superionic conductor) compound is Na3Zr2(SiO4)2(PO4), but lithium analogs of NASICONs (sometimes called LISICONs) also exist. Some being explored as electrolytes include lithium germanium phosphate (LGP), lithium zirconium phosphate (LZP), and lithium titanium phosphate (LTP). LISICONs offer wide electrochemical stability windows and can be fine-tuned through doping to achieve excellent conductivity. True NASICONs are also being explored as solid electrolytes for a sodium ion battery, laying out the groundwork for a more sustainable and less costly energy storage future that moves beyond lithium.

5. Polymer and Composite Electrolytes: Flexible and Process-Friendly

Solid polymer electrolytes (SPEs), typically based on polyethylene oxide (PEO) or polyacrylonitrile (PAN) doped with lithium salts, are lightweight, flexible, and easy to manufacture.

While their conductivity is lower than ceramic types at room temperature, hybrid composite electrolytes, polymers filled with ceramic nanoparticles like LLZO, combine the best of both worlds: flexibility, dendrite, suppression, and improved ionic transport.

Developing high-performance solid-state batteries isn’t just about chemistry; it’s about understanding how these materials interact on an atomic and structural level.

Even tiny impurities, grain boundary defects, or interfacial reactions can cause a battery to fail. That’s why advanced material analysis is at the heart of solid-state innovation.

At Eurofins EAG Laboratories, we specialize in uncovering these details with precision. Our scientists use state-of-the-art instrumentation to evaluate everything from raw powders to finished cells, helping clients validate performance, purity, and durability.

Raw Material Characterization and Purity Analysis

A battery’s performance is only as good as its starting materials. Even trace impurities can throw off conductivity or stability. EAG Laboratories helps clients ensure quality by offering:

Solid Electrolyte Characterization

Once materials are in powder or film form, we test them for:

Interface Analysis

The interface between electrolyte and electrode is often where the battle is won or lost. EAG Laboratories supports clients by:

Solid-state batteries are not science fiction anymore; they’re in laboratories as novel electrolyte compounds, in production as prototype batteries, and on the radar of nearly every major automaker. The potential benefits are massive: lighter electric vehicles that drive further on a charge, safer consumer electronics, and energy storage systems that make renewable power more reliable.

To get there, manufacturers need more than promising materials. They need an analytical partner that can instill confidence in the purity, stability, and performance characteristics of new battery materials as they are scaled from the lab to commercial production.

At EAG Laboratories, our goal is to give battery developers and manufacturers that necessary confidence so that they can focus on what they do best. With cutting-edge instrumentation and a team of expert scientists, we help translate materials innovation into real-world solutions. Because the sooner we can solve today’s challenges, the sooner solid-state batteries can power tomorrow.

Contact an expert today.

SEM equipped with EDS can capture detailed images and identify elements simultaneously on the surface of samples.

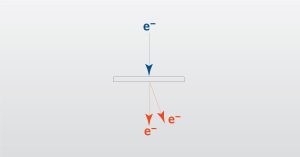

In this webinar we will introduce the principles of Transmission Electron Microscopy (TEM) with a focus on real-world problem-solving.

Part one of a four-part series on Rare Earth Elements (REEs). In Part one, we explore mining of rare earth elements and why a purity survey is needed.

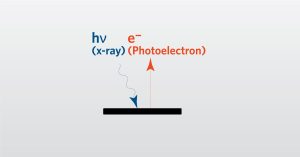

In this webinar we introduce X-Ray Photoelectron Spectroscopy (XPS) which is a surface analysis technique.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.