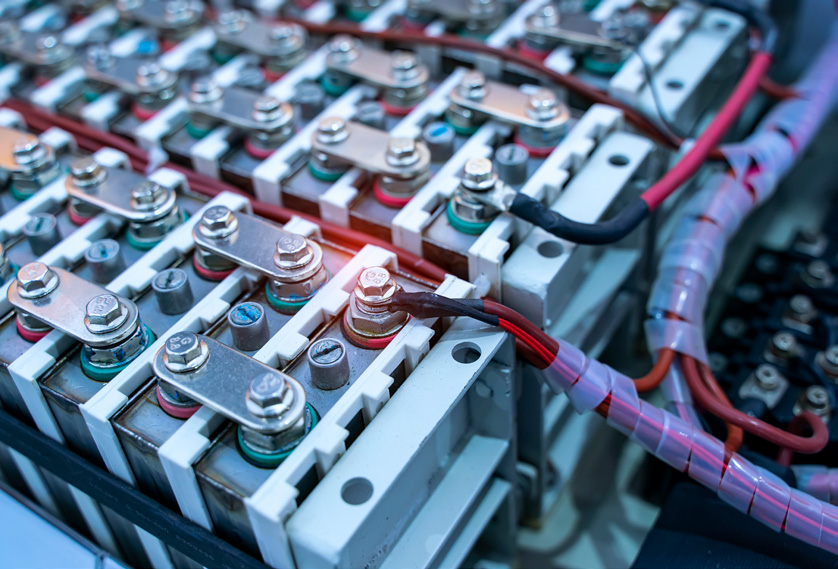

Understanding Ionic Conductivity and its Critical Role in Battery Electrolyte Performance

This application note introduces the principles of conductivity profiling using a platinum electrode probe and emphasizes its importance in battery electrolyte evaluation.