Understanding VCSELs: From Epitaxial Wafer Growth to Failure Analysis

Home » Understanding VCSELs: From Epitaxial Wafer Growth to Failure Analysis

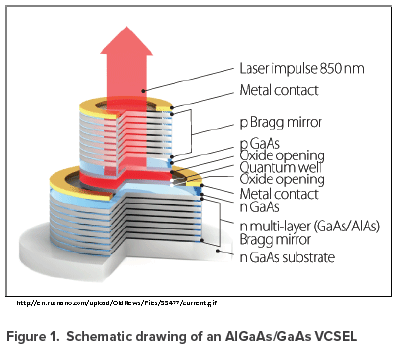

The vertical cavity surface emitting laser (VCSEL) has several advantages over its edge-emitting cousin. Its strengths include a higher modulation speed, on-wafer testing and the emission of a symmetrical emission pattern that is oriented perpendicular to the surface. This form of emission is ideal for coupling into other optical components.

This emission pattern is also well suited for configuring multiple devices into a two-dimensional array. However, all these merits over edge-emitting lasers come at the expense of a more complex device architecture.

With a VCSEL, resonator mirrors have to fulfil two roles: like an edge-emitter, they have to control the extent of optical feedback and light output; but in addition, they also have to be electrically conducting, so that they can allow the injection of carriers from the contacts into the active region.

This set of requirements is often met by forming a stack of semiconductor layers, which have thicknesses that are carefully chosen to create a distributed Bragg reflector (DBR).

To produce a high performance VCSEL, the DBR is formed from alternating layers with a sufficiently high refractive index contrast in order to realize high levels of reflection. Engineers must also ensure that the conductivity of the mirrors is sufficiently high to prevent current injection into the active region from causing excessive ohmic heating.

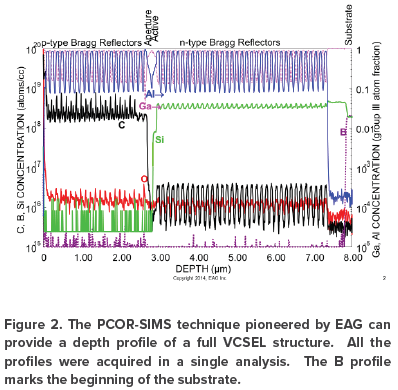

Our development of advanced techniques for materials analysis has allowed EAG Laboratories to provide comprehensive process development and failure analysis of vertical cavity surface emitting lasers.

Our proprietary PCOR-SIMS capabilities have opened up this technique so that it is no longer limited to impurity and dopant analyses of semiconductor materials.

Would you like to learn more about Understanding VCSELs?

Contact us today for your VCSEL epitaxial wafer failure analysis needs. Please complete the form below to have an EAG expert contact you.