The Battle Against Contamination: Challenges in Superalloy Manufacturing

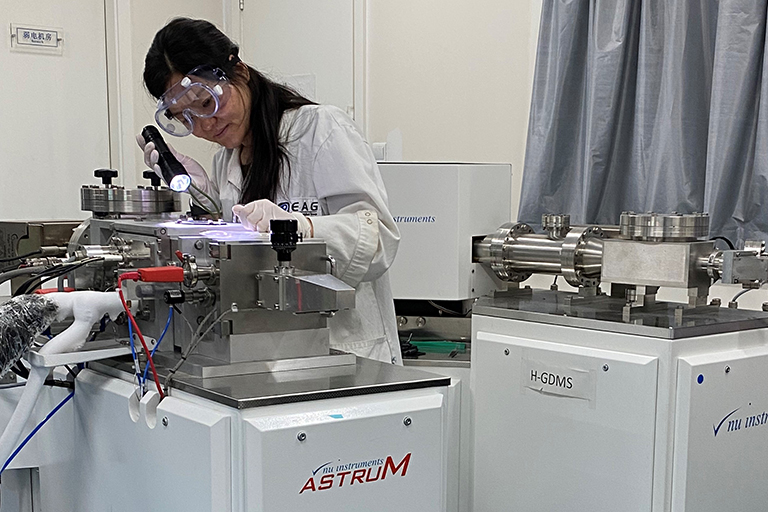

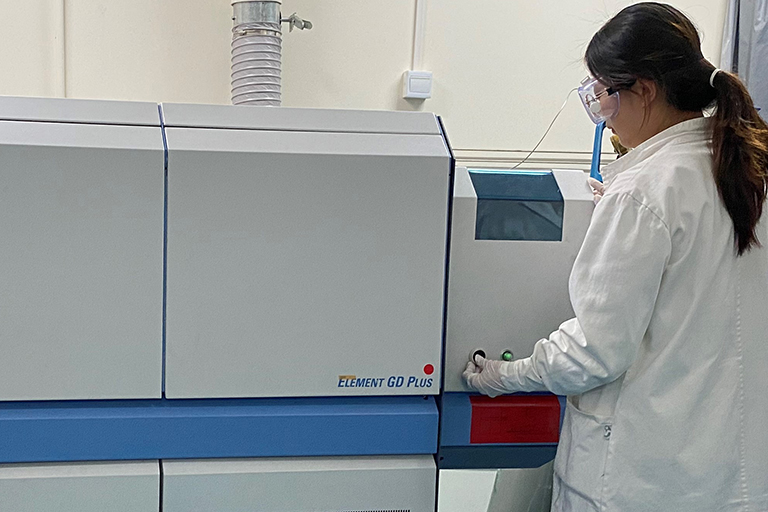

The Battle Against Contamination: Challenges in Superalloy Manufacturing Superalloys are the unsung heroes of high-performanceindustries: jet engines, gas turbines, and even nuclear reactors. However, for all their strength and thermal