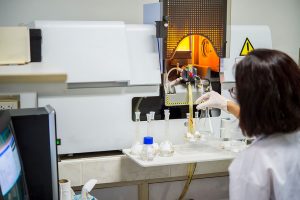

Understanding Flame Atomic Absorption Spectroscopy (FAAS)

Flame Atomic Absorption Spectroscopy (FAAS) continues to play an important role in routine elemental analysis, even as laboratories have widely adopted Inductively Coupled Plasma-based instruments. FAAS might just be the right technique for you.