Hydrogen, Carbon, Oxygen and Iron Contamination Measurements in ALD Films

Home » Hydrogen, Carbon, Oxygen and Iron Contamination Measurements in ALD Films using XPS and SIMS

ALD for semiconductors can produce films that are high in H, C, O and metals. XPS and SIMS depth profile analysis for composition & purity.

CONTAMINATION IN ALD FOR SEMICONDUCTORS

- ALD can produce films that are high in H, C, O and metals.

- High levels of H, C, O and metals are not desirable in most semiconductor films.

- Improved plasma sources reduce contamination in nitride based ALD grown films [1].

- XPS is commonly used for accurate composition profiles. However for H, C and O concentrations of 5 at% or less then XPS becomes background limited.

- SIMS analysis is required for accurate H, C and O profiles 5 at%and lower.

- Trace metals such as Fe can be measured down to 1E15 at/cm3 .

XPS DEPTH PROFILING

Composition Depth Profiles

Photoelectron emission intensity has very little dependence on surface chemistry. Intensity is dependent mostly on surface concentrations. Thus XPS is known to provide very good quantitative composition measurements. Depth profiles are done by alternating sputter etching of the surface with analysis cycles.

The result is concentration vs. depth profiles with good quantification regardless of the material. However in some materials preferential sputtering of one element over another can alter the original composition.

XPS for Composition in ALD Films

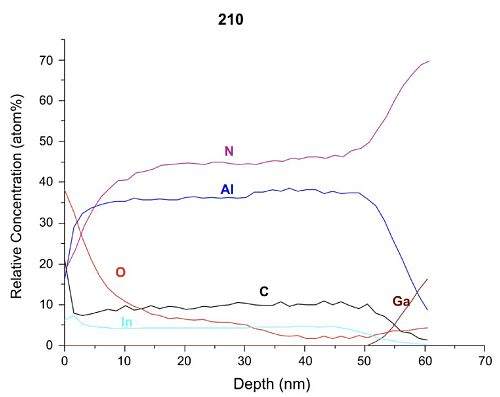

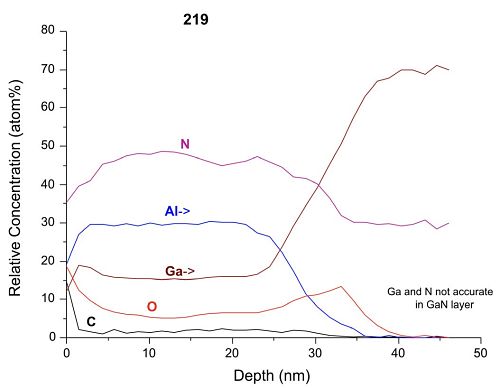

- Composition profiles for Sample 210 will have good accuracy for In, Al and N. The profile at the surface showing oxygen displacing nitrogen is likely real.

- Sample 219 shows an uneven distribution of N through the AlGaN layer. The substrate GaN is not quantified due to a spectral interference.

XPS for Carbon and Oxygen in ALD Films

- ALD films tend to incorporate relatively high levels of H, C and O during growth.

- ALD film composition is commonly measured by XPS due to its inherently quantitative nature. Thus C and O profiles by XPS are often seen.

- XPS has high C and O backgrounds. Levels of 10 at% are probably real, levels of 5 at% might be real, and 2-3 at% is probably background.

- Sample 210 shows C at 10 at% and O at 2 to 6 at% – C is real and O is background.

- Sample 219 shows C at 2 at% and O 6 to 8 at% – both C and O are strongly affected by background.

TECHNIQUES FOR ALD ANALYSIS

XPS (X-ray Photoelectron Spectroscopy)

- XPS provides survey analysis capability for elements Li through U

- Binding energy measurements provide oxidation state information

- Depth profiles are inherently quantitative, subject to preferential sputtering effects

SIMS (Secondary Ion Mass Spectrometry)

- SIMS can detect every element in the periodic table including H with ppm to ppt detection limits.

- Depth profiles show layer structure, dopants and contaminants.

- Layers from 1.2 nm to 10 µm can be profiled.

SIMS DEPTH PROFILING

Trace Element Depth Profiles

SIMS has ppm to ppt detection limits for every element in the periodic table including H. A primary ion beam sputter etches the sample surface, both generating ions from the sample material that can be mass analyzed to determine the element.

Sputter etching forms a crater enabling sampling with depth. SIMS quantification depends on standards. The standard must have the elements of interest in the same matrix material. Quantification is generally valid from 1 at% to trace level.

SIMS for Carbon and Oxygen in ALD Films

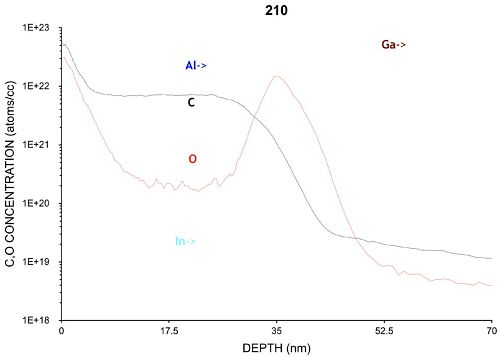

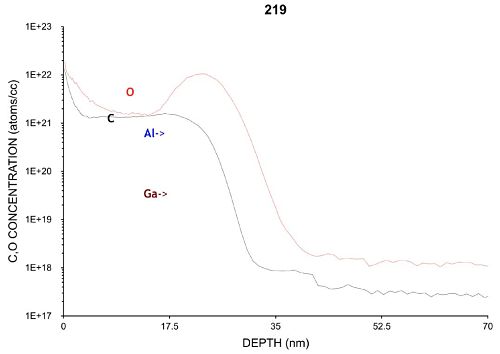

- SIMS combines high depth resolution for thin films with very good detection limits for H, C and O making SIMS a very good choice for ALD contaminant depth profiling.

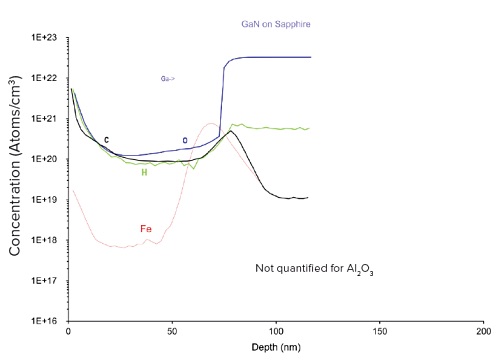

- Detection limit for H is 1E17 at/cm3. Detection limit for C is 2E15 at/cm3. Detection limit for O is 1E15 at/cm3.

- Detection limits for H, C and O are very good due to good vacuum systems, high sputter rates, and good sensitivity for these elements.

- Concentrations of C and O reported in Samples 210 and 219 are well above background.

SIMS for Composition in ALD Films

- EAG has developed a protocol called ‘PCOR-SIMS’. We use the SIMS measurement itself to measure layer composition.

- We measure composition so we can use the correct sensitivity factors for the dopant or contaminant being measured.

- We measure composition at every data point allowing us to use the correct sensitivity factor at every data point. The result is point-by-point correct SIMS – or PCOR-SIMS.

H, C, O, and Fe Profiles by SIMS

- H, C and O can be measured together with very good depth resolution and very good detection limits.

- Trace metal profiles require a separate measurement. The profile seen here is an overlay.

- The choice of metal to profile depends on the deposition equipment and precursor gases used.

SOURCES OF BACKGROUND IN ALD ANALYSIS

Background from H, C, N and O comes from the residual gas in the instrument vacuum system. Gas arrives at the sample surface and the likely-hood of sticking to the surface depends on the gas, the sample material and the condition of the surface. A freshly sputtered surface increases the likely-hood of the gas sticking.

XPS Background

In XPS depth profiling, the surface is sputter etched, sputtering stops, and the analysis cycle begins. During the analysis cycle, gas from the vacuum has a chance to accumulate on the surface.

SIMS Background

In dynamic SIMS (except for TOF), the surface is continuously sputtered and thus background is a balance between residual gas arrival rate and sample sputter rate. The sample sputter rate is much higher than the residual gas arrival rate and thus dynamic SIMS background is several orders of magnitude lower than XPS.

DISCUSSION

The Choice of XPS for Depth Profile Analysis

- For film composition, XPS is a good choice. Elemental quantification is the same, regardless of the material, so quantification accuracy is good in all materials. However one must be careful of preferential sputtering where one element is removed preferentially over another, changing the surface composition.

- For atmospheric elements C and O, XPS can provide good quantification accuracy for concentrations down to 10 at%. At lower concentrations, instrumental background begins to affect the measurement.

The Choice of SIMS for Depth Profile Analysis

- For atmospheric elements H, C and O, SIMS can provide excellent detection limits. Background is not an issue for accurate profiles in ALD.

- Metal impurities can be profiled and accurately quantified.

- For film composition, SIMS can provide quantification when the material system has been calibrated with standards.

- Very thin films can be profiled using high depth resolution protocols. 2nm films and even less can be profiled extracting real distribution information.

REFERENCES

[1] C. Ozgit-Akgun, E. Goldenberg, A. Kemal Okyay and N. Biyikli, J. Mater. Chem. C 2 (2014) 2123.

Would you like to learn more about Contamination Measurements in ALD Films?

Contact us today for your contamination measurement in ALD film needs. Please complete the form below to have an EAG expert contact you.