Medical Device Electronics: Improving Reliability with Auger Electron Spectroscopy

Home » Medical Device Electronics: Improving Reliability with Auger Electron Spectroscopy

Advanced electronics are pervasive in today’s medical devices, from hearing aids to heart pacemakers and defibrillators. Reliable electronics performance is essential for the proper functioning of these critical devices. One aspect of the electronic circuitry that is sometimes problematic involves the integrity of wire or ball bonding to the metallic bond pads. Contamination and/or the presence of relatively thick oxide layers on bond pad surfaces can lead to poor adhesion and electrical connectivity of the wire or ball to the bond pad.

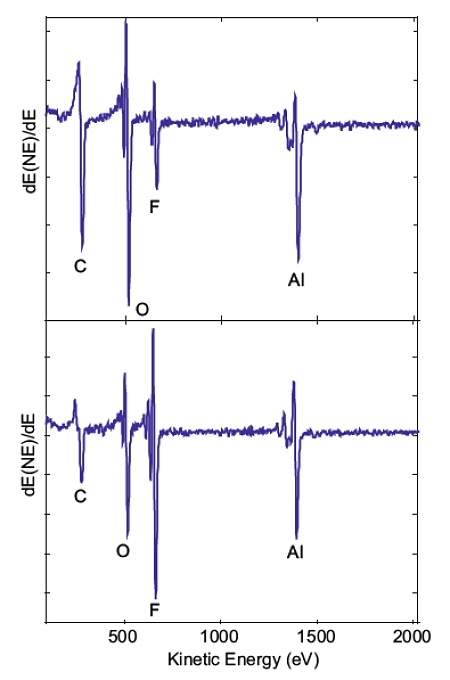

The source of such bonding problems can be readily identified via Auger Electron Spectroscopy (AES) analysis. AES can be used effectively to monitor the cleanliness of the outermost surface of bond pads, as well as measure the thickness of the oxide layer thus identifying the probable cause of bonding problems Figures 1a and 1b show AES spectra from good and poor-performing bond pads, respectively. The failed bond pads gave poor bond strengths during adhesion testing. The Auger data show a much larger concentration of fluorine contamination on the surface of the bad pad. These results led to a search for sources of fluorine contamination which was found on a foam material used to separate samples at the wafer level.

In Figure 1 the top graph shows the Survey Spectrum from a normal Bond Pad

In Figure 1 the lower graph shows the Survey Spectrum from a failed Bond Pad

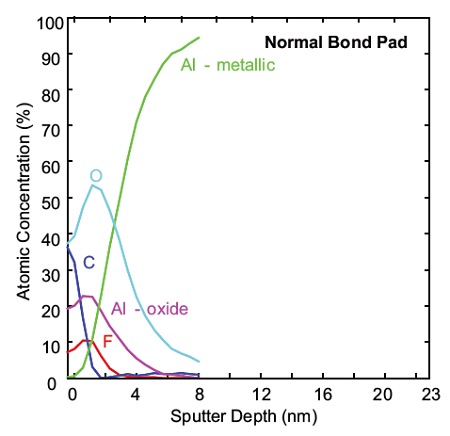

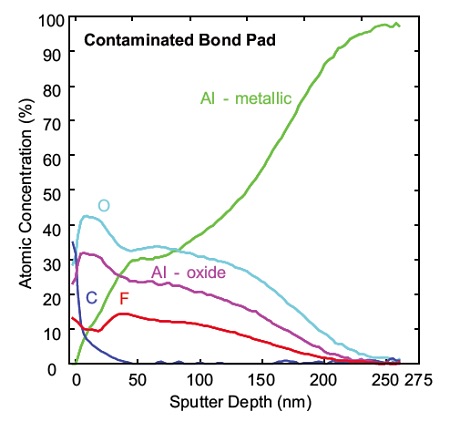

In addition to the fluorine surface contamination, Auger depth profiles shown in Figures 2a and 2b reveal that the oxide layer is much thicker on the poor-performing pad compared to the good pad. Fluorine is detected throughout the oxide layer, indicating that the oxidation of the pad is catalyzed by the fluorine contamination.

Would you like to learn more about Medical Device Electronics Reliability?

Contact us today for your medical device electronic reliability needs. Please complete the form below to have an EAG expert contact you.