Overview

EAG Laboratories is a world leader in failure analysis services. We support customers by investigating the root cause of a material failure, and can act as an expert witness in a legal investigation to determine who is at fault in a liability case. From raw materials to the end product, we offer a comprehensive suite of testing techniques to determine a materials failure.

What is Failure Analysis?

Failure analysis uses data to determine the root cause of a failure using various analytical techniques. Firstly, the investigation typically involves testing failed components to determine the area of the breakage. Secondly, further analysis is used to identify potential reason for the failure to occur. Nondestructive testing methods are sometimes utilized at the early stages of a failure investigation to allow for more tests to be made on a material.

Failure Analysis Services at EAG

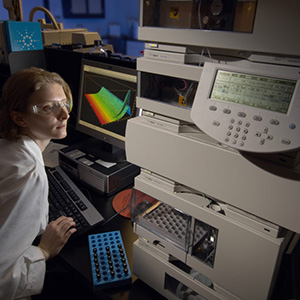

Failure Analysis requires the right combination of tools, methodology, and experience to understand the problem, and identify the failure mechanism. EAG Laboratories has several hundred highly educated and experienced employees working on 2,500 instruments in 22 laboratories around the world. Our integrated model supports companies during the complete product lifecycle from conception to volume production in a IP Secured environment.

The following are just a few of our services that can help you understand the root cause of your failure.

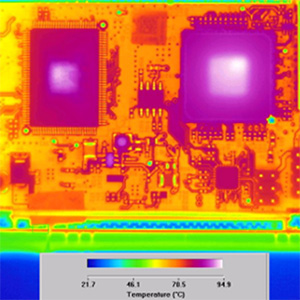

Providing failure analysis services for the electronics industry for devices such as ASIC, image sensors, discretes, passives, RF, MEMS, MOSFETs, medical device assemblies, PCBs, 3D packages, Advanced CMOS, III-V, GaAs, laser diodes, LEDs, and solar cells.

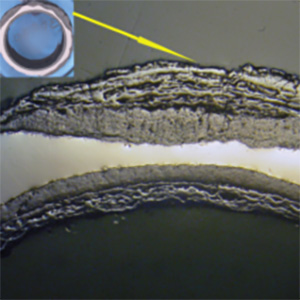

Failure and product improvement of metal components in industries such as aircraft, aerospace, transportation, construction, consumer products, electronics, hostile service environments, energy production, structural components and medical devices.

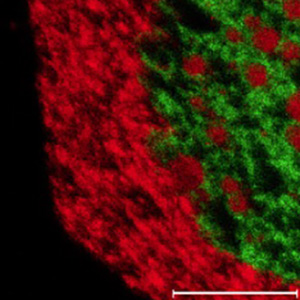

Investigating failures due to contamination issues originating from incoming raw materials, supply chain problems or manufacturing processes.

Identifying surface chemistry failures due to adhesion, bonding, cleanliness, morphology and topography of a material.

Identifying failures in polymers using physical and chemical analysis to determine issues such as material incapability.

Analysis to determine if the presence of any transferred chemicals are skin sensitizers causing toxic, allergenic or abrasion concerns.

Would you like to learn more about complete range of Failure Analysis services?

Contact us today for your complete range of Failure Analysis services needs. Please complete the form below to have an EAG expert contact you.