Product Reliability Test of a Bluetooth Speaker

Home » Product Reliability Test of a Bluetooth Speaker

EAG has established product reliability test processes. In this example we inspect a Bluetooth speaker using Accelerated Testing.

Reliability Test Approach

Test plan definition (define CtQ & pass-fail criteria) => experimental phase => data analysis

Product Reliability Test Example

Reliability of a Bluetooth speaker

Test Plan Definition — Accelerated Testing

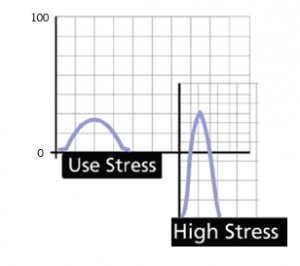

Exploratory experiments from field data showed that this speaker is sensitive

to mechanical forces (dropping) and to the combination of humidity and high

temperature when switched on

Test Plan

Non-operational drop tests at 3 heights and operational damp-heat storage tests at 3 heights

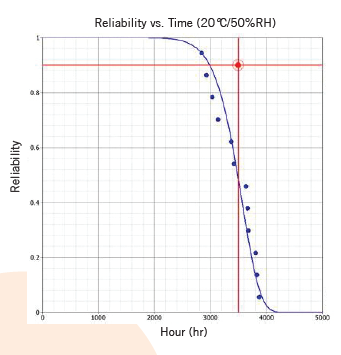

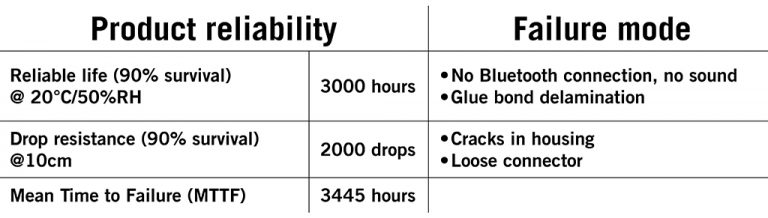

Experimental Phase & Data Analysis

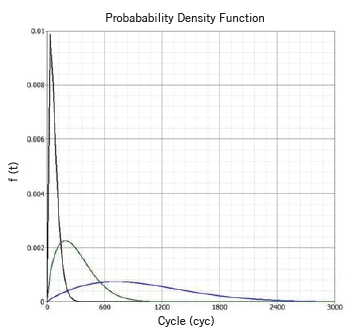

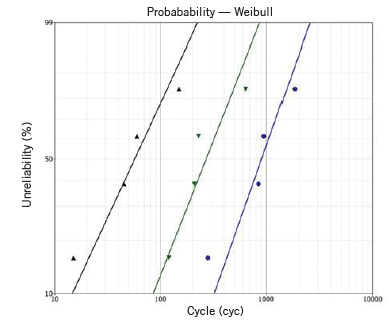

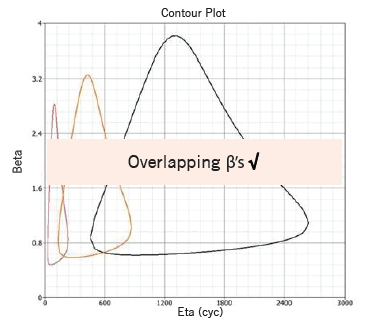

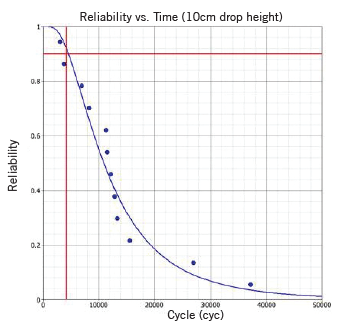

Drop test 30 – 60 – 100 cm

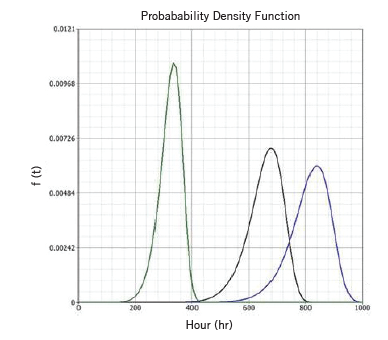

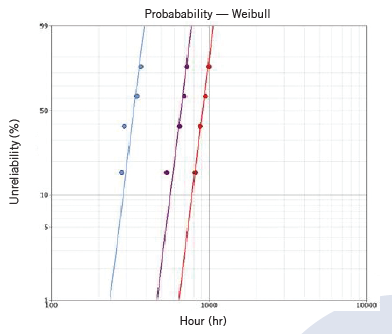

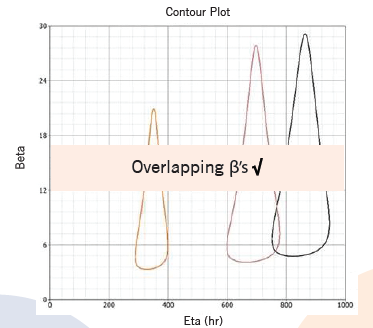

Damp-heat test 40°C/90%RH – 50°C/50%RH – 60°C/90%RH

Results

Material & Component Reliability Testing

Same approach as for product testing. Often no clear pass/fail criteria available because of progressive degradation

- Failure mode(s) and degradation data needed (chemical, optical, physical. mechanical) for correct data analysis

- Our own Material Analysis Lab is well equipped to support failure mode and degradation studies

Would you like to learn more about Product Reliability Testing?

Contact us today for your product reliability testing needs. Please complete the form below to have an EAG expert contact you.