Scanning Acoustic Microscopy (SAM)

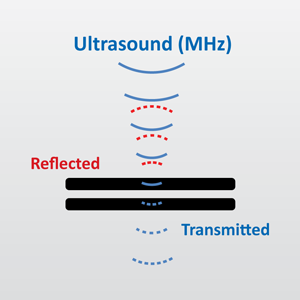

Scanning Acoustic Microscopy (SAM) uses sound waves to detect and identify internal delamination, voids, material density changes, defects and many other anomalies within devices, assemblies and materials.

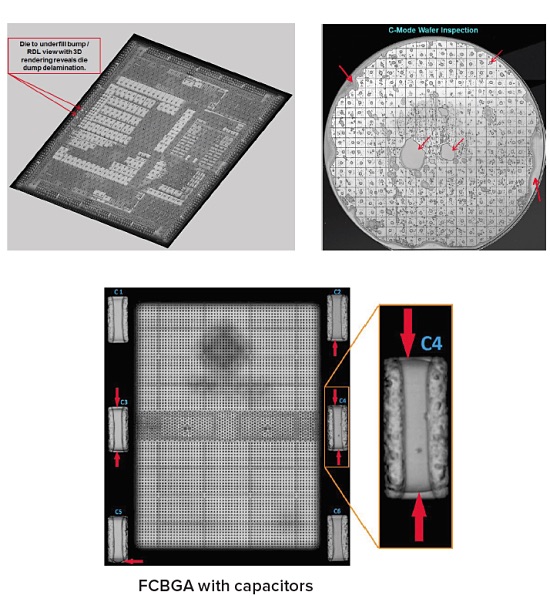

SAM is highly sensitive to the presence of delamination and material density variations, which are difficult to detect using X-ray radiography, infrared imaging and other non-destructive techniques. It can detect sub-micron air gaps and has a defect resolution of ~5 µm.

EAG offers various imaging modes, allowing the operator to gain the optimal viewing perspective based on the orientation of the feature within the sample. In addition, EAG’s SAM systems incorporate advanced software, hardware features and a wide variety of transducers, which allows EAG to provide our customers with the best imaging on the market.

IDEAL USES of SAM AND KEY FAILURE MECHANISMS

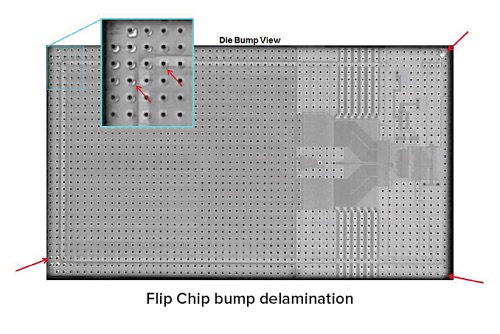

- Interfacial delamination

- Joint, bonding and seal analysis

- Void detection

- Crack detection – wafer, die and package level

- Printed circuit board anomalies

- Imaging adhesion in films, brazing, soldering and other interfaces

KEY INSPECTION APPLICATIONS

- Failure analysis

- Product reliability

- IPC / JEDEC J-STD-020 (required for MSL classification)

- Mil-STD 883, Method 2030, Method 2035

- NASA, PEM-INST-001

- Chip Scale Package (CSP) inspection

- Stacked die imaging

- Plastic-encapsulated IC inspection

- Process validation

- Vendor qualification

- Product inspection

- Quality control

- Research and development

- Counterfeit detection

Strengths

- Non-destructive inspection

- Submicron delamination detectability (<0.2 μm)

- Wide range of low to ultra-high transducer frequency and focal lengths for optimal penetration and resolution imaging for a variety of materials and samples

Limitations

- Samples submerged in deionized water

- Tall, very large or irregularly shaped samples. Planar construction samples work best

- Reduced imaging through multiple layers/interfaces, particularly soft or porous materials and sound scattering due to non-planar interfaces, features and roughness (e.g. angled facets)

SAM Technical Specifications

- A, B and C mode scans

- SALI (Scanning Acoustic Layer Imaging)

- Pulse echo/reflection and through transmission

- Industry spec and standards supported

- IPC/JEDEC, J-STD-020, J-STD-035

- Mil-STD 883, Method 2030, Method 2035

- NASA, PEM-INST-001

Would you like to learn more about using Scanning Acoustic Microscopy (SAM)?

Contact us today for your Scanning Acoustic Microscopy (SAM) needs. Please complete the form below to have an EAG expert contact you.