Dye & Pry Webinar

In this webinar we introduce Dye and Pry that involves cleaning a sample to remove debris & flux around solder, then exposing it to a red dye.

Home » Detecting the Invisible: How Full Survey Chemical Analysis Prevents Aerospace Failures

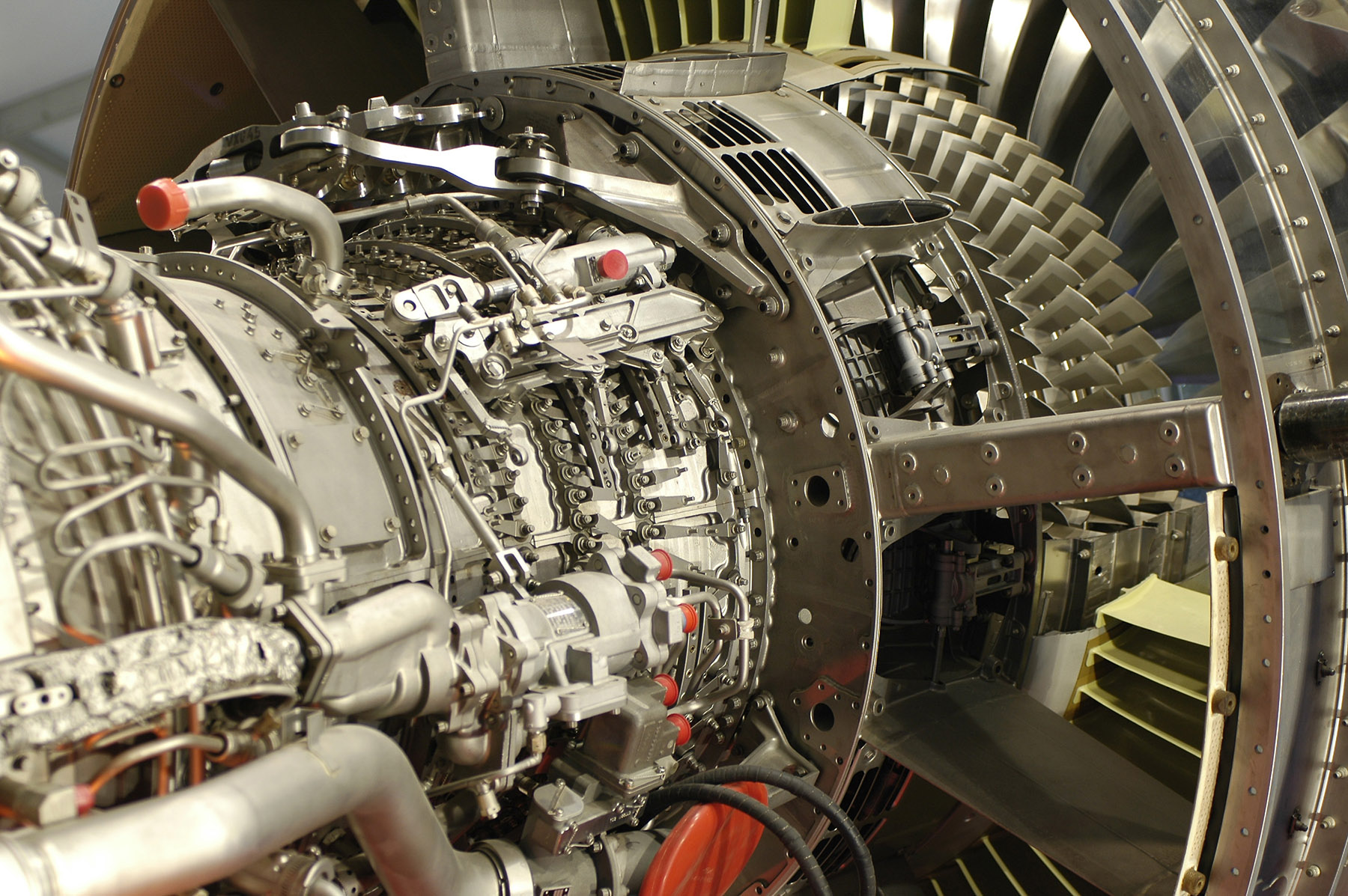

In the high-stakes world of aerospace engineering, some of the most dangerous threats to a mission aren’t visible to the naked eye. While designers focus on aerodynamics, weight, and strength, a silent risk lurks beneath the surface: chemical impurities. Fortunately, one analytical tool is available as a linchpin in stopping these failures before they start: Glow Discharge Mass Spectrometry (GDMS).

GDMS is uniquely capable of detecting elemental impurities at ultra-trace levels, making it an essential tool for verifying material purity in everything from jet engine turbine blades to spacecraft fasteners. GDMS is helping the aerospace industry detect the invisible and prevent irreversible damage.

Glow Discharge Mass Spectrometry is one of the most sensitive and comprehensive full-survey analytical techniques for evaluating the elemental composition of metallic as well as non-metallic solids. Its unique capabilities make it the gold standard in aerospace materials testing:

Unlike techniques that only provide surface-level data or require dissolution of the sample, GDMS offers direct solid analysis with minimal matrix effects. This makes it ideal for high-purity materials like superalloys, refractory metals and alloys, titanium alloys, aluminum-lithium or aluminum-scandium systems, ceramics and composites used in demanding aerospace applications.

While most people assume that GDMS only looks at bulk conductive solids, it also plays a role in:

In short, wherever purity matters in aerospace, GDMS is becoming the go-to solution for full-spectrum elemental insight.

Aerospace materials must meet extreme performance demands, but those demands can be undone by undetected contaminants at trace and ultra-trace levels. Glow Discharge Mass Spectrometry stands at the front line of defense, detecting elemental impurities early in the production cycle, long before they become failure points.

At EAG Laboratories, our scientists worldwide bring decades of specialized experience in high-precision GDMS analysis tailored to the aerospace industry. From qualifying a new titanium billet, validating 3D-printed components, or seeking certification for space-grade alloys, our team provides rigorous trace element analysis for your materials demand. We work closely with clients to interpret results, troubleshoot unexpected contaminants, and ensure every component meets the utmost purity standards.

As aerospace technologies evolve toward hypersonic aircrafts, and lighter, stronger materials, purity control by GDMS will only become more essential. In the mission to reach higher, go farther, and stay safe, GDMS helps us see what others can’t and protect what matters most. When failure is not an option, EAG Laboratories delivers certainty you can launch with.

In this webinar we introduce Dye and Pry that involves cleaning a sample to remove debris & flux around solder, then exposing it to a red dye.

The Dual Beam FIB-SEM integrates a focused ion beam with a scanning electron microscope for simultaneous sample prepping and imaging.

During this Ask the Expert webinar, our team of battery materials experts will address your pre-submitted questions during the event, as well as present about our new battery lab’s capabilities.

The roughness of a surface and how it interacts with surrounding materials and elements can have a significant impact on material technology and its functionality.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.