Multiscale investigations of Lithium Ion Battery Webinar

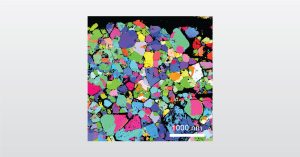

In this webinar we introduce analytical techniques for the characterization of Li-ion battery electrode (cathode) at different length scale

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.