Instrumental Gas Analysis (IGA) Services

Home » Instrumental Gas Analysis (IGA) Services

Instrumental Gas Analysis (IGA) measures mass fractions of gas-forming elements (C, H, O, N andS) present in samples from ppm to weight percentage levels. A high-temperature furnace is used to rapidly heat the sample under a flowing gaseous stream and releasing above elements from the sample for detection on a variety of detectors.

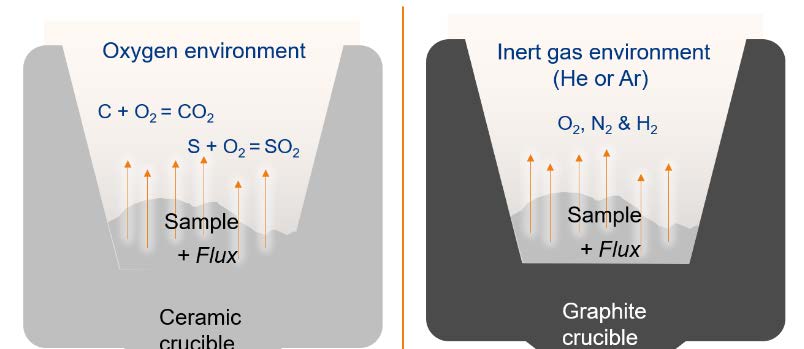

Carbon and sulfur are measured based on combustion and infrared detection. The analytical method is based on the complete oxidation of the solid sample by combustion in an oxygen plasma. The sample is placed in a ceramic crucible in a high frequency induction furnace where it is combusted.

The combustion of the sample releases various gases, which are measured by infrared detectors. The sulfur content of the sample is determined by analyzing the SO2. The carbon content is evaluated from analyzing CO and CO2 gases released from the sample.

Carbon fibers are made from acrylic fiber, which contains approximately 68% carbon. After carbonization and graphitization, carbon fibers are made with high elasticity. Therefore, the elasticity of carbon fiber depends on the carbon percentage in the carbon fiber. For example, fibers with standard elasticity have 90% or more carbon with nitrogen as the secondary element. Determination of carbon weight% therefore becomes essential to verify the quality of carbon fiber and a high precision method is used for measurement as opposed to the standard method.

IGA testing can be divided into two major categories: the well-established testing where standard ASTM test methods are used to analyze conventional samples (e.g., steel, titanium alloys, and refractory metals) and client-specific testing methods for unconventional samples (e.g., non-porous samples, battery electrodes) developed by highly experienced scientists going beyond standardized ASTM test methods. At Eurofins EAG, four state-of-the-art laboratories provide fast, accurate IGA services worldwide. Our Syracuse, NY, Toulouse, France, Eindhoven, Netherlands, and Shanghai, China facilities are operating daily under our well monitored quality systems.

Would you like to learn more about Instrumental Gas Analysis (IGA) Services?

Contact us today for your Instrumental Gas Analysis (IGA) needs. Please complete the form below to have an EAG expert contact you.