Optical Profilometry Roughness Measurements on Machined Parts

Home » Optical Profilometry Roughness Measurements on Machined Parts

Surface topography affects the appearance, functionality, and performance of a material, which makes it a critical consideration for materials science in a wide range of industries. For example, on a macroscopic scale topography can dictate if a surface appears shiny or matte; or it can determine if a mechanical seal is airtight or if it leaks. In particular, precision machining often requires stringent control of surface topography to meet industry-driven roughness specifications or standards.

Common machining processes include milling, grinding, lapping, reaming, and turning. These processes utilize different machines and approaches to controllably remove material from a piece of raw material and create a part with the desired shape, finish and function.

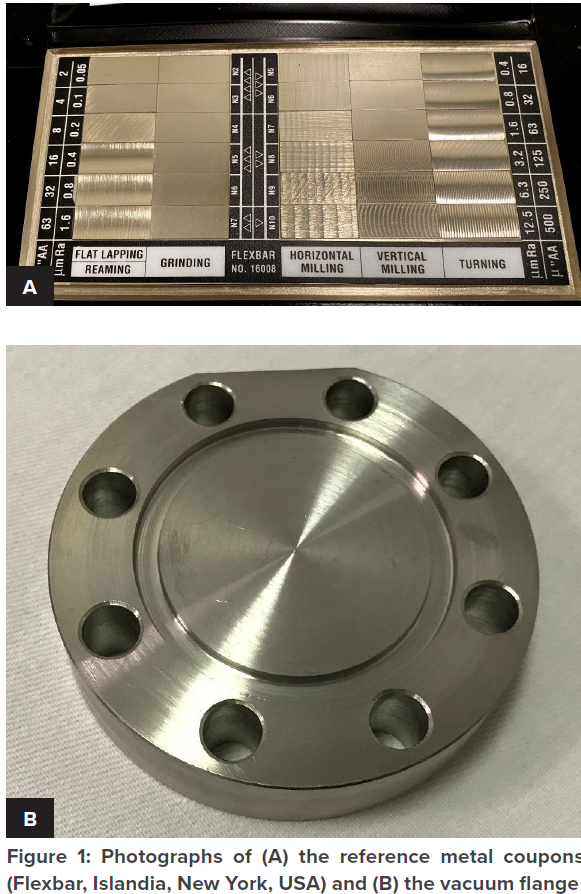

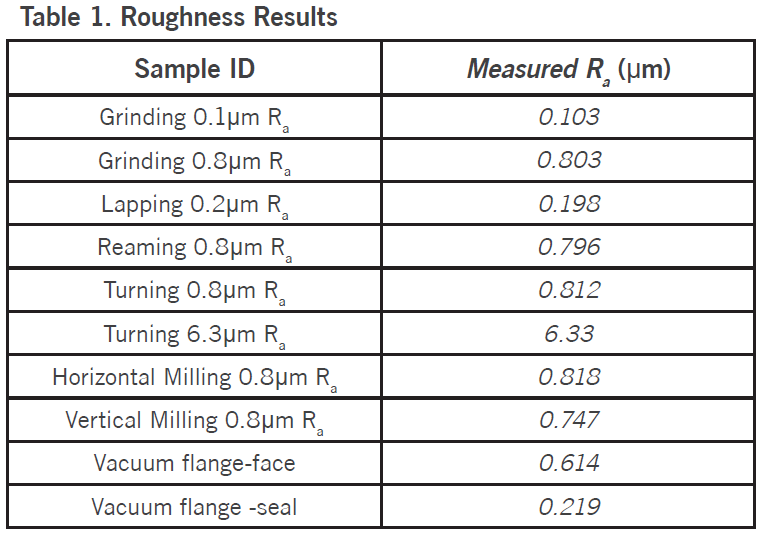

Characterizing surface topography is possible with a technique called Optical Profilometry (OP), which is also known as White Light Interferometry (WLI). In this application note, OP is used to measure the roughness of reference coupons (Flexbar, Islandia, New York, USA) that were machined in various ways to different roughness specifications. Additionally, the surface finish of a vacuum flange is determined as an example of characterizing the topography of an unknown sample.

In this application note, Optical Profilometry is used to measure the roughness of reference coupons (Flexbar, Islandia, New York, USA) that were machined in various ways to different roughness specifications.

Additionally, the surface finish of a vacuum flange is determined as an example of characterizing the topography of an unknown sample.

Roughness Results

Would you like to learn more about Roughness Measurements on Machined Parts?

Contact us today for your roughness measurements on machined part needs. Please complete the form below to have an EAG expert contact you.