Evolved Gas Analysis (EGA)

EGA is a method for monitoring small amounts of gas molecules evolved from samples when heated above room temperature. This analysis can be primarily used to determine: (1) composition of evolved gases (2) concentration of evolved gases (3) evolution profile with respect to heating temperature. This information is vital for quality control, failure analysis or establishing protocol for a manufacturing process.

At EAG Laboratories, we are successfully using evolved gas analysis for a variety of samples providing solutions to different industries including semiconductors, aerospace and defense, coatings and adhesives, energy storage and batteries and medical devices.

What is Evolved Gas Analysis (EGA)?

Principle

Gas molecules evolve from a surface/solids/powders when heated above room temperature. In the EGA method, a sample is evacuated to minimize the gas from surroundings. When the vacuum reaches a background level, the sample is heated and evolved gases are then expanded to mass spectrometer volume. Using a thoria coated iridium filament, gases are ionized to facilitate mass separation using a quadrupole mass analyzer. Positive ion currents are measured using an electron multiplier, providing intensity of each gas released from sample.

Common Applications

- Comparative study: Good vs. Bad samples

- Wafer level failure analysis for hermetic electronic components

- Confirming quality of UHV grade cleaning for SS parts

- Comparative study for gas release at a specific temperature

- Direct Gas analysis

- Outgassing from gas tight seals in hermetic devices

- Efficacy of getter inside a vacuum cavity

- Outgassing rates (moles/cm2/sec)

- Gas released in cavity after outgassing (piercing in vacuum)

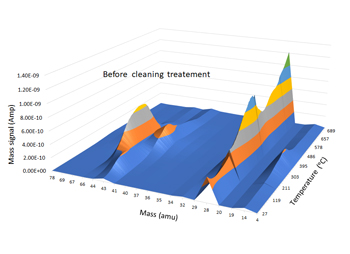

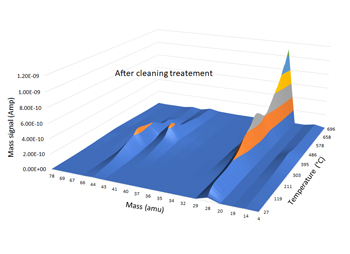

Qualitative scan

- Mass scanning while ramping temperature

- 3-D plotting of Temperature-vs-mass-vs-signal

- Comparative scan: Good vs. Bad samples

3-D representation showing mass release signals for different masses with respect to outgassing temperature. The comparison between chemically treated and untreated Si wafer clearly shows the effect of cleaning treatment. Higher release for mass 44 (e.g., CO2) and mass 28 (e.g., N2/CO) is observed for untreated sample.

Ideal Uses of EGA

- Surveying gas species in solid and gas samples

- Profiling gas release with respect to temperature

- Failure analysis for hermetic packages

- Outgassing rates for metals and cleanliness investigations

Strengths

- Any gas species from 1 to 200 atomic mass unit (amu) can be surveyed under ultra-high vacuum (~ 10-9 Torr)

- Flexible sampling fixtures to accommodate various types of samples (solids, powders and gas)

- High heating range: 24°C to 1000 °C, with heating rate as low as 0.01 °C/minute

Limitations

- Moderate detection limit

- Most analyses are project based unlike standard routine analysis

EGA Technical Specifications

- Signals detected: ion current measurement for mass resolved positive ions using quadrupole mass spectrometer

- Mass range: 1 to 200 atomic mass unit (amu)

- Detection limit: ~1000 parts per million (ppm)

Would you like to learn more about using Evolved Gas Analysis (EGA)?

Contact us today for your Evolved Gas Analysis (EGA) needs. Please complete the form below to have an EAG expert contact you.