In the Lab: Got Cracks?

Join us “In the Lab” to learn how investigative analytical chemistry can help solve your product or manufacturing line problems!

Home » How Ion-TOF SIMS Uncovers Hidden Layers in Semiconductors

If you cracked open a semiconductor chip and looked inside, you might expect to see neat layers stacked like a sandwich. In a way, that’s true, but the “layers” we’re taking about are so small that they’re measured in nanometers, thousands of times smaller than a human hair.

These ultrathin layers are what make our phones faster, our computers smarter, and our sensors more precise. But here’s the challenge: how do you actually see what’s happening inside such tiny structures without destroying the whole device?

That’s where depth profiling with time-of-flight secondary ion mass spectrometry (TOF-SIMS) comes in. It’s like peeling back the layers of a semiconductor, atom by atom, and taking a chemical fingerprint of each one along the way.

Think of TOF-SIMS as a very precise “nano-shovel.” A focused ion beam gently sputters away the material, layer by layer. As each layer is removed, another beam analyzes the exposed surface, identifying what elements or molecules there are.

The result? A layer-by-layer composition map of your device, showing exactly where dopants are, how sharp the interfaces look, and whether any unwanted contaminants are lurking between layers.

Semiconductor devices live or die by the details. Here’s why depth profiling matters:

Depth profiling helps engineers see below the surface to confirm that every layer is exactly where it should be.

The semiconductor world is not just about silicon anymore. Today’s devices rely on a variety of advanced materials, each with unique structures and challenges:

In materials like GaN, TOF-SIMS depth profiling is valuable. Engineers can detect dopant distributions with nanometer precision, verify the sharpness of heterostructure interfaces (such as GaN/AIGaN junctions in high-electron-mobility transistors), and identify unwanted impurities that might reduce performance or yield.

Take a silicon-based transistor gate stack as an example. You have the following:

With TOF-SIMS, If the transition between layers looks blurred, you know there’s diffusion happening. If a surprise signal shows up (like sodium), you have just uncovered a contaminant.

The same principle applies to GaN devices, where depth profiling reveals whether aluminum, gallium, and nitrogen signals remail sharp at interfaces, or whether unwanted oxygen or carbon sneaks in during fabrication.

Other techniques can give you a sense of composition, but TOF-SIMS has some major advantages:

It’s basically a microscope for chemistry, designed to explore invisible layers that define the future of microelectronics, from traditional silicon chips to next-generation GaN and SiC power devices.

The insights provided by TOF-SIMS go far beyond curiosity. They have a direct power within the semiconductor industry:

You might not think about what’s inside your phone, laptop, or car, but semiconductor design affects your life in big and small ways. TOF-SIMS depth profiling supports:

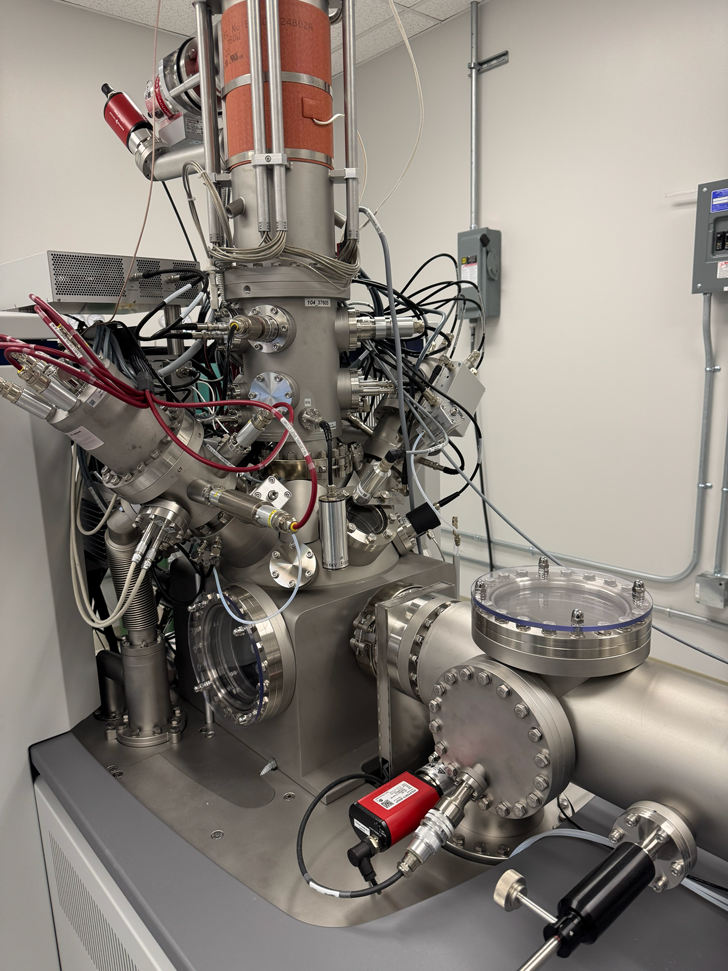

At EAG Laboratories, our focus is on helping clients make sense of complex materials data. We’ve equipped our state-of-the-art laboratory with the latest SIMS and TOF-SIMS instruments, including newly installed systems that deliver industry-leading depth resolution and sensitivity. This ensures we can help capture precise chemical profiles even in the most advanced semiconductor structures.

Our strength also lies in interpreting results with scientific rigor. Our team of internationally recognized scientists have experience working with silicon, GaN, SiC, and compound semiconductors. We understand how dopant distributions, interface sharpness, and trace contamination affect real-world power device performance, and they work closely with clients to provide a meaningful analysis rather than raw numbers.

By combing advanced instrumentation with expert interpretation, EAG Laboratories delivers actionable insights that help improve device reliability.

Join us “In the Lab” to learn how investigative analytical chemistry can help solve your product or manufacturing line problems!

Join us “In the Lab” to learn how investigative analytical chemistry can help solve your product or manufacturing line problems!

February 15, 2024

Please join us for coffee and conversations! Enjoy a cup of coffee and pastries as you get to know our technical experts.

EAG divides FA tasks into three levels. In each level, we employ optimal techniques for device characterization, defect localization, and root cause failure analysis.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.