Evolved Gas Analysis for Material Outgassing Characterization

All materials have trapped gasses inside. Learn how EAG utilizes Evolved Gas Analysis to analyze what gasses are being released.

Failure Analysis in Aerospace Advancements

Home » Failure Analysis in Aerospace Advancement

In 1903, the Wright brothers made history and presented the first aircraft capable of sustaining powered flight. Flight was made possible by the breakthrough invention of pilot operated wing-warping, crafted carefully by detailed research and incredible engineering.1 This success thus resulted in the birth of the aerospace industry.

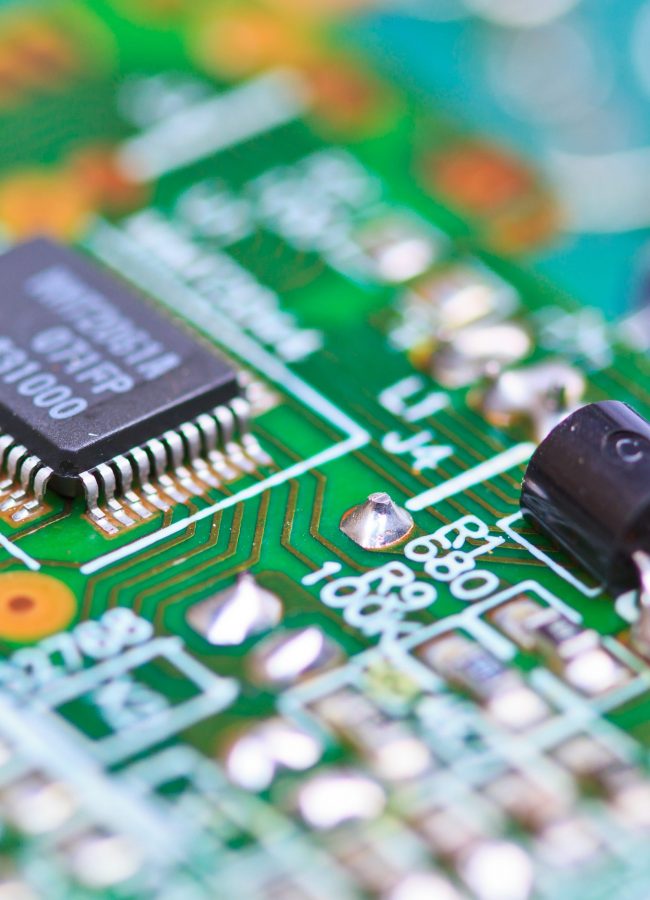

From 1903 to modern times, the industry has expanded into commercial airplanes, spacecrafts, satellites, missiles and more, consequentially resulting in increasingly more complex electronic systems. Although these technological advancements are welcomed and necessary in today’s climate, the complexities that come with development present a variety of new problems including quality and safety standards.

EAG can assist with your failure analysis needs.

In the aerospace industry, electronics are subjected to extreme environmental variables such as wide and sudden swings in temperature, strong vibrations, lightning strikes, a multitude of forces acting in different directions simultaneously, severe pressure differentials, moisture intrusion, and ionizing radiation. This can lead to potential issues with control systems, impair aircraft sensors, hinder communication systems, and even compromise structural integrity. To help solve these problems, EAG’s failure analysis experts use advanced analytical tools and proven methodologies to achieve high quality results and reliable engineering assessment.

Some examples of techniques and tools we can use:

EAG is a certified partner (ISO 9001:2015, ISO 17025, ITAR compliant, MIL standards compliant) and offers services to assist with the innovation of new high-performance electronics, collaborate during the iterative efforts of increasing long term reliability, and when necessary, perform comprehensive investigations to identify elusive failure mechanisms. We support innovation at every phase of the product cycle.

Our engineers are knowledgeable and experienced in today’s advanced technologies and are well equipped to help assist in your investigative needs.

1 Culick, F. E. C. (2003). The Wright brothers: first aeronautical engineers and test pilots. AIAA journal, 41(6), 985-1006.

All materials have trapped gasses inside. Learn how EAG utilizes Evolved Gas Analysis to analyze what gasses are being released.

In vitro biocompatibility testing is a powerful tool in the risk assessment of wearable devices. View our webinar to learn more!

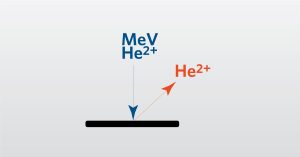

APT is a nanoscale materials analysis technique that provides 3D spatial imaging and chemical composition measurements with high sensitivity simultaneously.

In this webinar we will focus on Rutherford Backscattering Spectrometry (RBS) which is a thin film analysis technique

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.