X-Ray Fluorescence (XRF)

Home » Our Techniques » Spectroscopy » XRF

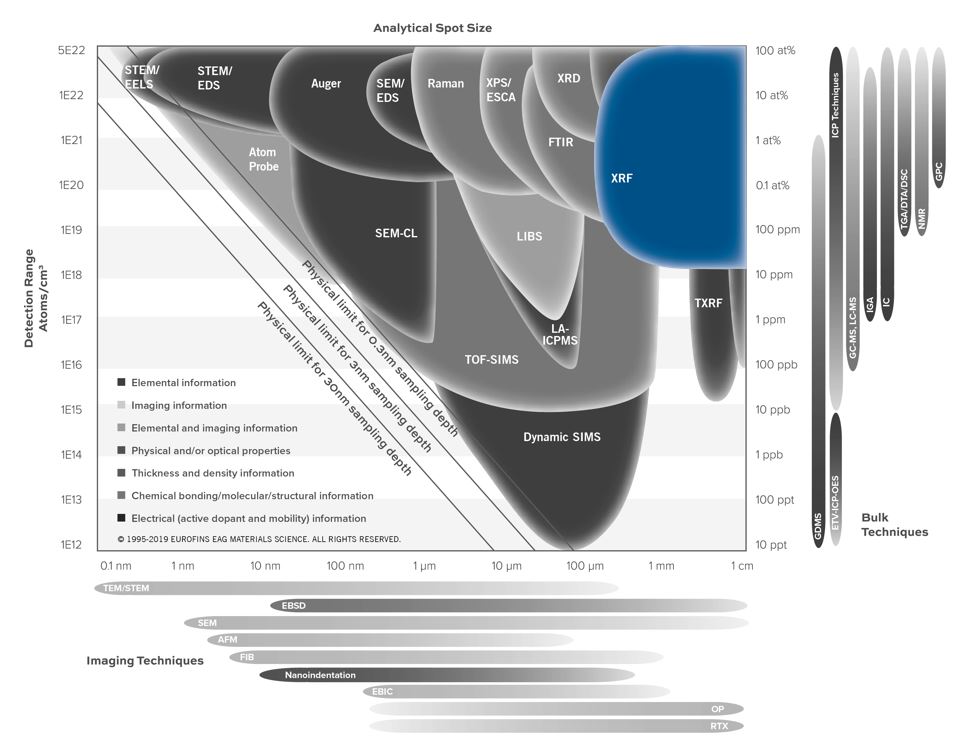

X-ray Fluorescence (XRF) is a non-destructive technique that is used to quantify the elemental compositions of materials and to measure film thickness and composition. X-rays are used to excite the sample, causing the emission of X-rays with energies characteristic of the elements present.

XRF is capable of detecting elements from B-U in concentrations from the ppm range to 100%. In addition, measurement of copper is possible using this technique. Because X-rays are used to excite the sample, analysis depths from less than a nanometer to several millimeters can be achieved, depending on the material.

Through the use of appropriate reference standards, or fundamental parameters (FP) when standards aren’t available, XRF can accurately quantify the elemental composition of most materials.

Five XRF systems are available: four wavelength dispersive instrument (WDXRF) and an energy dispersive instrument (EDXRF), with the main difference being the way in which the X-rays are separated and measured. WDXRF has very good energy resolution, which leads to fewer spectral overlaps and improved background intensities. EDXRF has higher signal throughput, which enables small area analysis or mapping.

Ideal Uses of XRF

- Firstly, measuring film thickness and composition from the angstrom range up to several micrometers

- Secondly, for general elemental identification and quantitation in most materials, including glass, metals, ceramics, polymers, or residues

- Thirdly, for the identification of specific metal alloys or types of glass

- Fourthly, for trace level analysis for contaminants in solid or liquid samples

- Fifthly, when identifying and quantifying inorganic fillers in polymers

- Also, for nondestructive analysis of large sputter targets

- Lastly, for nondestructive analysis of thin films on wafers up to 300 mm diameter

Strengths

- Non-destructive

- Whole wafer analysis (up to 300 mm) as well as wafer pieces and small samples

- EDXRF analysis of very large samples: 15x15x10 cm (LxWxH)

- WDXRF analysis of very large samples: 400 mm diameter, 50 mm thickness, 30 kg mass

- Thickness and composition of multilayer film stacks

- Can analyze areas as small as ~30 µm (EDXRF) or 500 µm (WDXRF)

- Can analyze any solid material and some liquids

- Sampling depth ranging from less than a nanometer to several millimeters depending on the material

Limitations

- Firstly, it cannot detect elements lighter than Na using EDXRF

- Secondly, it cannot detect elements lighter than B using WDXRF (Be can be detected, but only in copper)

- Thirdly, the highest accuracy measurements require reference standards similar in composition and/or thickness to the test sample

XRF Technical Specifications

- Signal Detected: X-rays

- Elements Detected: B-U (WDXRF); Na-U (EDXRF)

- Detection Limits: 1 ppm – 100 ppm for most elements

- Imaging/Mapping: Yes (up to 6×10 cm area)

- Lateral Resolution/Probe Size: 500 µm, 1 mm, 6 mm, 10 mm, 20 mm, 26 mm, 30 mm or 37 mm (WDXRF); 30 µm, 1 mm, 2 mm (EDXRF)

Related Resources

Would you like to learn more about using X-Ray Fluorescence (XRF)?

Contact us today for your X-Ray Fluorescence (XRF) needs. Please complete the form below to have an EAG expert contact you.